Limited angular displacement rolling post rolling thrust simulation screw for disc brake pressurization

A limited-angle, helical technology, applied in the direction of brake actuators, gear shifting mechanisms, mechanical equipment, etc., can solve the problems of high manufacturing cost, frequent failures, burst pipes, etc., and achieve the effect of reducing processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

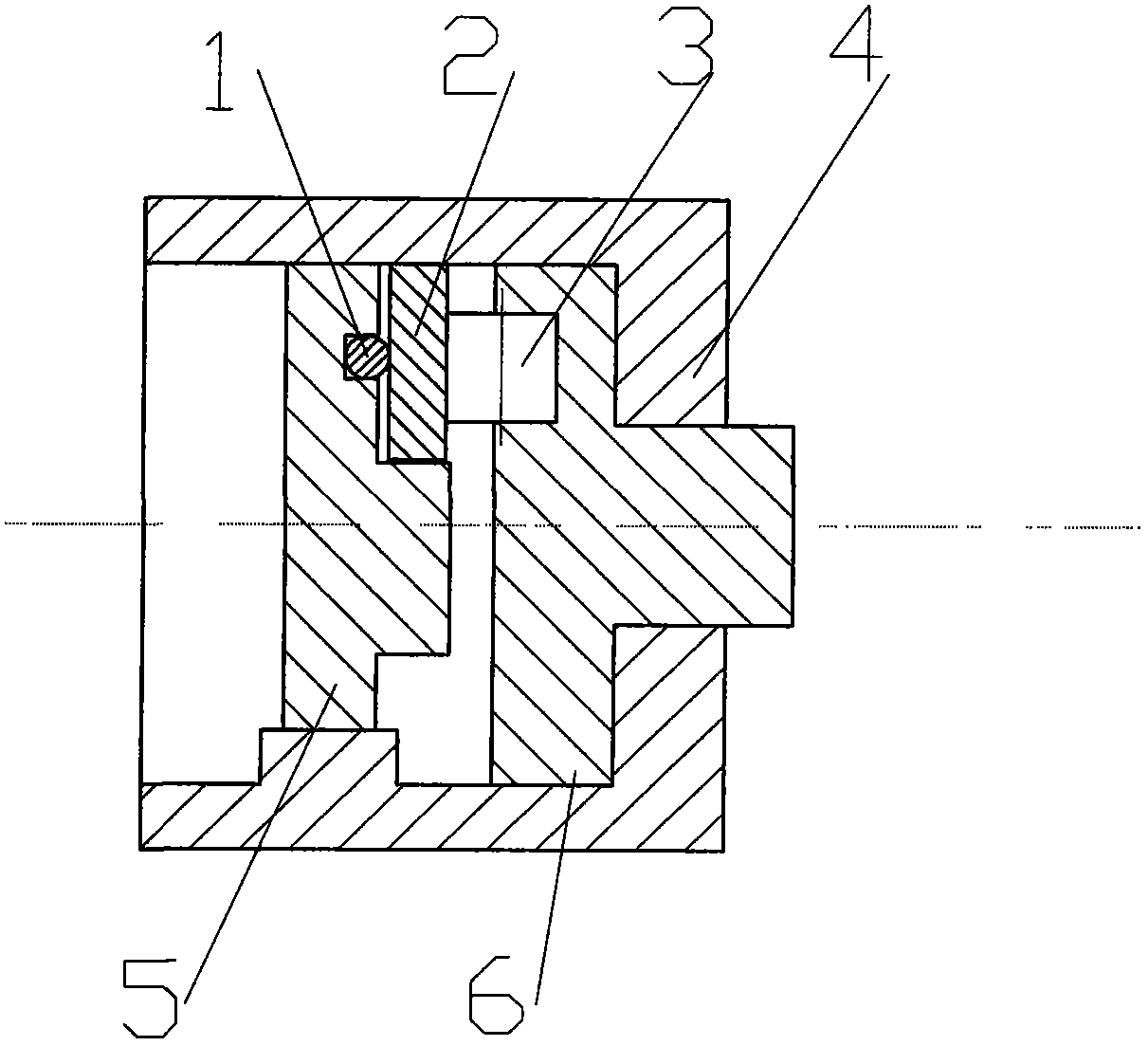

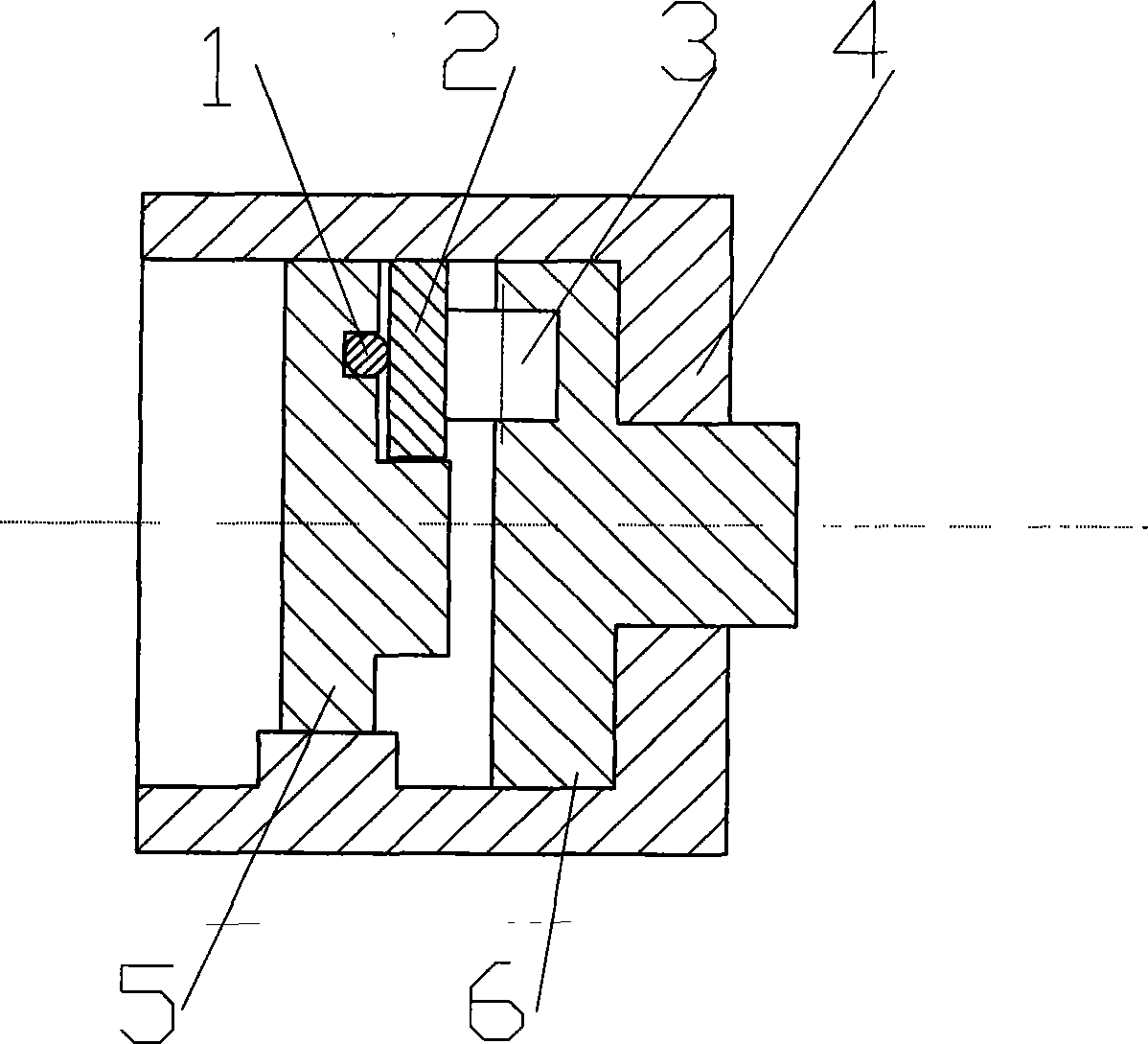

[0008] In the figure, the end faces of the fixed helix (5) and the driving helix (6) all have three inclined grooves with the same inclination, and they are connected end to end from shallow to deep to form an equilateral triangle. Three needle rollers (1) are put into the groove of fixed screw (5) along. Six rollers (3) are divided into three groups and vertically put into the driving screw (6) groove respectively. Three rocking plates (2) are placed on the needle rollers (1) in a fan shape. When the driving screw (6) rotates counterclockwise, the roller (3) rolls between the driving screw (6) and the rocking plate (2), and the rocking plate (2) rotates with the driving screw (6), and the needle ( 1) Make a small amount of rolling on the top to form a dynamic spiral surface and push the fixed spiral forward. The two rollers (3) in each groove of the active screw can make the rocking plate (2) parallel to the plane of the bottom of the groove, and share one needle (1). The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com