Heating system for epoxy asphalt steel bridge deck pavement and pavement method

A heating system, epoxy asphalt technology, applied in the direction of roads, road repair, roads, etc., to achieve the effect of speeding up the paving speed and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Preparation of heating systems for epoxy asphalt steel bridge deck pavement:

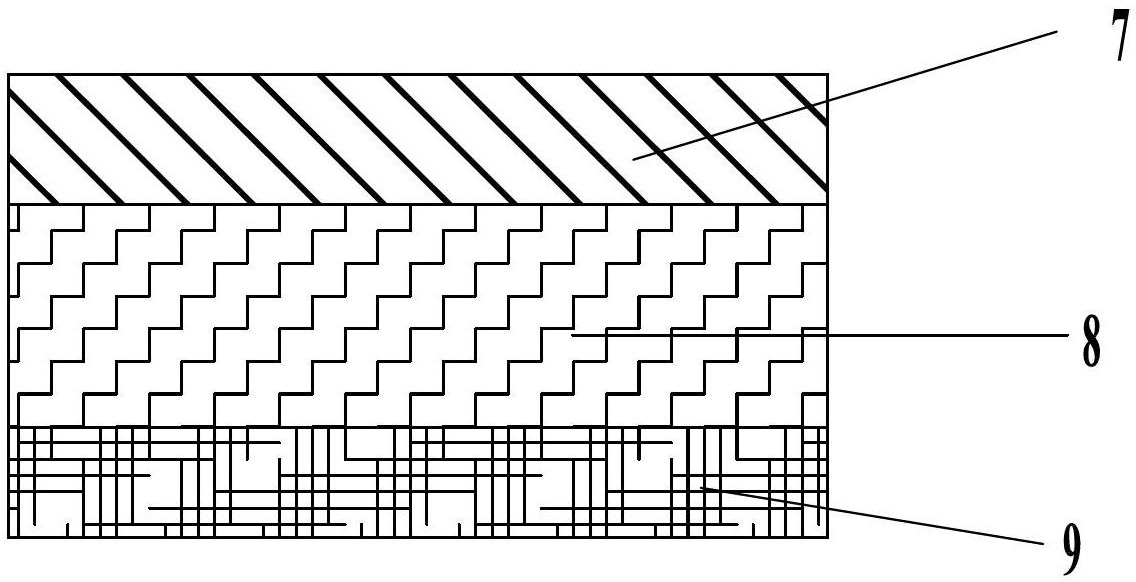

[0069] (1) Preparation of magnetic silica gel heating sheet: the main body of the magnetic silica gel heating sheet is a silica gel heating sheet, magnetic powder is glued on one side of the silica gel heating sheet, and insulation cotton is glued on the other side. structured as image 3 shown.

[0070] (2) Preparation of a magnetic silica gel heating system: each piece of the magnetic silica gel heating sheet is connected in series with a thermocouple temperature control switch to form a temperature-controllable magnetic silica gel heating sheet. The obtained multiple temperature-controllable magnetic silica gel heating sheets are connected in parallel to the control cabinet to form a magnetic silica gel heating system.

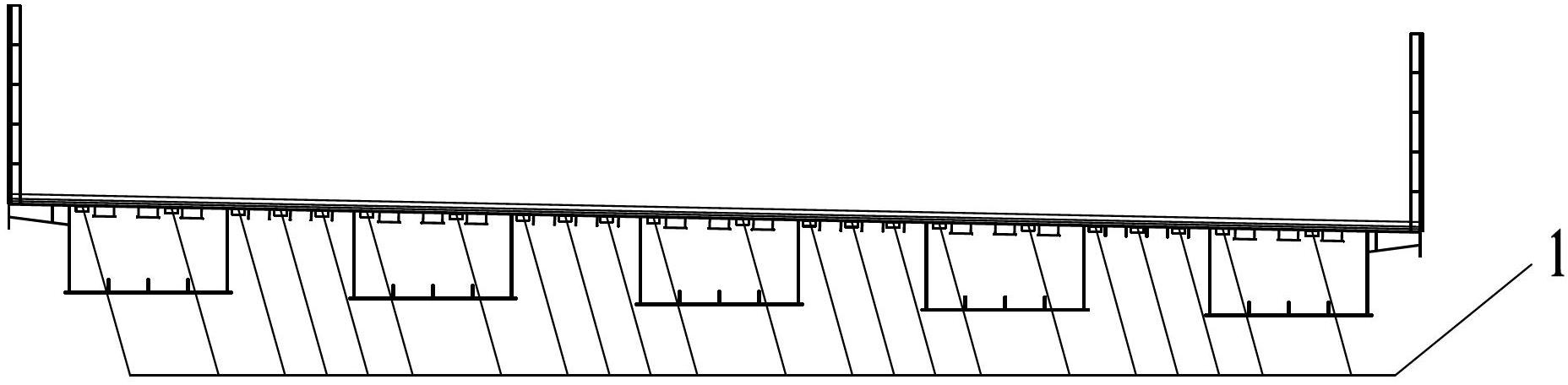

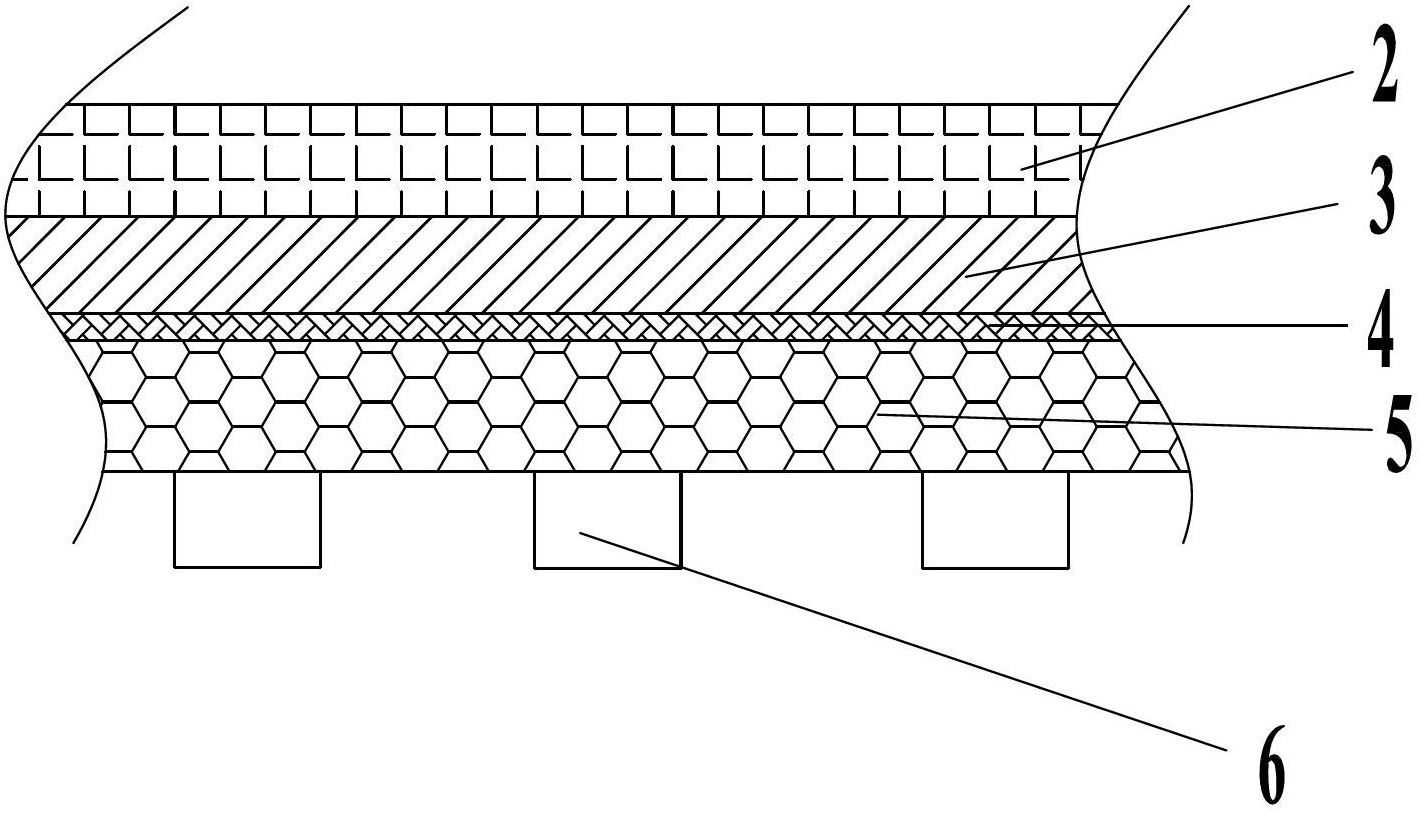

[0071] (3) Prepare a temperature-controllable steel bridge deck: fix the obtained magnetic silica gel heating system on the opposite side of the steel bridge paving surf...

Embodiment 2

[0075] Preparation of heating systems for epoxy asphalt steel bridge deck pavement:

[0076] (1) Preparation of a magnetic polyimide film heater: the magnetic polyimide film heater, the main body is a polyimide film heater, the polyimide film heater is embedded in the silica gel layer, and the silica gel layer At the same time, a magnet is embedded in it, and thermal insulation cotton is glued on one side of the polyimide film heating sheet.

[0077] (2) Preparation of a magnetic polyimide film heating system: each magnetic polyimide film heating plate is connected in series with a temperature control switch to form a temperature-controllable magnetic polyimide film heating plate. The obtained multiple temperature-controllable magnetic polyimide film heating sheets are connected in parallel to the control cabinet to form a magnetic polyimide film heating system.

[0078] (3) Prepare a temperature-controllable steel bridge deck: fix the obtained magnetic polyimide film heating...

Embodiment 3

[0082] A paving method for epoxy asphalt steel bridge deck, comprising (1) spraying binder; (2) mixing epoxy asphalt mixture (3) transporting epoxy asphalt mixture; (4) paving and rolling; 5) Insulation and maintenance steps. The temperature control of the pavement process is as follows through the epoxy asphalt steel bridge deck pavement:

[0083] (1) The temperature of the bridge deck when spraying the binder is 20-25°C;

[0084] (2) Mixing process of epoxy asphalt mixture: 1) Heat material A to 87±3°C; 2) Heat material B to 150±3°C; 3) When using, mix the two at 110- 130°C;

[0085](3) Transportation process of epoxy asphalt mixture: keep the temperature of the compartment of the transport vehicle at 120±3°C;

[0086] (4) Paving and rolling process: when paving, the overall temperature of the steel bridge is 45-85°C; during rolling: the temperature at the end of the initial pressing is ≥82°C, and the temperature at the end of the final pressing is ≥65°C;

[0087] (5) He...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Marshall stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com