Superlattice phase change thin film with low density change, phase change memory and preparation method thereof

一种相变存储器、密度变化的技术,应用在电气元件等方向,能够解决两态密度变化大、空洞、器件失效等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

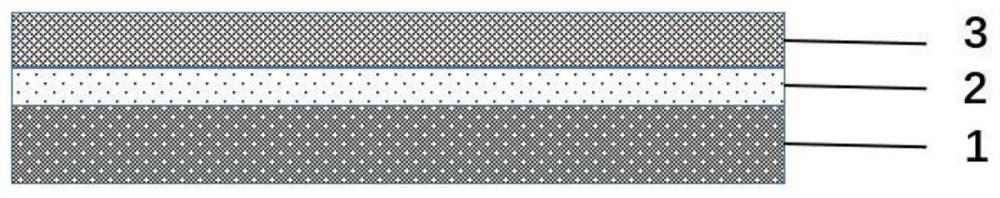

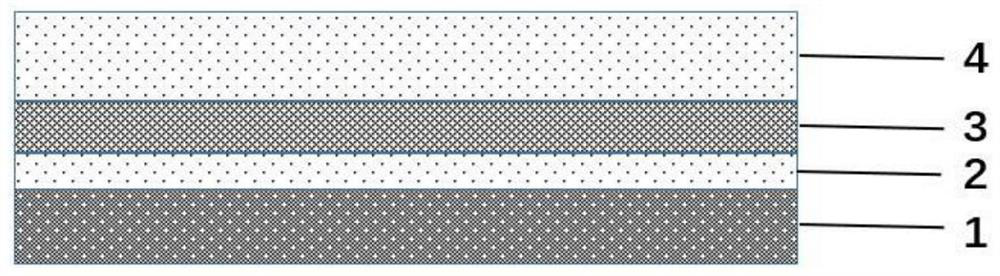

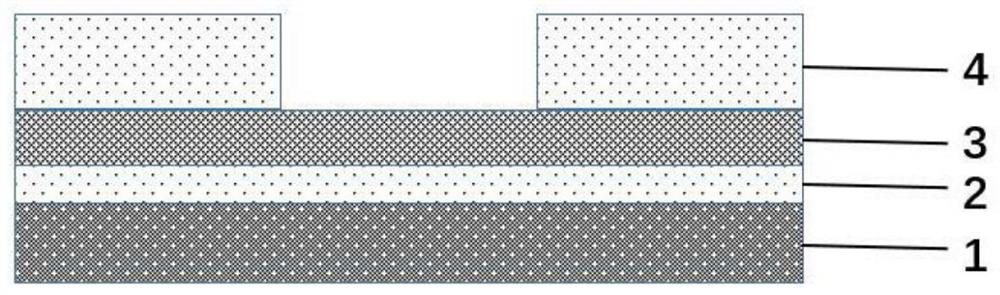

[0055] First, preparation of two phase change layer may be deposited by magnetron sputtering, atomic layer deposition method, molecular beam epitaxy, pulsed laser deposition, physical vapor deposition, chemical vapor deposition, thermal evaporation or electrochemical growth process either in.

[0056] The present embodiment further provides a phase change memory, phase change memory including the above-described superlattice phase-change film, further comprising upper and lower electrodes, a superlattice phase-change film disposed on the electrode, between the lower electrode, comprising alternating the first and second phase change layer stack, and the second phase change layer having a negative anomalous density change rate in the crystallization process. The density of the negative change layer during crystallization and amorphization, the volume change compared to the ordinary phase change material layer having an opposite tendency. Thus both the superlattices are stacked to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com