Heat exchanger air inlet buffer structure

A technology of buffer structure and air inlet, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problem of loose expansion joints between heat exchange tubes and tube sheets, economic losses in maintenance and replacement, and damage to heat exchange. Condition and other problems, to achieve the effect of reducing destructiveness, easy production, and obvious depressurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

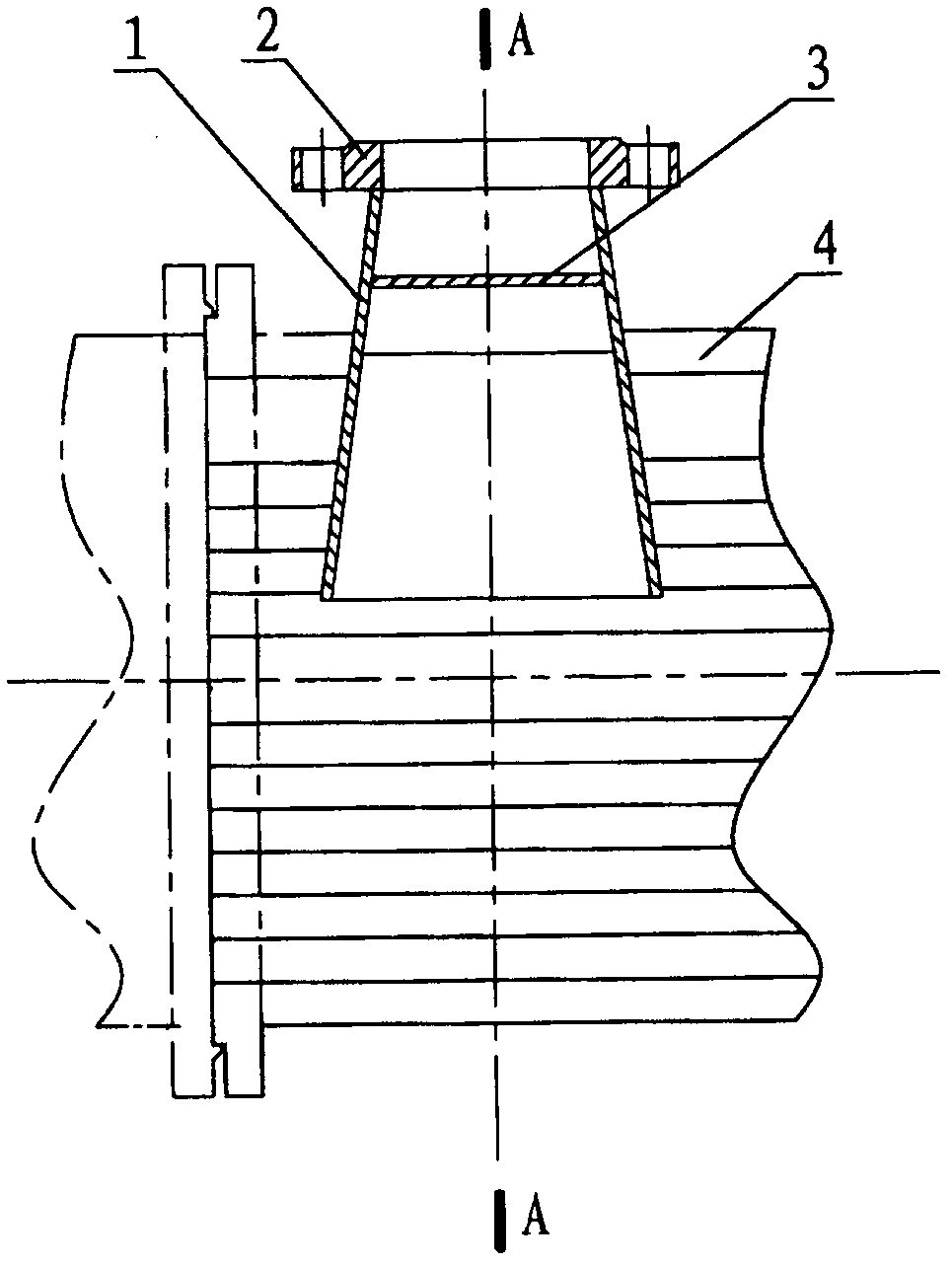

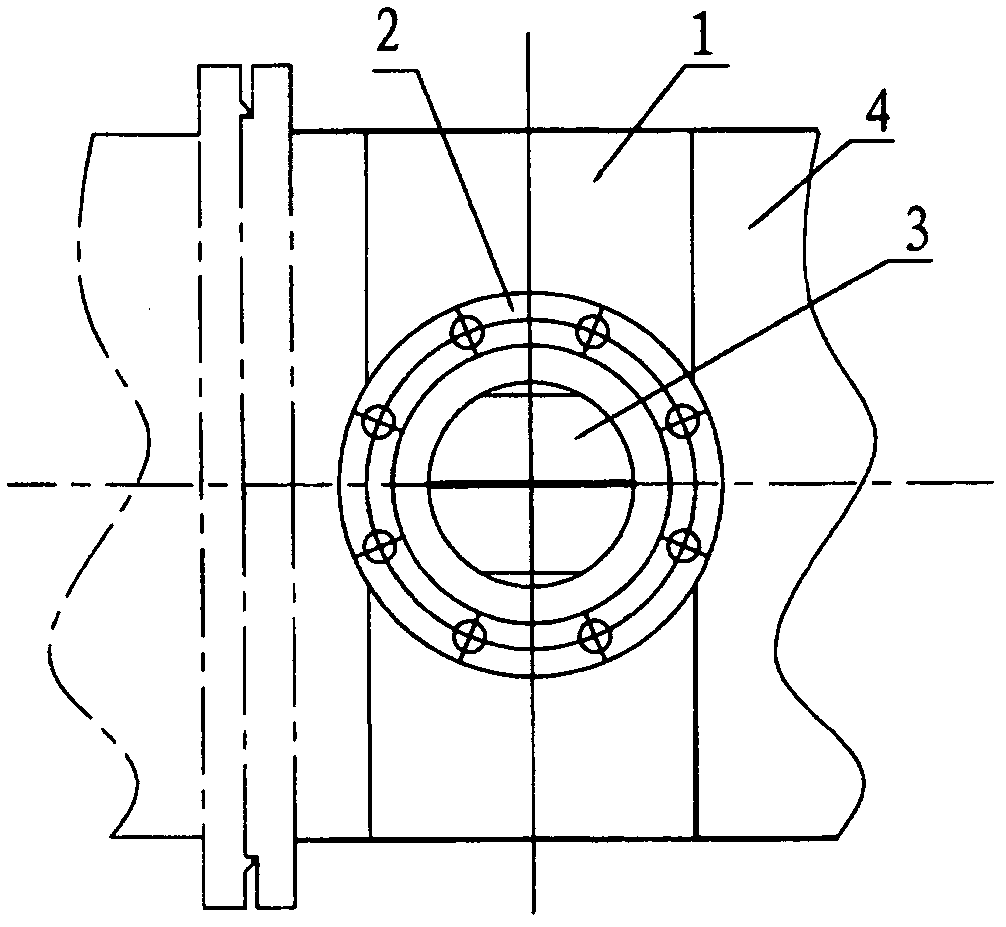

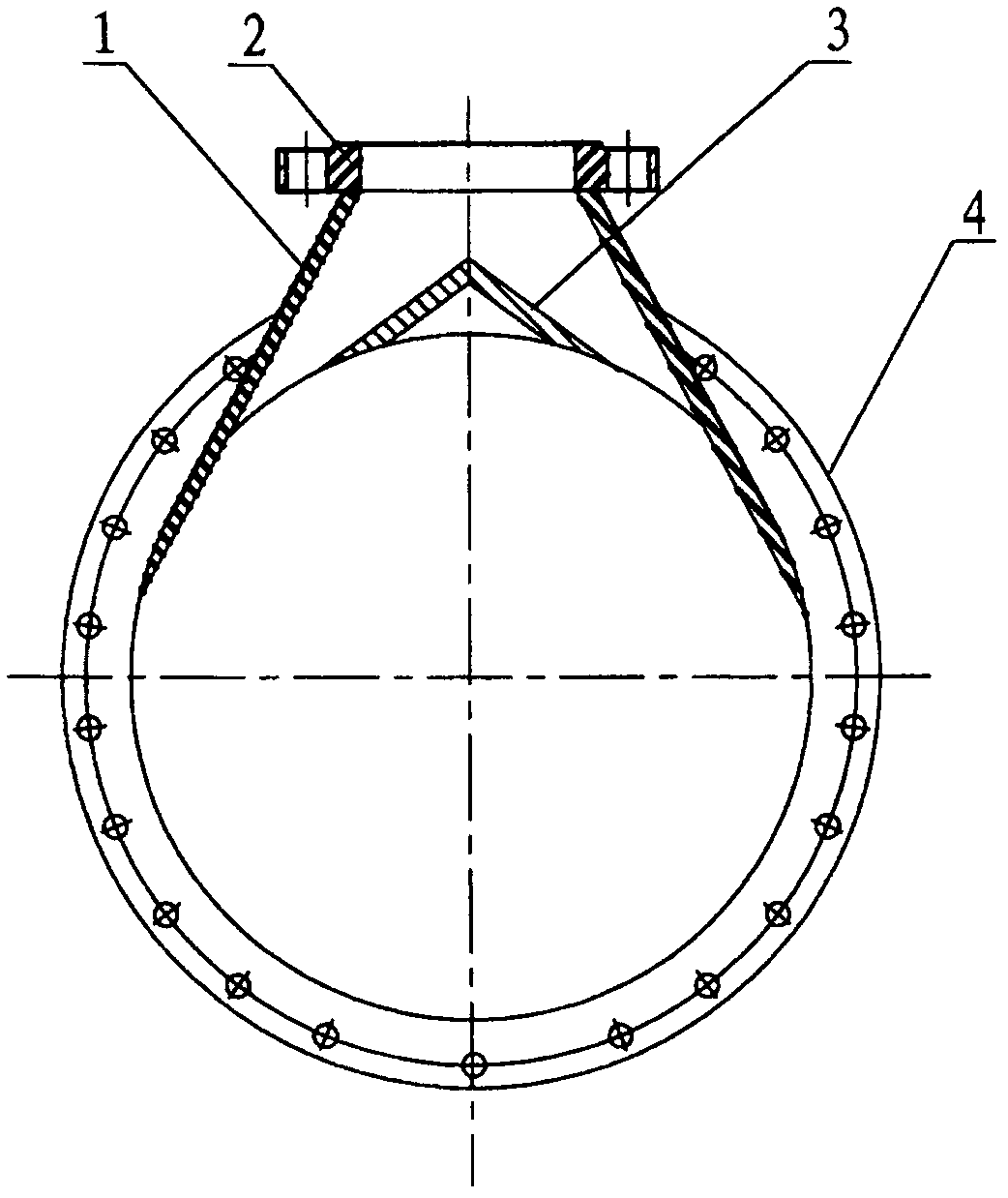

[0015] figure 1 The air inlet buffer structure of the heat exchanger shown includes an air inlet and a deflector 3 fixedly connected to the side cylinder wall of the displacement section 4 . The air inlet is a rectangular tapered tube 1 with a large inside and a small outside. The flange 2 connected to the outside is arranged at the small end of the rectangular tapered tube 1 , and the other end is in sealing connection with the cylinder wall of the replacement section 4 . image 3 with figure 2 The deflector 3 shown is a rectangular plate bent in the center to form a corner plate. In this embodiment, it is bent into a 120° angle plate with the outwardly convex bending seam facing outward. The deflector 3 constitutes a frontal barrier and plays a buffering role. In addition, two diffused passages are formed between both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com