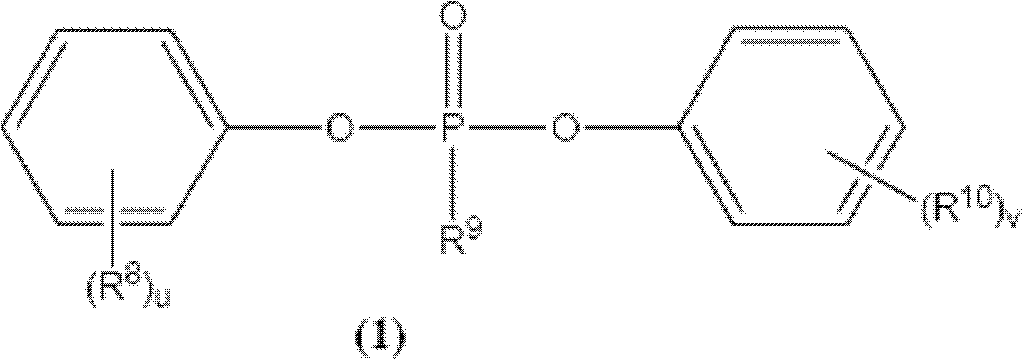

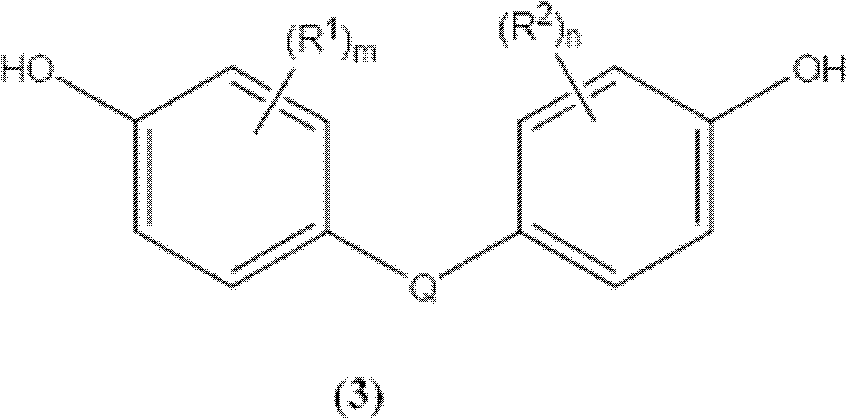

Poly (block-phosphonato-ester) and poly (block-phosphonato-carbonate) and methods of making same

A polyphosphonate and phosphonooxy technology, applied in the fields of poly and poly and its preparation, can solve the problems of reduced optical transparency, no control of polyphosphonate block size, darkening of color and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] 10 g low molecular weight oligomeric phosphonate (with 1190 g bisphenol A, 18.5 mole percent excess phosphonic acid diester (1595.5 g, methyl diphenoxy-phosphine oxide), 0.6 mole percent low carbon branched compound 1, 1,1-tris(4-hydroxyphenyl)ethane (9.2 g) and sodium phenoxide catalyst (150 mg) dried overnight at 40 °C at 2 mbar were prepared by a melt transesterification process with a T of 90 °C. g and η of 110 rel ) and 30 g of high viscosity polycarbonate (bisphenol A based) (such as Makraolon 3103 from Bayer) and 12 mg of tetraphenylphosphonium phenol transesterification catalyst were combined in a vessel under reduced pressure at 300 °C for 2 hours to remove volatile reactions product. Films of the product cast from dichloromethane solutions after drying were characterized and determined to have a T of 133-134°C g , η of 1.28-1.29 rel and a phosphorus content of approximately 2.72%.

Embodiment 2

[0075] 9.2 g of low molecular weight oligomeric phosphonates (by adding 207.9 g of methyl diphenoxy-phosphine oxide and 177.2 g of bisphenol A, 21.4 g of trisphenol phosphate (trisphenol phosphate) and 0.054 g of phosphonium phenolate catalyst under heating and Under vacuum for 7 hours, 191.4 grams of T with 70°C were generated g and an η of 1.09 rel The product phosphonate oligomers to prepare low M w Phosphonate oligomer) was mixed with 30.8 g of Makrolon 3103 dried under reduced pressure at 80°C overnight and 12 mg of tetraphenylphosphonium phenolate catalyst, and heated at 300°C under vacuum for 2 hours to remove by-products formed. The resulting product was 39.8 g with a T of 140 °C g , η of 1.29 rel ; Infrared (IR) P-O_C peak at 935cm -1 and a poly(phosphonooxycarbonate) with a phosphorus content (measured) of 1.98%.

Embodiment 3

[0077] 10g low molecular weight oligomeric phosphonate (by 75.9 gram methyl diphenoxy-phosphine oxides and 32.2g resorcinol, 0.92g trisphenol phosphate and 24mg phenol tetraphenyl phosphonium catalysts are reacted under heating and reducing The first day under pressure (66.5 g of by-product removed) and the second day of reaction with 24 mg of phosphonium phenolate catalyst under heat and reduced pressure (5.8 g of by-product removed) yielded 35 g of T g and an η of 1.05 rel The low M w Resorcinol phosphonate oligomer) was mixed with 30 g of Makrolon 3103 dried overnight at 80° C. under reduced pressure and 12 mg of phosphonium phenolate catalyst, and heated at 300° C. under vacuum for 4 hours to remove by-products formed. The resulting is a T with a T of 109°C g , η of 1.27 rel , and a phosphorus content (measured) of 4.31% of a slightly yellowish poly(phosphonooxycarbonate).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com