Pile foundation control blasting excavation method of integral-plate rocky area

A technology for controlling blasting and rock areas, applied in blasting and other directions, can solve problems such as rock cracking around the pile foundation and at the bottom of the pile, reduce rock clamping force, and weaken strong vibration of blasting, so as to reduce rock clamping force and weaken blasting The effect of strong vibration and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention provides a pile foundation controlled blasting excavation method for a whole slab of rock area, comprising the following steps:

[0019] S1. Excavate and level the entire rock area, and locate the pile foundation;

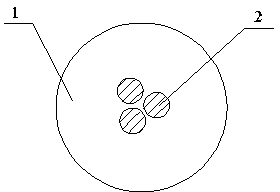

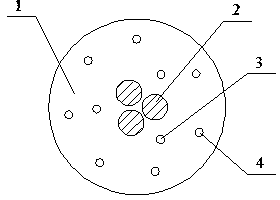

[0020] S2. Drill several pile core holes 2 in the center of the positioned pile foundation to form a pile core hollow area;

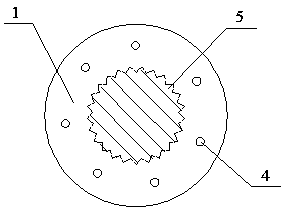

[0021] S3. Drill at least two circles of holes evenly arranged in the outer ring of the hollow area of the pile core, and obtain several circles of blastholes that are evenly arranged in the circumferential direction and arranged in an intersecting arrangement, including the inner ring blasthole 3 of the innermost ring and the holes evenly distributed in the inner ring. A number of outer ring blastholes around the blasthole;

[0022] S4. Load rock emulsion explosives and millisecond delay detonators into all blastholes, and the detonation time of the detonators located in the outer blastholes in every two adjacent bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com