Method for fixing CO2 (carbon dioxide) by steel slag recycling

A technology of CO2 and resource utilization, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, can solve problems such as high energy consumption in the process, mismatch between chemical reaction and mass transfer, and limited transfer, so as to improve the performance of steel slag Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

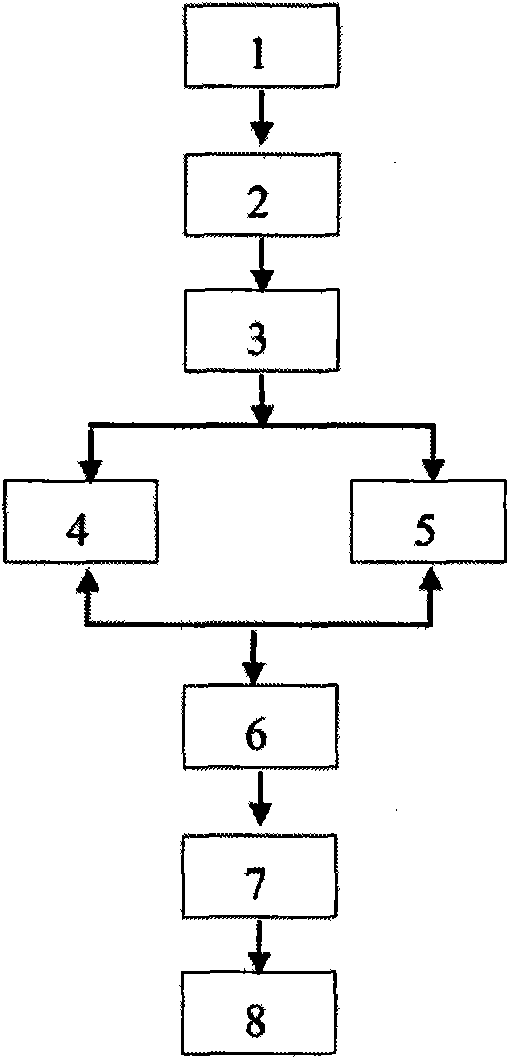

Method used

Image

Examples

Embodiment 1

[0018] 100-ton converter, water quenching of steel slag to fix CO 2 process, the water quenching pressure is 0.3MPa, the ratio of slag to water is 1:10, CO 2 The working pressure is 0.3MPa, and the gas consumption per ton of slag is 35Nm 3 , the processing capacity is 3t / min. Using this method for 1 hour, each ton of steel slag can fix CO 2 It is 187kg.

Embodiment 2

[0020] 300-ton converter, steel slag water quenching to fix CO 2 process, the water quenching pressure is 0.5MPa, the ratio of slag to water is 1:15, CO 2 The working pressure is 0.6MPa, and the gas consumption per ton of slag is 60Nm 3 , the processing capacity is 7t / min. Using this method for 1 hour, each ton of steel slag can fix CO 2 It is 250kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com