Automatic transmission hub motor driving mechanism for electric vehicle

An automatic variable speed, wheel hub motor technology, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of complex manufacturing process, energy waste, and reduced battery life, and meet the needs of climbing and extreme speed. The effect of reducing production costs and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

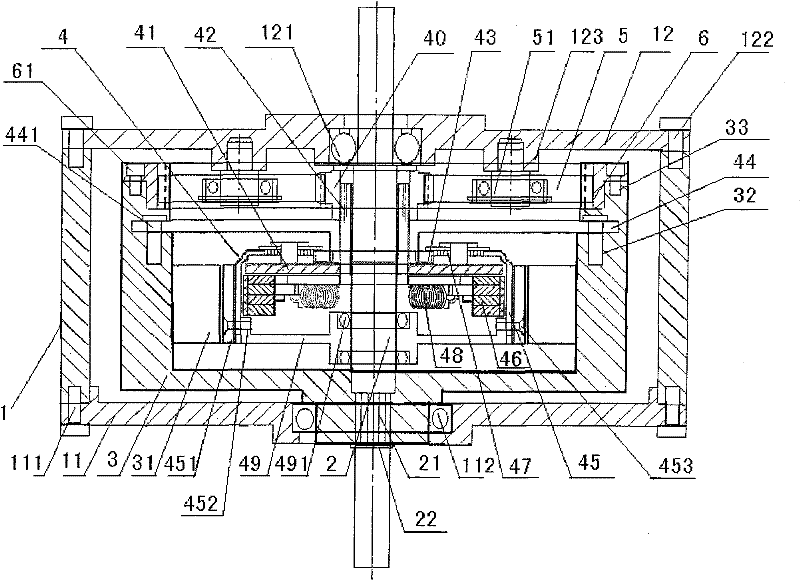

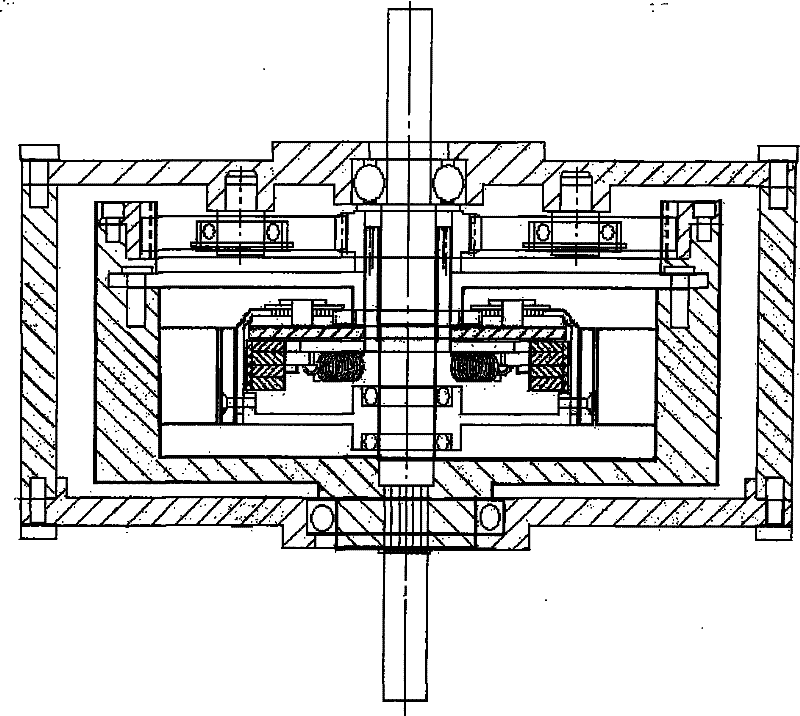

[0008] The invention discloses an automatic variable speed hub motor transmission mechanism for an electric vehicle, such as figure 1 As shown, there are wheel hub 1, upper and lower end caps, motor, automatic transmission 4, planetary gear reduction mechanism, main shaft 2 and other components. It is characterized in that the automatic transmission 4 has a sun gear fixed plate 44, a driving disc 41, a casing 45, a positioning plate 49, a planetary gear reducer and the like. There is a magnetic steel 451 outside the casing 45, and a stator 31 outside the magnetic steel 451. The stator 31 is fixed on the motor 3 casing, the casing 45 is connected to the positioning plate 49 along the mouth, and the main shaft 2 is fixedly connected to the motor casing 3 through the center of the automatic transmission 4. The bearing hole of the end cover extends to the outside and is fixedly connected with the frame, the inner hole of the motor housing 3 and the lower end cover 11 bearing 112 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com