High-strength leakproof packing structure of gob-side entry retaining roadside and construction method thereof

A leak-proof and high-strength technology, which is applied in the fields of backfill, earthwork drilling, safety devices, etc., to achieve the effect of simple structure, prevention of air leakage in roadway retention, and enhancement of airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific construction mode of the present invention is described below with reference to accompanying drawing.

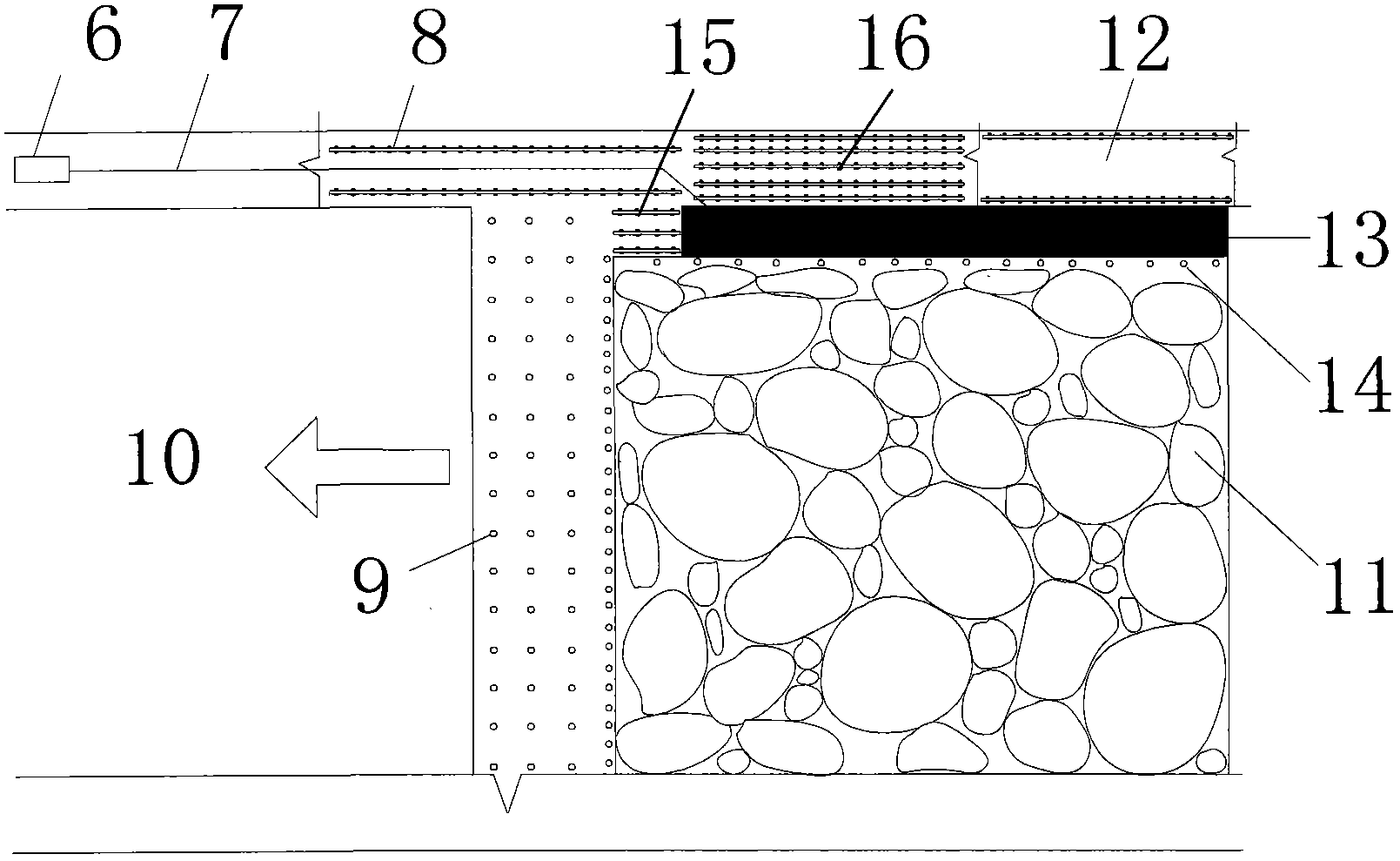

[0021] The first step: after the excavation of the underground roadway, anchor, cable, net, belt support and single hydraulic prop 9 support on the working face are carried out, and the working face 10 is arranged at the same time. After the underground working face 10 is arranged, the normal coal cutting and column return start A goaf 11 is formed.

[0022] Step 2: Carry out advance support 8 plus hinged top beam support in the entry retaining 12, and then use wooden pillars 14 for support and reinforcement within the filling width of the retaining entry side. With the advancement of the working face, increase the advance support at 8 The single hydraulic prop 9 is strengthened as a hysteresis support 16, and the hysteresis support 16 and the wooden prop 14 jointly bear the initial pressure of the top plate before the filling material condenses.

[0023...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com