Polyvinyl chloride (PVC) molding machine and molding mould

A molding machine and leak-proof technology, applied in the field of trademark molding and production, can solve the problems of flow marks, large cost and material leakage, and achieve the effects of reducing energy consumption, clear contours, and favorable positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

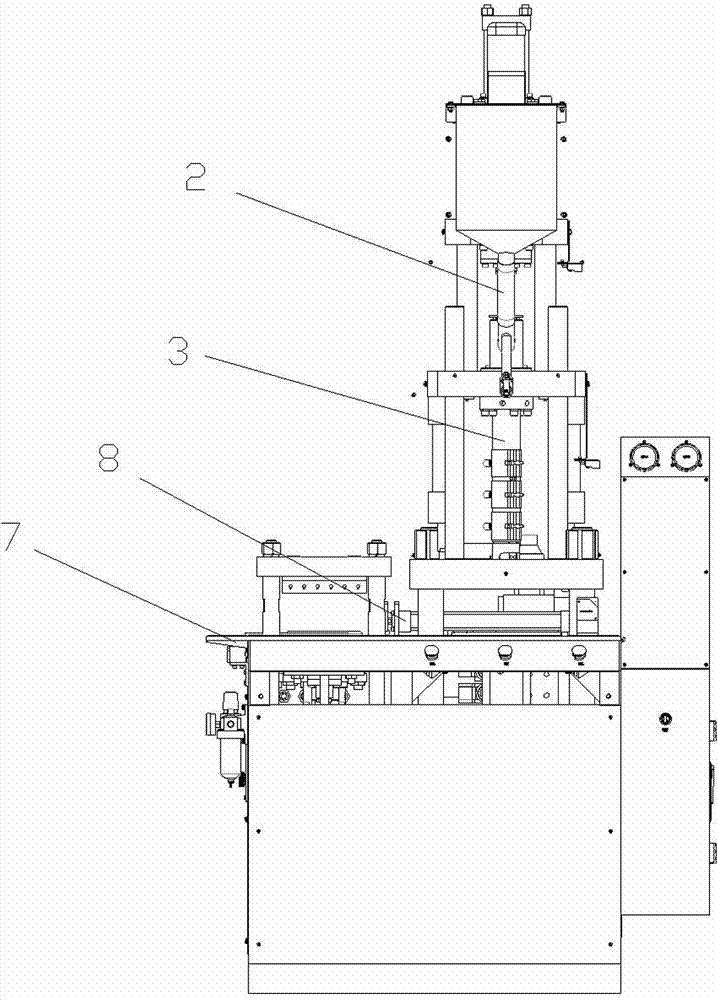

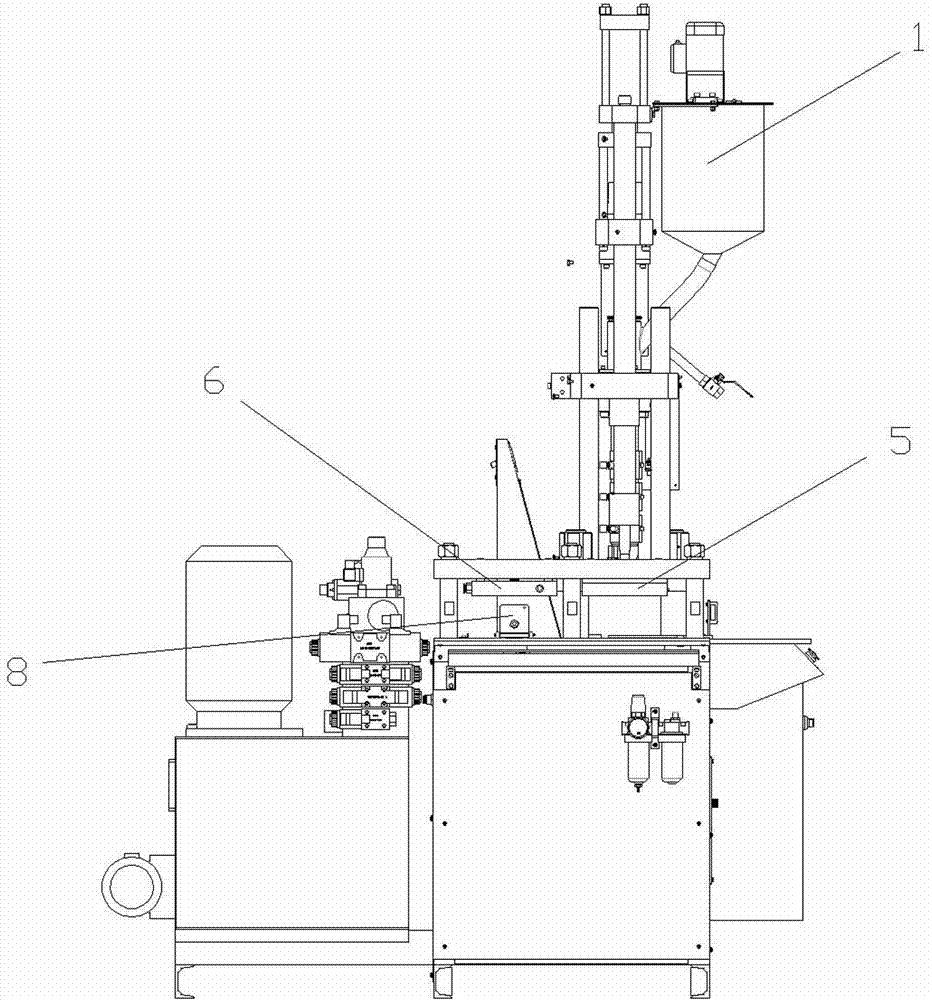

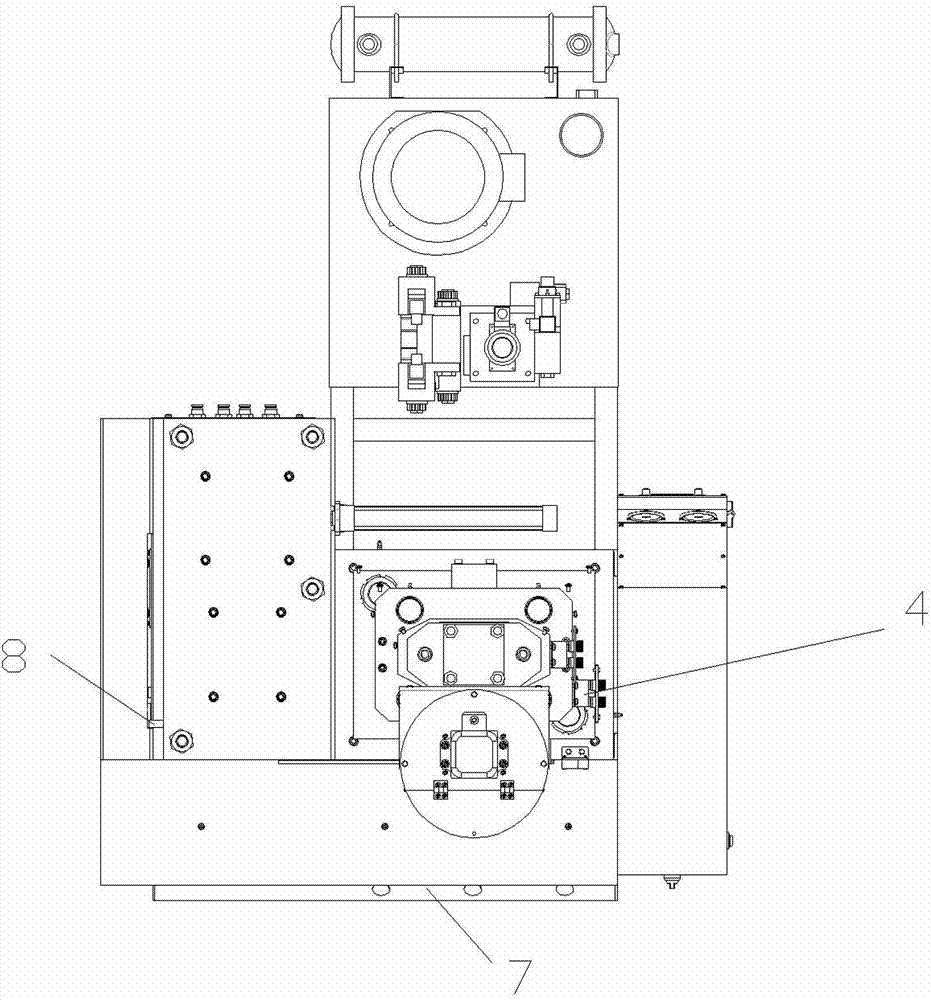

[0016] PVC forming machine of the present invention, such as figure 1 As shown, it includes a liquid hopper 1, a feed screw 2, a temperature-controllable barrel 3, a first push plate 4, a heating plate 5 and a cooling plate 6 in the temperature-controlled channel, and the end of the temperature-controllable barrel 3 is a leak-proof injection mouth. Figure 4 For the existing injection port, different from the traditional leak-proof injection port, the present invention is based on the injection of liquid material such as Figure 5 As shown, it includes a leak-proof screw sleeve tip 31 and a leak-proof sleeve 32 tightly fastened to the opening end of the leak-proof screw sleeve tip, and a leak-proof bead 33 and a leak-proof spring are included between the leak-proof screw sleeve tip 31 and the leak-proof sleeve 32 34. The anti-leakage bead 33 is blocked by the anti-leakage spring at the opening of the tip of the leak-proof screw sleeve. Due to the elasticity of the spring, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com