A kind of bridge deck pavement waterproof bonding layer and construction method thereof

A technology for waterproof bonding layer and bridge deck paving, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of easy rolling off, poor durability, poor waterproof effect, etc., achieve fast temperature loss, and ensure initial density. and smoothness, the effect of speeding up the paving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

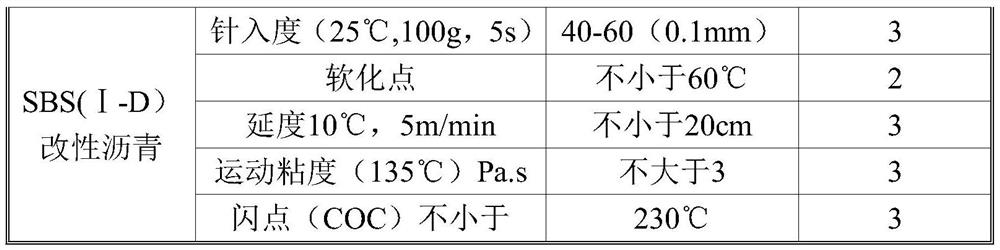

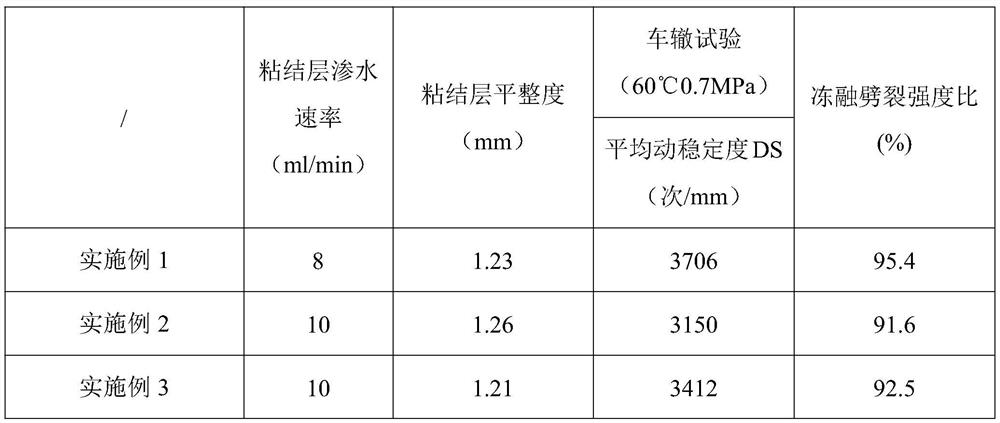

Embodiment 1

[0063] A bridge section is a large bridge across a river and a lake. It is located in a lake basin, and has a large amount of rainfall and water mist all year round. In order to improve the waterproof ability of the bridge pavement structure, the driving comfort and the service life of the pavement, a new bridge pavement waterproof bonding layer and its construction method are provided.

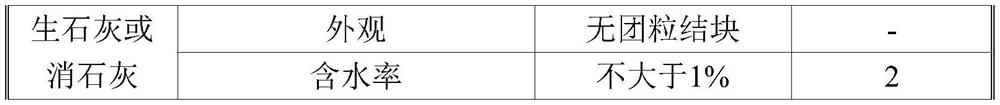

[0064] The waterproof adhesive layer is mainly composed of the following raw materials,

[0065] 7 parts of SBS modified asphalt; 25 parts of basalt gravel with a particle size gradation of 3-6mm; 72 parts of basalt gravel with a particle size gradation of 0-3mm; 1.3 parts of quicklime powder; 1.7 parts of mineral powder.

[0066] The waterproof adhesive layer is constructed by the following method.

[0067] Check the lower bearing layer before construction, clean up pollutants and garbage in time, fill expansion joints and prevent pollution, complete mechanical equipment repair and maintena...

Embodiment 2

[0079] Waterproof adhesive layer raw material

[0080] 6.8 parts of SBS modified asphalt; 23 parts of basalt gravel with particle size gradation of 3-6mm; 74 parts of basalt gravel with particle size gradation of 0-3mm; 1.0 part of quicklime powder; 2.0 parts of mineral powder.

[0081] Construction method

[0082] Step 1. Clean up the bridge deck to be laid and leveled; mix the raw materials of the waterproof adhesive layer according to the mix ratio. The mixing time is 30s, and the mixing temperature is controlled at 170°C;

[0083] Step 2. Use a high-power full-width paver to spread the mixture to the layer to be paved. In order to ensure the flatness of the paved surface and construction efficiency, a high-power full-width paver is used to pave the upper layer of asphalt concrete. During the construction process, full braking functions such as speed, material delivery, material level, frequency, amplitude, anti-dropping at stop, and anti-lifting at start are guarantee...

Embodiment 3

[0089] Waterproof adhesive layer raw material

[0090] 7.2 parts of SBS modified asphalt; 27 parts of basalt gravel with particle size gradation of 3-6mm; 70 parts of basalt gravel with particle size gradation of 0-3mm; 1.2 parts of quicklime powder; 2.3 parts of mineral powder.

[0091] Construction method

[0092] Step 1. Clean up the bridge deck to be laid and leveled; mix the raw materials of the waterproof adhesive layer according to the mix ratio. The mixing time is 50s, and the mixing temperature is controlled at 180°C;

[0093] Step 2. Use a high-power full-width paver to spread the mixture to the layer to be paved. In order to ensure the flatness of the paved surface and construction efficiency, a high-power full-width paver is used to pave the upper layer of asphalt concrete. During the construction process, full braking functions such as speed, material delivery, material level, frequency, amplitude, anti-dropping at stop, and anti-lifting at start are guarante...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com