Process method for connecting metal-extrusion type pipe fitting with high infiltration prevention

A technology of metal extrusion and process method, applied in the direction of non-detachable pipe connections, pipes/pipe joints/fittings, passing components, etc., can solve problems such as affecting sealing, seasonal leakage, insufficient reliability, etc., and solve potential safety hazards , Strong anti-destructive ability, reliable and strong connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment the present invention is further described.

[0019] A high impermeability metal extrusion type pipe fitting connection process method, comprising the following steps:

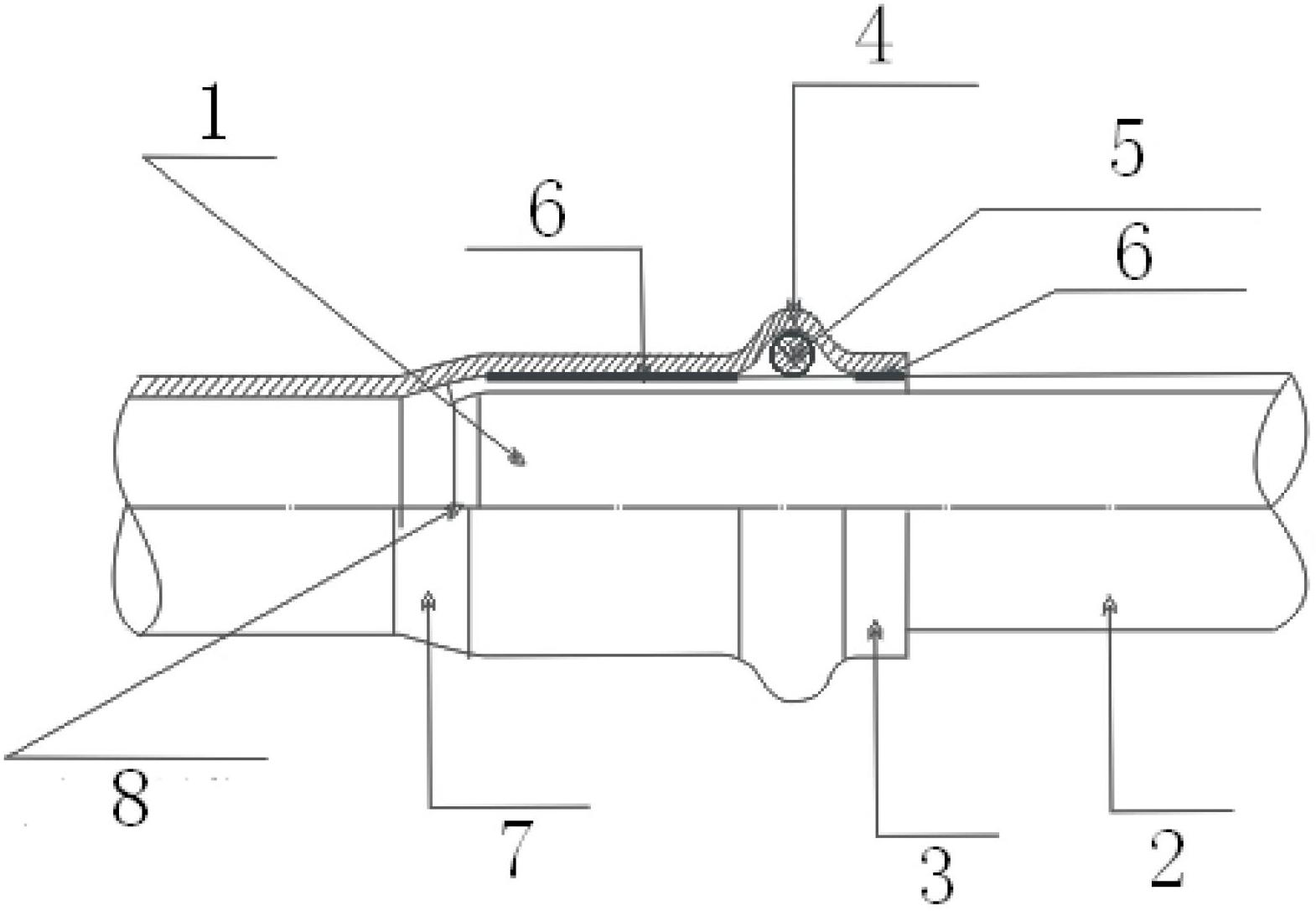

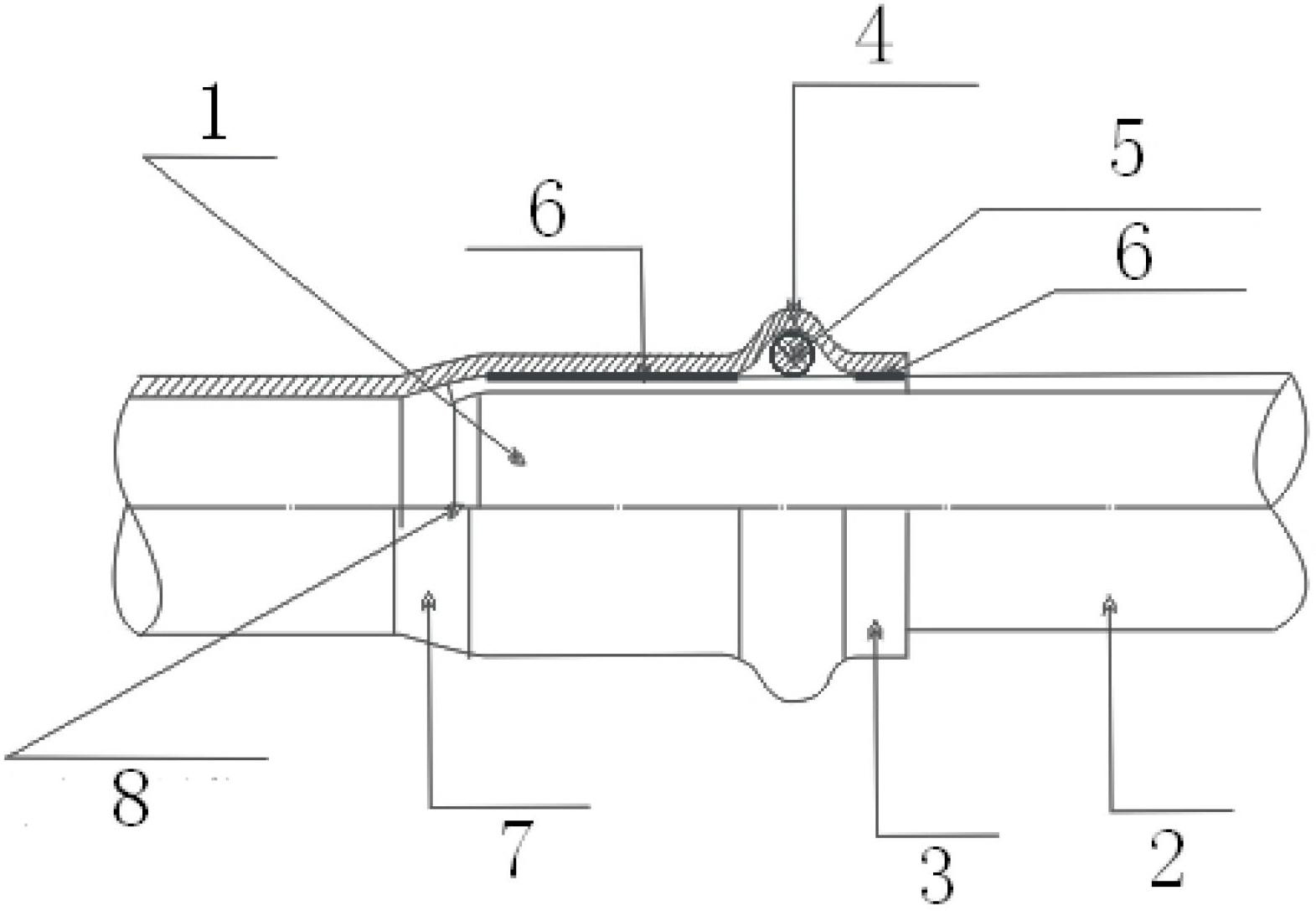

[0020] A. Prepare metal extruded socket-type pipe fittings 1. A protruding circumferential protruding ring 4 is provided at the socket 3 to form an inner groove, and an elastic seal 5 is placed in the groove, such as figure 1 shown;

[0021] B. Apply the prepared adhesive sealant 6 evenly on the peripheral surface of the inner cylinder of the socket pipe fitting interface with an applicator or a brush, such as figure 1 shown;

[0022] C. Insert the pipe 2 with the mouth cleaned well into the pipe socket pipe fitting 1, the insertion depth reaches the socket limit junction 7, and the gap between the outer wall of the pipe and the inner wall of the pipe fitting socket is 0.1-0.3mm, such as figure 1 shown;

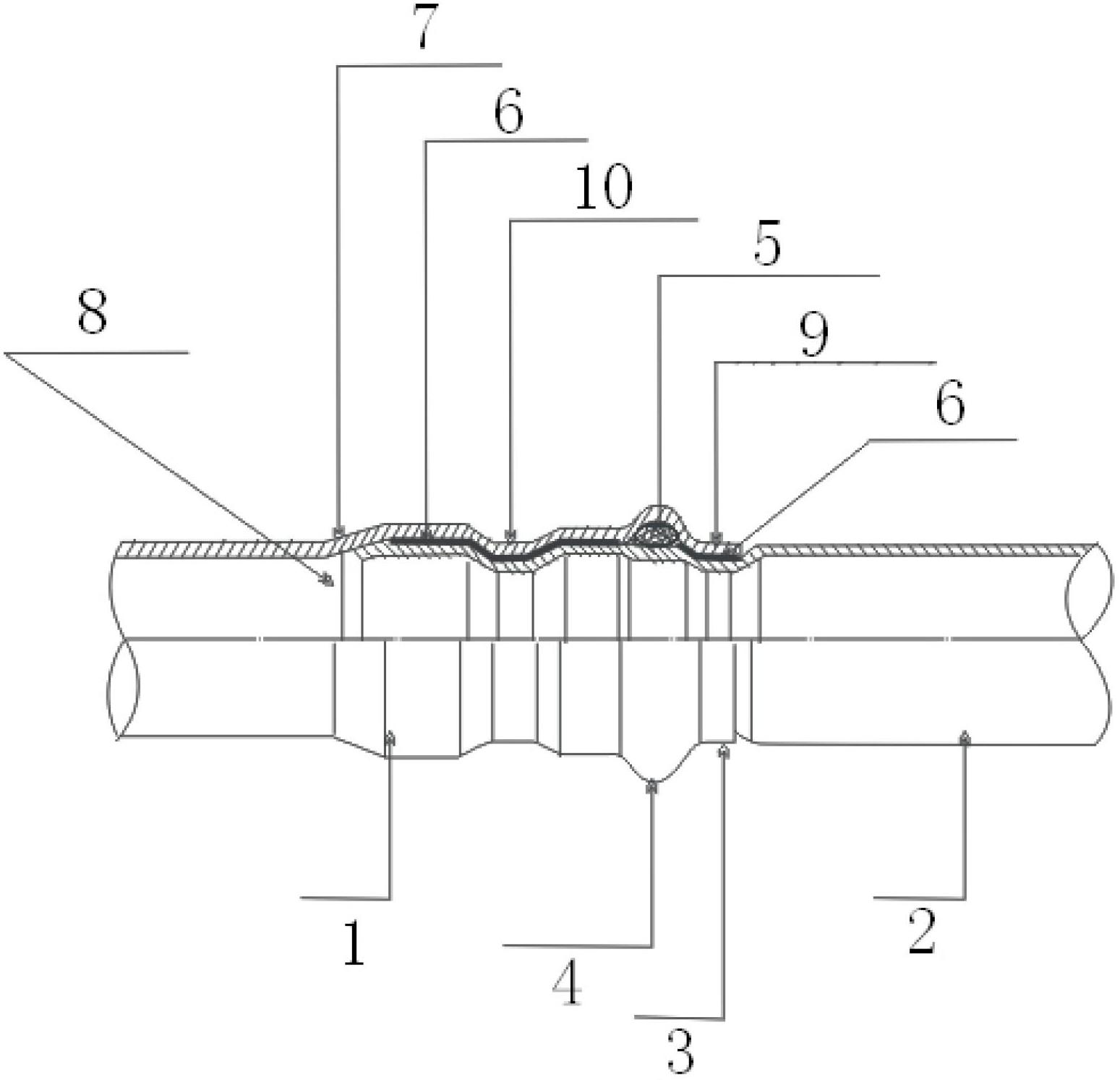

[0023] D. Use the interface pressing tool to install the j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com