Vehicle body panel joining structure

A body panel and structure technology, applied in the field of body panel joint structure, can solve the problems of reduced impact load transferability, obstruction of connecting parts, increase in the number of parts, etc., and achieve the effect of improving the rigidity of the body and suppressing the reduction of the strength of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Next, an embodiment of the present invention will be explained based on the drawings.

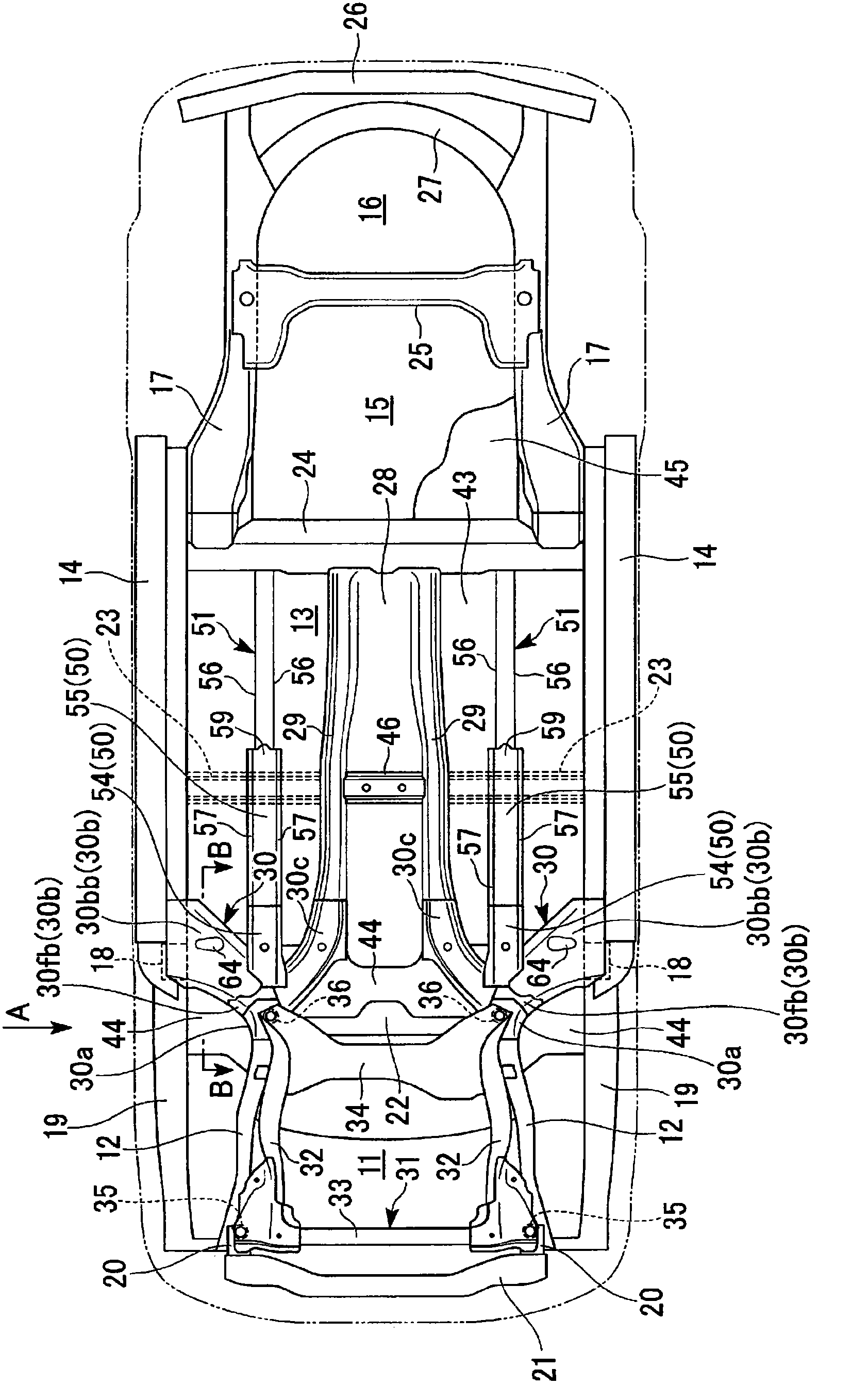

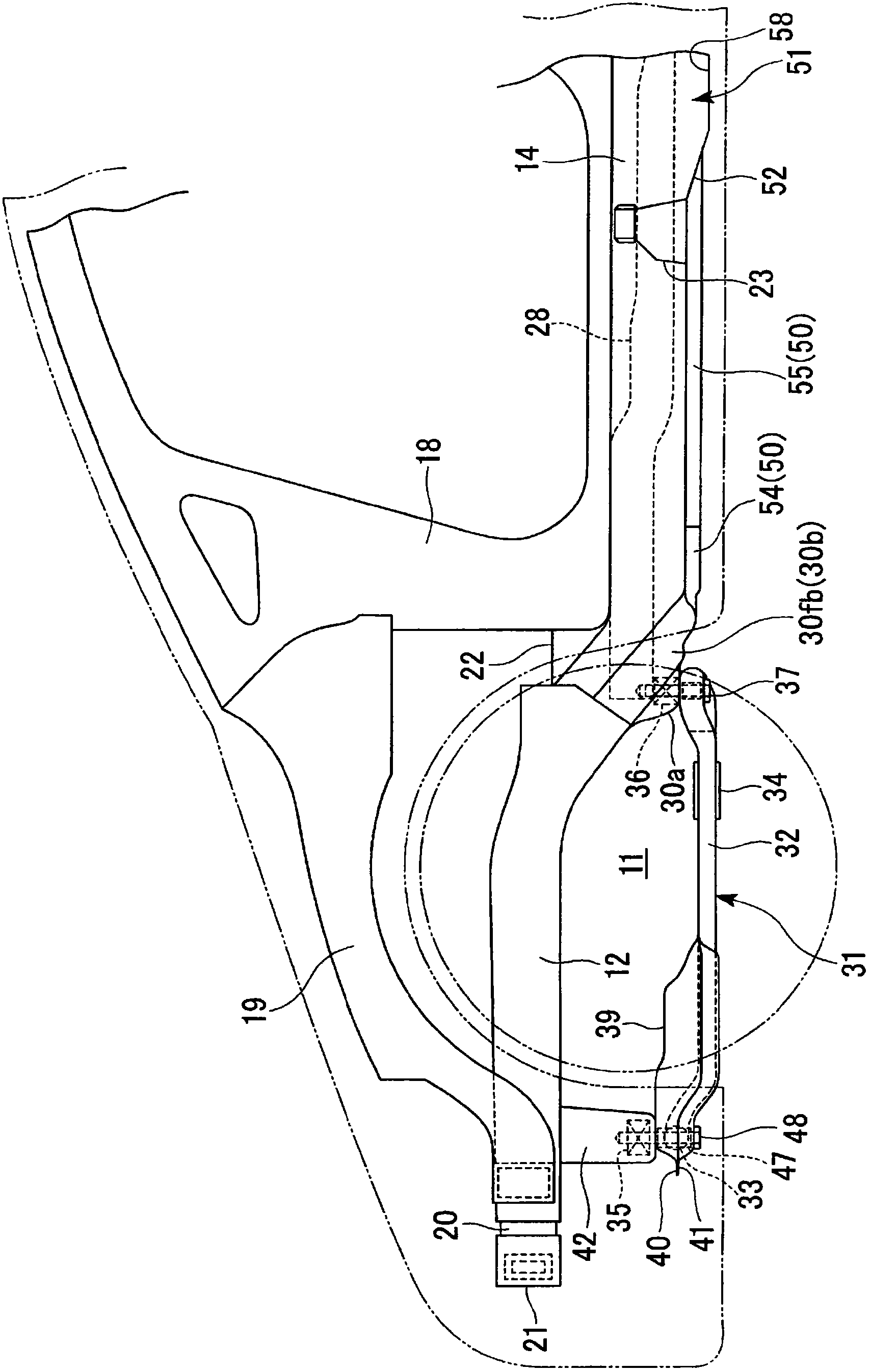

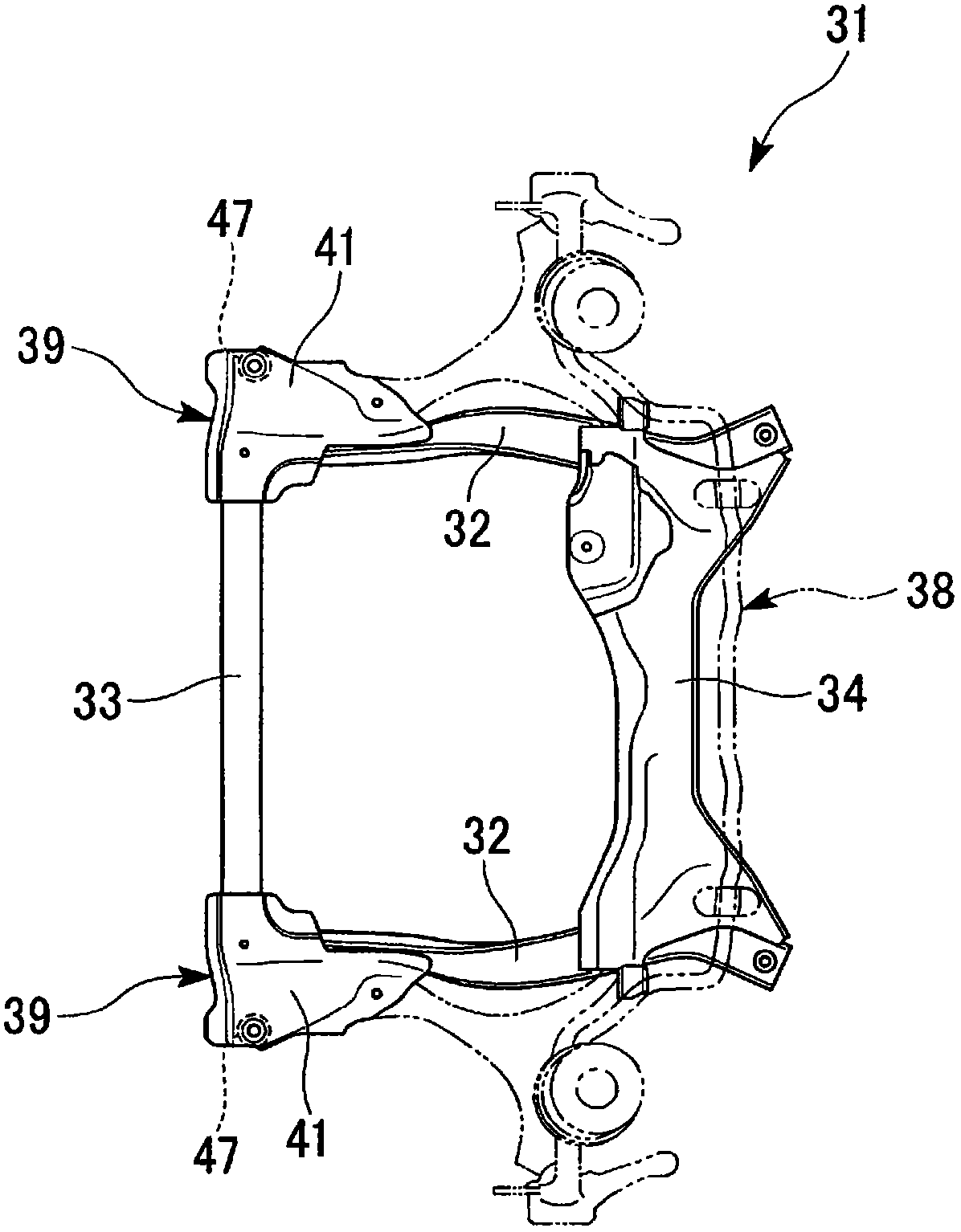

[0026] figure 1 Is a view of the car body viewed from the bottom surface, figure 2 Yes figure 1 The A-direction view. In addition, in figure 1 , figure 2 The outline of the car body is indicated by a dotted line in the middle. Such as figure 1 , figure 2 As shown, the vehicle body frame has: a pair of left and right closed cross-sectional structure front frames 12, 12 extending along the left and right sides of the engine room 11 and extending in the front and rear direction of the vehicle body; A pair of left and right side members 14 and 14 with a closed cross-sectional structure extending in the front and rear direction of the vehicle body; extending along the left and right sides of the fuel tank storage portion 15 and the luggage compartment 16 in the front and rear direction of the vehicle body , A pair of left and right rear frames 17 and 17 with closed cross-section structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com