Metal electrodeposition device

A metal electrodeposition and electrodeposition technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of low hardness of the deposition layer, low electrodeposition speed, poor compactness, etc., to improve the deposition speed, the reaction speed, the structure dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

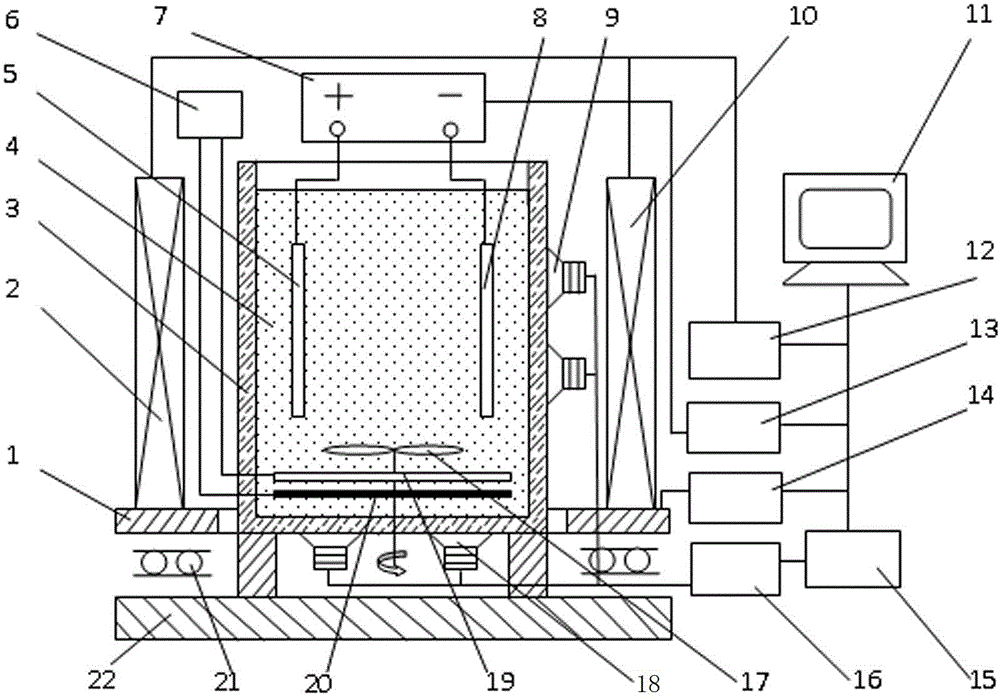

[0015] In an embodiment of the metal electrodeposition method provided by the present invention, during the metal electrodeposition process, the cathode and the anode are vertically placed in the electrolyte, and then the negative electrode of the power supply is connected to the cathode, and the positive electrode of the power supply is connected to the anode. During the deposition process, an electric field is formed in the electrolyte by the anode and the cathode, ultrasonic waves parallel or perpendicular to the direction of the electric field are applied to the electrolyte, and a magnetic field parallel or perpendicular to the direction of the electric field is applied to the electrolyte, cathode, and anode to cooperate with the ultrasonic waves At the same time, the electrolyte is mechanically stirred, and the temperature of the electrolyte is kept stable by the heating system. In the process of electrodepositing metal materials on the cathode, the direction, frequency and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com