Superlattice phase change thin film with low density change, phase change memory and preparation method thereof

A technology of phase change memory and density change, which is applied in the direction of electrical components, etc., can solve the problems of large two-state density changes, voids, device failure, etc., and achieve the effects of improving service life, mature technology, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The first and second phase change layers can be prepared by magnetron sputtering, atomic layer deposition, molecular beam epitaxy, pulsed laser deposition, physical vapor deposition, chemical vapor deposition, thermal evaporation or electrochemical growth. any of the.

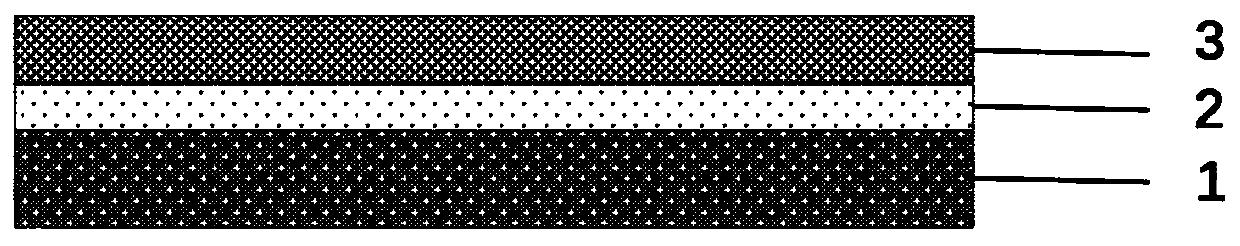

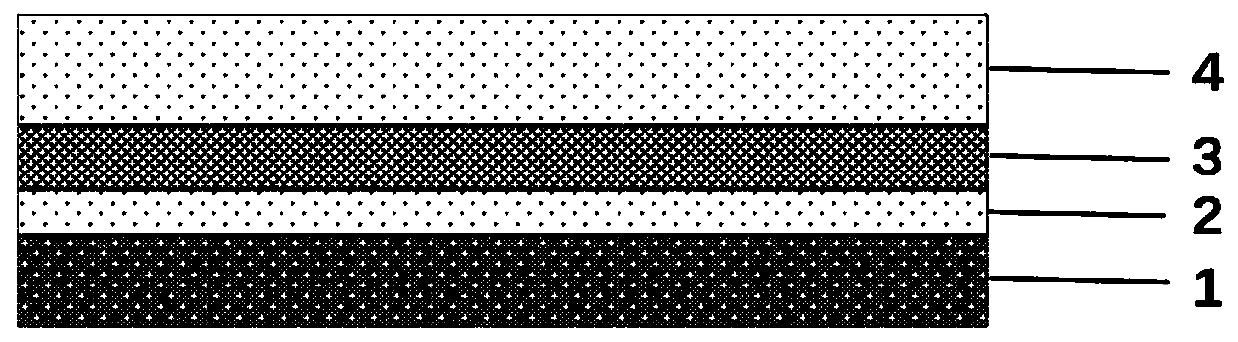

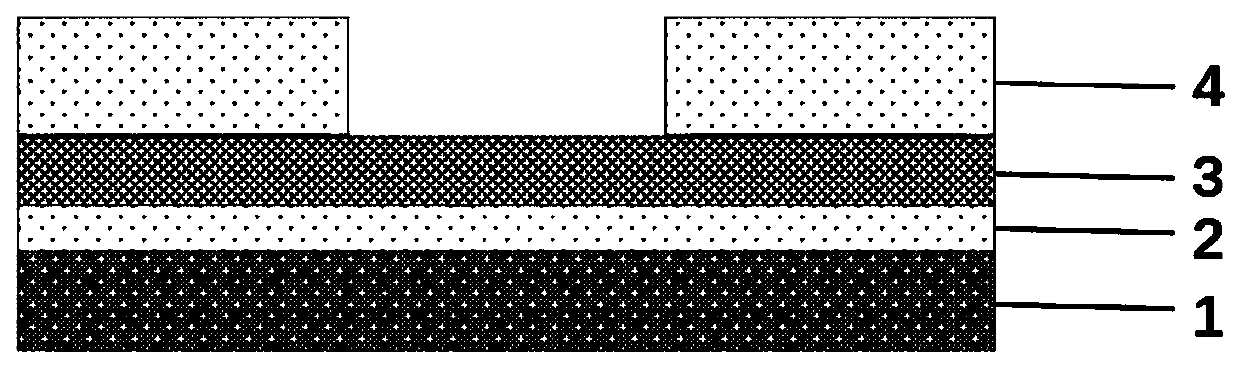

[0056] This embodiment also provides a phase-change memory, which includes the above-mentioned superlattice phase-change film, and also includes an upper electrode and a lower electrode, and the superlattice phase-change film is arranged between the upper electrode and the lower electrode, including The first and second phase change layers are stacked alternately, and the second phase change layer has an abnormal negative density change rate during the crystallization process. During the process of crystallization and amorphization, the volume change of the negative density change layer has an opposite trend compared with that of the ordinary phase change material layer. Therefore, the superlattice phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com