Processing method of instant vacuum dried penaeus aztecus

A processing method and vacuum drying technology, which is applied in the field of food processing, can solve problems such as long drying time, Maillard browning, and product quality degradation, so as to ensure hygiene and safety, prevent adverse effects, and prevent color browning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

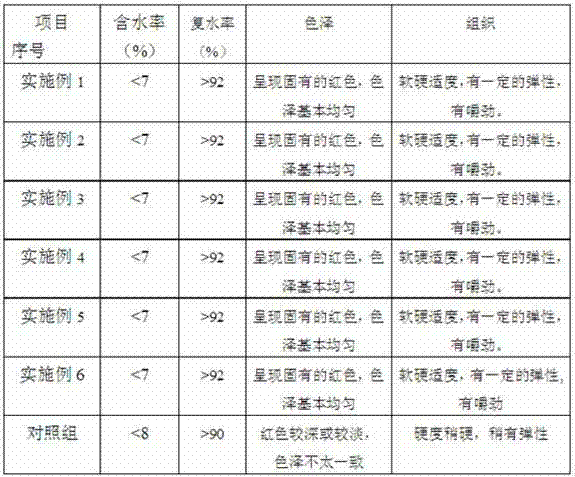

Examples

Embodiment 1

[0023] (1) Material selection: Red shrimps that grow naturally in reservoirs and lakes are used. The length from the eyes of the shrimp to the root of the tail is 5cm-10cm. Miscellaneous shrimp, weeds, spoiled shrimp and shrimp with unsatisfactory freshness are removed.

[0024] (2) Water washing: Washing with water repeatedly rinses the sludge and floating grass on the skin of the red shrimp to keep the raw materials clean.

[0025] (3) Boil in water: Take 1Kg of washed red shrimp, pour it into boiling water in a sandwich pot, and cook in water for 8 minutes until the red shrimp is fully cooked.

[0026] (4) Vacuum marinating: Soak the cooked red shrimp in the seasoning liquid. It is advisable that the seasoning liquid is submerged in the red shrimp. Under the condition of vacuum degree of 70000Pa, the pickling time is 6 hours; the seasoning liquid is composed of the following mass percentages: The composition of raw materials: 2% to 4% salt, 0.25% to 0.45% monosodium glutam...

Embodiment 2

[0031] (1) Material selection: Red shrimps that grow naturally in reservoirs and lakes are used. The length from the eyes of the shrimp to the root of the tail is 5cm-10cm. Miscellaneous shrimp, weeds, spoiled shrimp and shrimp with unsatisfactory freshness are removed.

[0032] (2) Water washing: Washing with water repeatedly rinses the sludge and floating grass on the skin of the red shrimp to keep the raw materials clean.

[0033] (3) Boil in water: Take 1Kg of washed red shrimp, pour it into boiling water in a sandwich pot, and cook in water for 9 minutes until the red shrimp is fully cooked.

[0034] (4) Vacuum marinating: Soak the cooked red shrimp in the seasoning liquid. It is advisable that the seasoning liquid is submerged in the red shrimp. Under the condition of vacuum degree of 70000Pa, the pickling time is 5.5h; the seasoning liquid is made of the following mass percentage: The content of raw materials: 2% ~ 4% salt, 0.25% ~ 0.45% monosodium glutamate, 0.5% ~ 1....

Embodiment 3

[0039] (1) Material selection: Red shrimps that grow naturally in reservoirs and lakes are used. The length from the eyes of the shrimp to the root of the tail is 5cm-10cm. Miscellaneous shrimp, weeds, spoiled shrimp and shrimp with unsatisfactory freshness are removed.

[0040] (2) Water washing: Washing with water repeatedly rinses the sludge and floating grass on the skin of the red shrimp to keep the raw materials clean.

[0041] (3) Boil in water: Take 1Kg of washed red shrimp, pour it into boiling water in a sandwich pot, and cook in water for 10 minutes until the red shrimp is fully cooked.

[0042](4) Vacuum marinating: Soak the cooked red shrimp in the seasoning liquid. It is advisable that the seasoning liquid is submerged in the red shrimp. Under the condition of vacuum degree of 80000Pa, the pickling time is 5.6h; the seasoning liquid is made of the following mass percentage: The content of raw materials: 2% ~ 4% salt, 0.25% ~ 0.45% monosodium glutamate, 0.5% ~ 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com