Protected seam bottom plate upward comb-shaped drilled hole gas extraction method

A protected layer and gas drainage technology, applied in the direction of gas discharge, earth drilling, mining equipment, etc., can solve the problems of increasing the cost of extraction, affecting the mining efficiency and cycle, and the large amount of drilling engineering, so as to improve the gas consumption. Drainage efficiency, shorten the mining cycle, reduce the effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

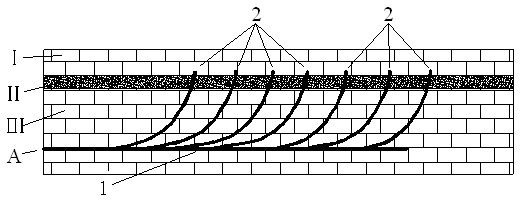

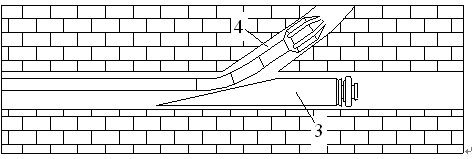

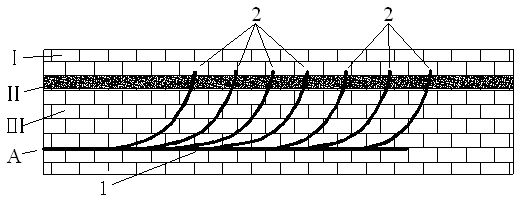

[0017] Such as figure 1 As shown, in the protected layer floor comb-shaped drilling gas drainage method of the present invention, firstly, a drilling field A is arranged in the protected layer bottom plate III, and a main hole 1 is first drilled in the drilling field A along the direction of the working face, and the main hole 1 The vertical distance between the horizontal position and the protected layer II is 15-25m; stop drilling after the main hole 1 is drilled 15m, ream the main hole 1, install the sealing pipe in the reaming hole, install the sealing pipe The length of the main hole 1 is 8 ~ 15m; install the blowout preventer and the gas-water separator at the orifice; continue to drill the main hole 1 along the direction of the working face until the main hole 1 reaches the set depth; Insert the packing whipstock 3 to the innermost end, then set the position of the first forced deflection point from the inside to the outside, and use the bottom motor 4 with a small diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com