Step-by-step returning recycling method of LF (Lactoferrin) refining slag in thermal state

A technology of refining slag and recycling process, which is applied in the field of steelmaking to achieve the effects of reducing refractory consumption, improving metal recovery rate, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

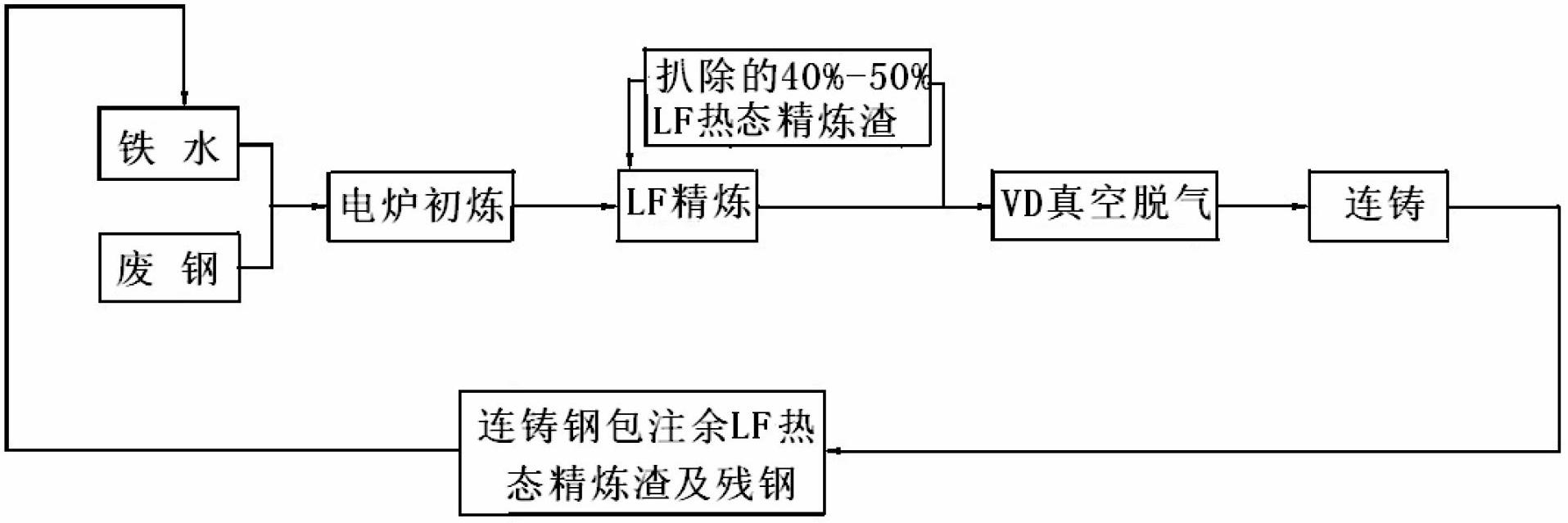

[0036] See figure 1 , smelting steel type 40Cr, the uncirculated furnace molten steel is refined by LF, and before VD vacuum degassing treatment, 40%-50% of LF hot refining slag is removed as the LF hot refining slag removed before VD treatment. The first step-by-step circulation of LF hot refining slag is directly poured into the ladle that circulates the molten steel in the first furnace to be refined by the LF furnace, replacing part of the pre-melted slag for LF refining, and re-creating new refining slag after four cycles , and continue to be recycled; after the continuous casting of each heat, the remaining LF hot refining slag injected into the ladle, that is, the second step-by-step cycle of the LF hot refining slag and the remaining steel is directly mixed into the electric furnace ladle, and added when the electric furnace is mixed with molten iron Electric furnace, replacing part of the slagging agent, is used for dephosphorization and desulfurization of electric fu...

Embodiment 2

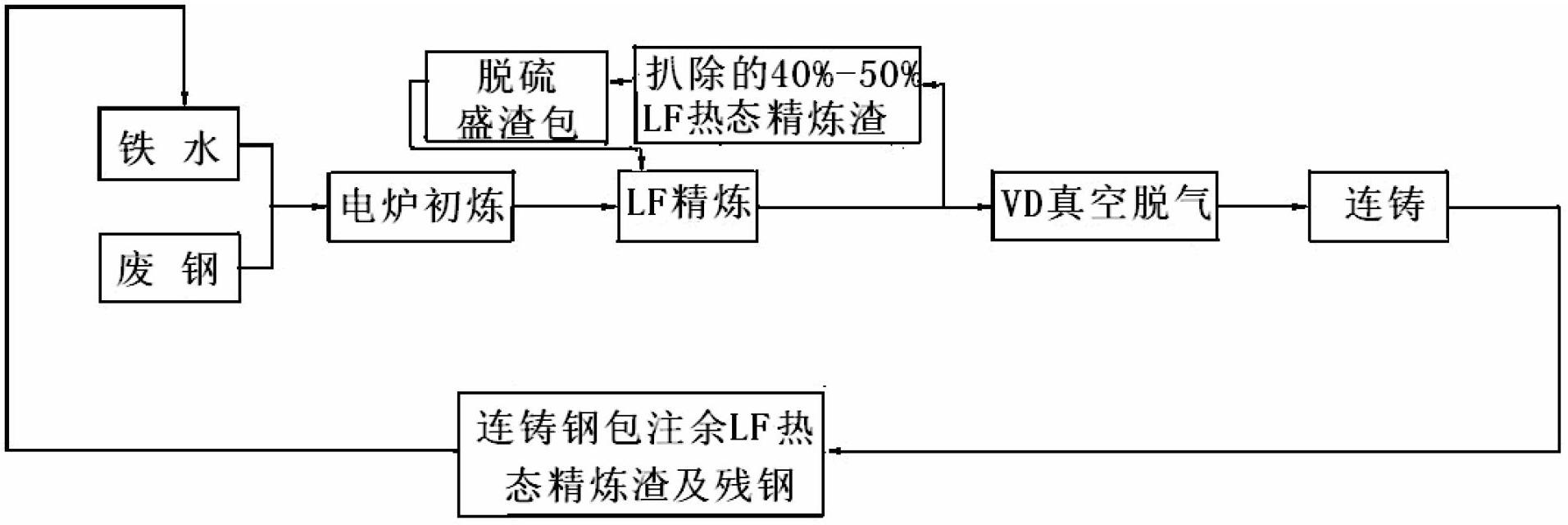

[0042] See figure 2 , smelting steel type 20CrMoA, the uncirculated furnace molten steel is refined by LF, before VD treatment, remove 40%-50% of LF hot refining slag, pour it into the desulfurization slag bag, after gasification and desulfurization, then pour Put it into the ladle that circulates one furnace to be refined by LF furnace for LF refining. After six times of recycling, new refining slag is recreated and continued to be recycled; after the continuous casting of each furnace, the ladle is injected with waste heat refining slag and remaining Residual steel is directly blended into the electric furnace ladle, and when the electric furnace is mixed with molten iron, it is added to the electric furnace to replace part of the slagging material, used for dephosphorization and desulfurization of the electric furnace, and the remaining molten steel is injected into the recycled ladle; the specific parameters are shown in Table 3. Electric furnace slagging agent lime is re...

Embodiment 3

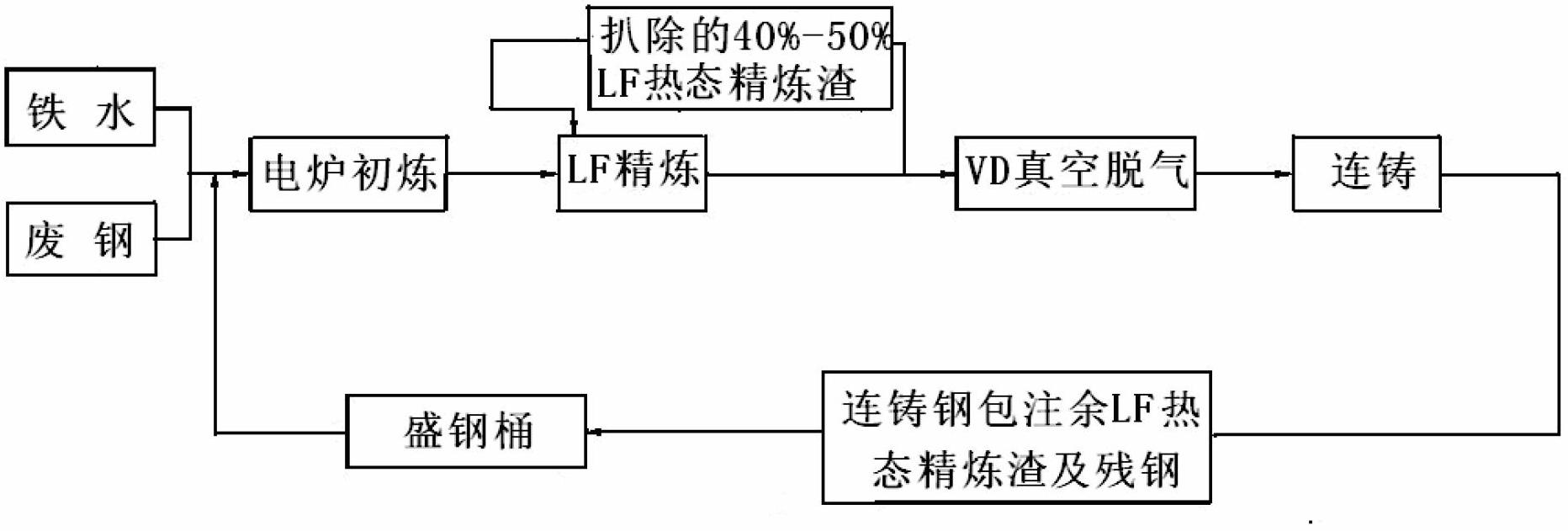

[0048] See image 3 , smelting steel type 45#, the molten steel of the uncirculated furnace is refined by LF, and before VD treatment, 40%-50% of the hot refining slag of LF is removed, and it is directly poured into the molten steel of the first circulating furnace to be refined by the LF furnace In the ladle, it is used for LF refining. After five times of recycling, new refining slag is recreated and continued to be recycled. After each continuous casting, the ladle is filled with residual heat refining slag and remaining steel and poured into a ladle for heat preservation. When molten iron is added to the electric furnace to replace part of the slagging material, it is used for dephosphorization and desulfurization in the electric furnace, and the remaining molten steel is recycled and injected into the ladle; see Table 5 for specific parameters. Electric furnace slagging agent lime is reduced by 200kg / furnace, pre-slag (slagging agent + lime) consumption is reduced by 267...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com