Manufacturing method of pixel structure

A manufacturing method and pixel structure technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as inability to meet users, complicated process, and inability to reduce production cost and output rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to enable your examiner to have a further understanding and understanding of the structural features and achieved effects of the present invention, a description of preferred embodiments and diagrams are provided.

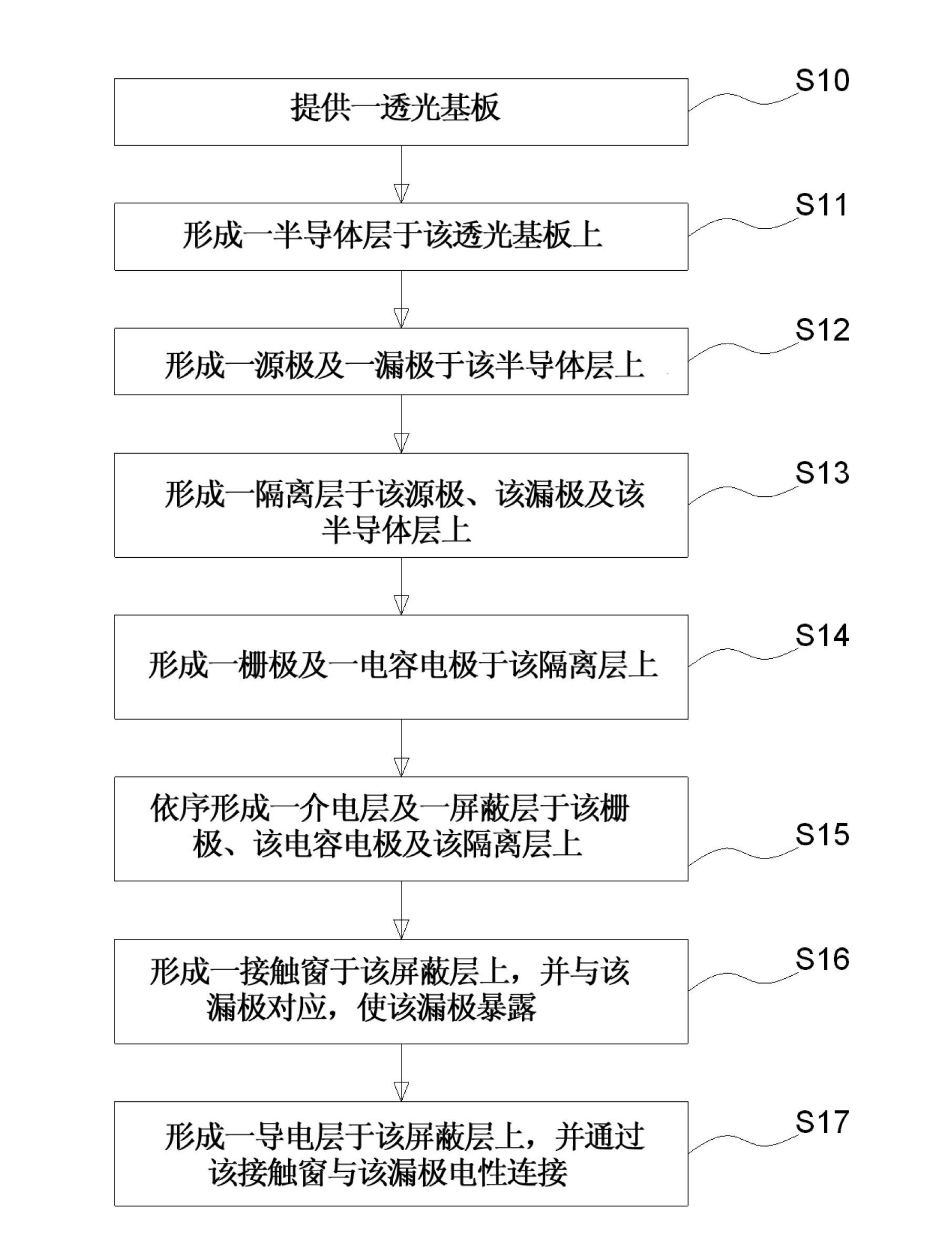

[0065] see figure 1 , Figure 2A and Figure 2B , are respectively a schematic diagram of the manufacturing process of the pixel structure of the present invention, a schematic cross-sectional structural diagram of step S10 of the present invention, and a schematic top view structural diagram of step S10 of the present invention. As shown in the figure: the present invention provides a thin film transistor and a pixel structure and a manufacturing method thereof. The manufacturing method of the pixel structure is to firstly perform step S10 to provide a light-transmitting substrate 10, and the material of the light-transmitting substrate 10 includes glass, quartz Or plastic, but depending on design requirements, the light-transmitting substrate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com