Martensite stainless steel anti-theft nut manufactured by anti-crisping quench hardening process

A technology of martensitic stainless steel and anti-theft nuts, which is applied to nuts, manufacturing tools, bolts, etc., can solve the problems of lack of anti-theft screws, theft and sale of facilities that are easy to be destroyed by terrorism, etc., and achieve the effect of simple structure, reliable anti-terrorism and obvious social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

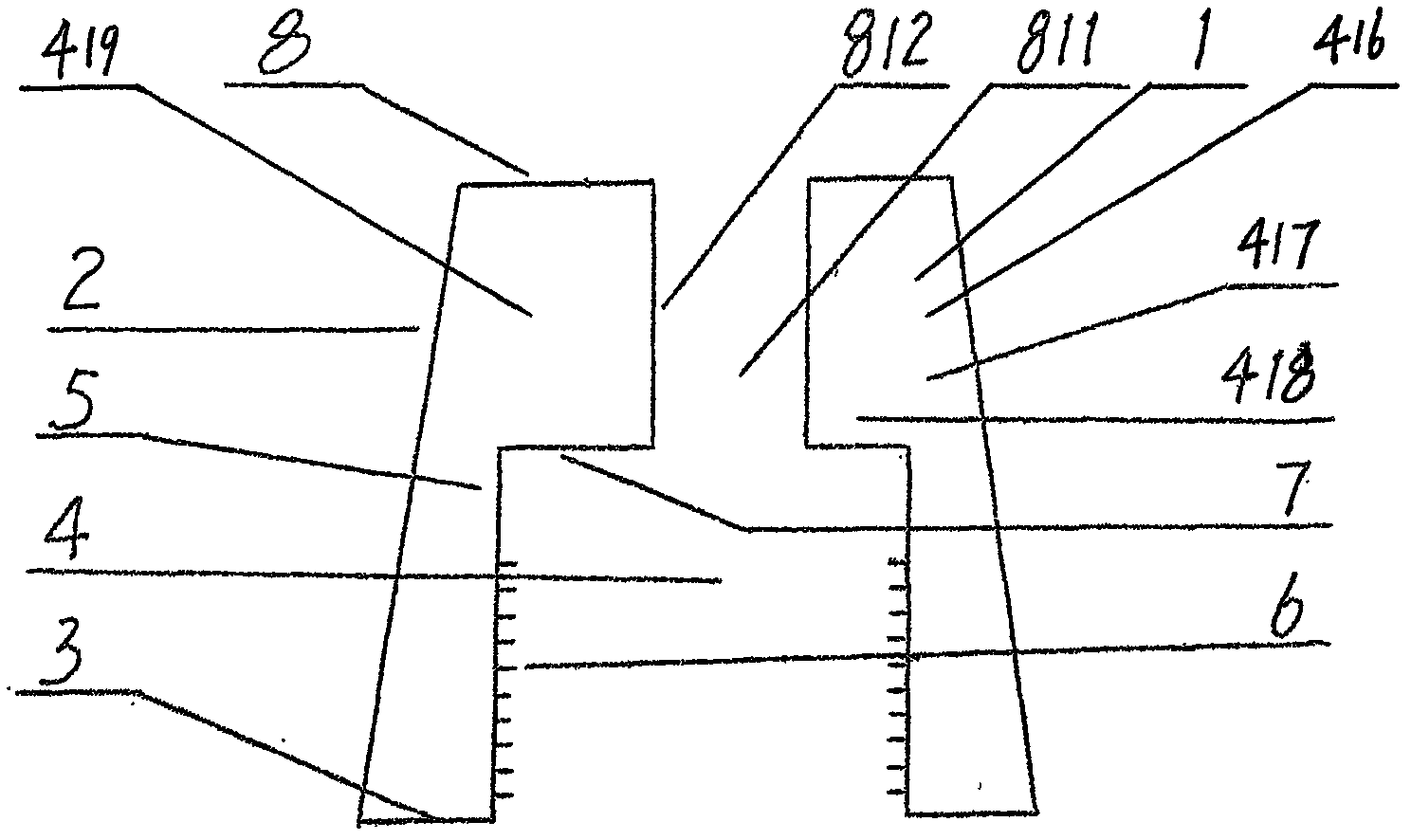

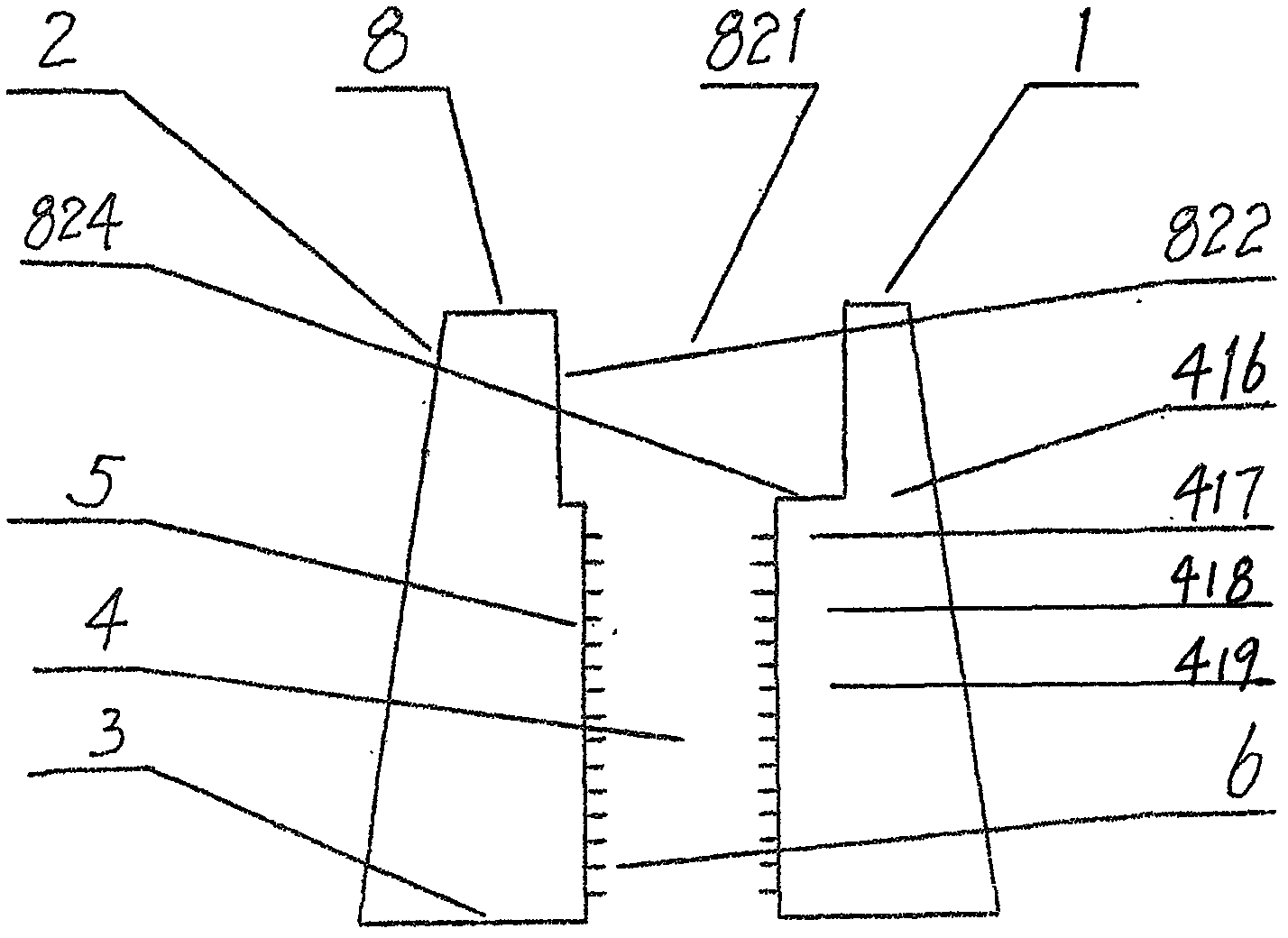

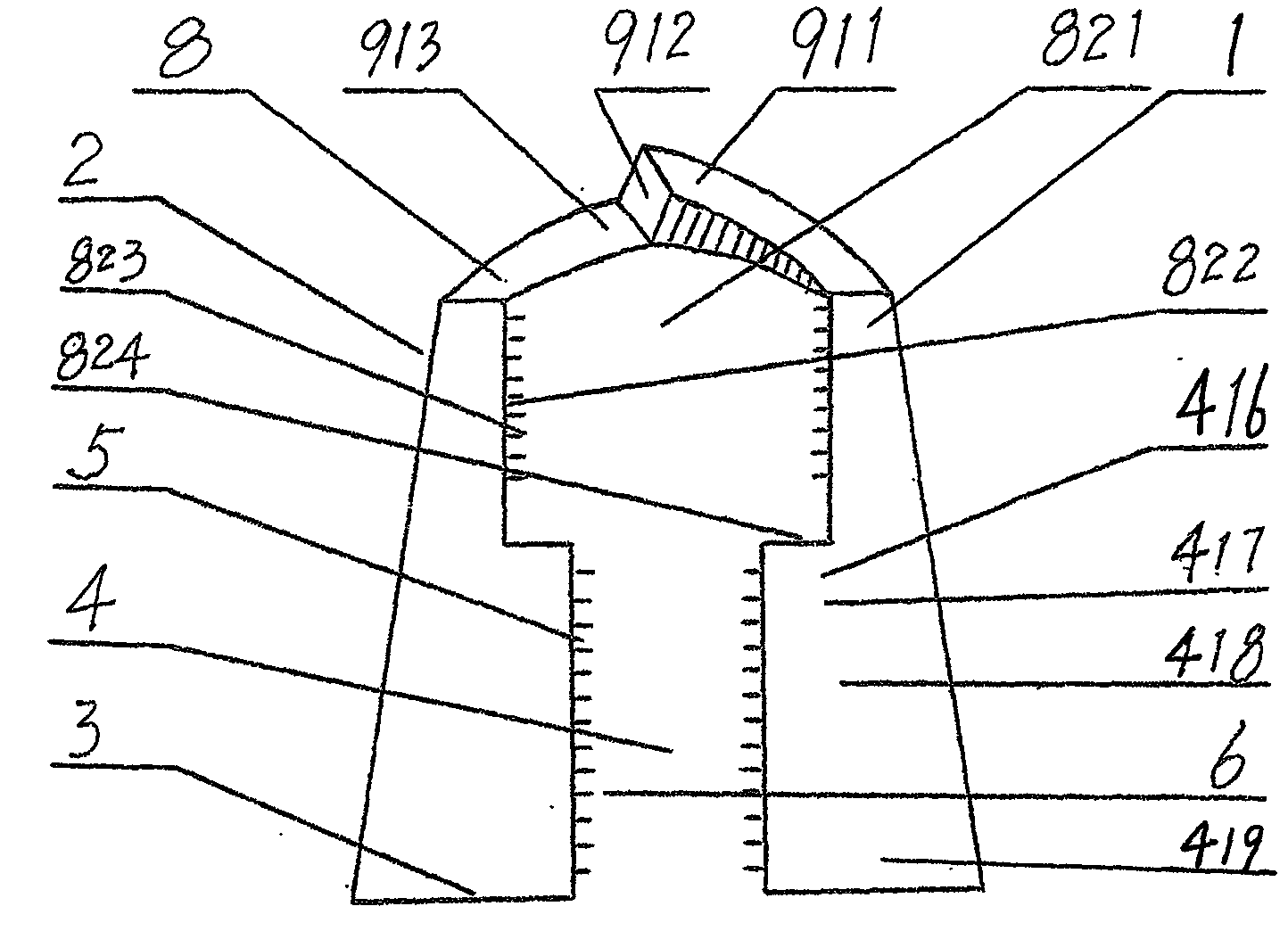

[0029] exist figure 1 Unquenched martensitic stainless steel anti-theft nut body 1 is respectively provided with nut outer circumference taper wall 2, nut bottom surface 3, nut bottom surface internal through hole 4, nut bottom surface internal through hole wall 5, nut bottom surface internal through hole wall 5, and nut bottom surface. Thread 6, inner through hole edge top 7 on the bottom surface of the nut, eccentric inner circular through hole 811 on the nut top surface and eccentric inner circular through hole wall 812 on the nut top surface 8 are provided on the nut top surface 8, for the 10th regular period to 1040°C ± 100°C parent body for the second conventional oil cooling to 0°C ± 40°C 415, the parent body for the third time at minus 80°C ± 70°C nitrogen freezing for 2.5 hours ± 2 hours 416, after the third pass at minus 80°C ± 70°C nitrogen After freezing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com