Quickly assembled hanging part with low flow resistance for heat exchange tube

A heat exchange tube, low flow resistance technology, applied in the direction of cleaning heat transfer devices, heat transfer modification, heat exchange equipment, etc., can solve the problems of large inlet pressure loss of heat exchange tubes, increased pipeline transportation resistance, blocked pipelines, etc. Achieve the effect of facilitating quick installation, ensuring stability and reducing resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

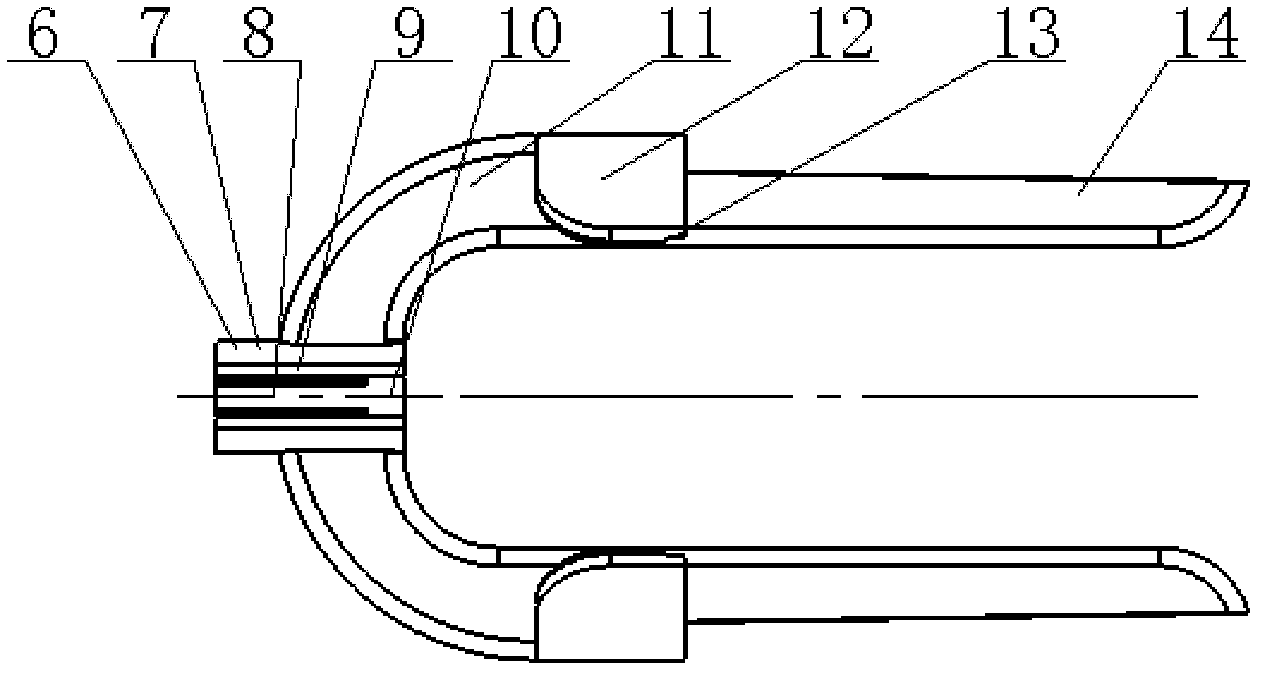

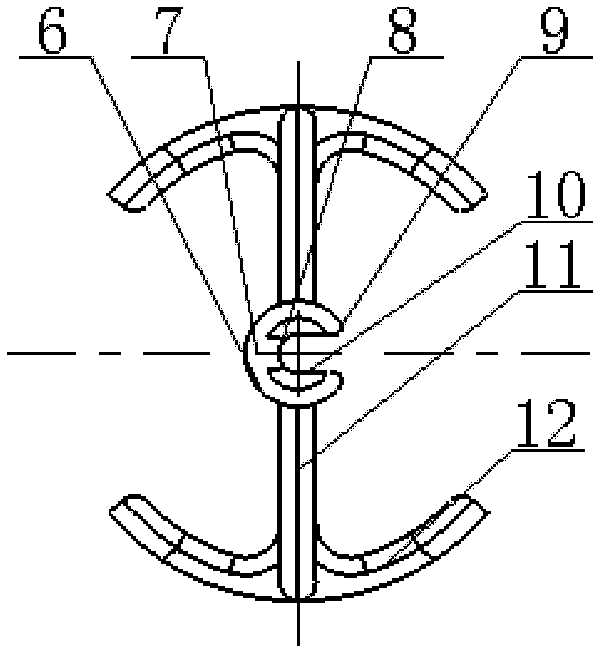

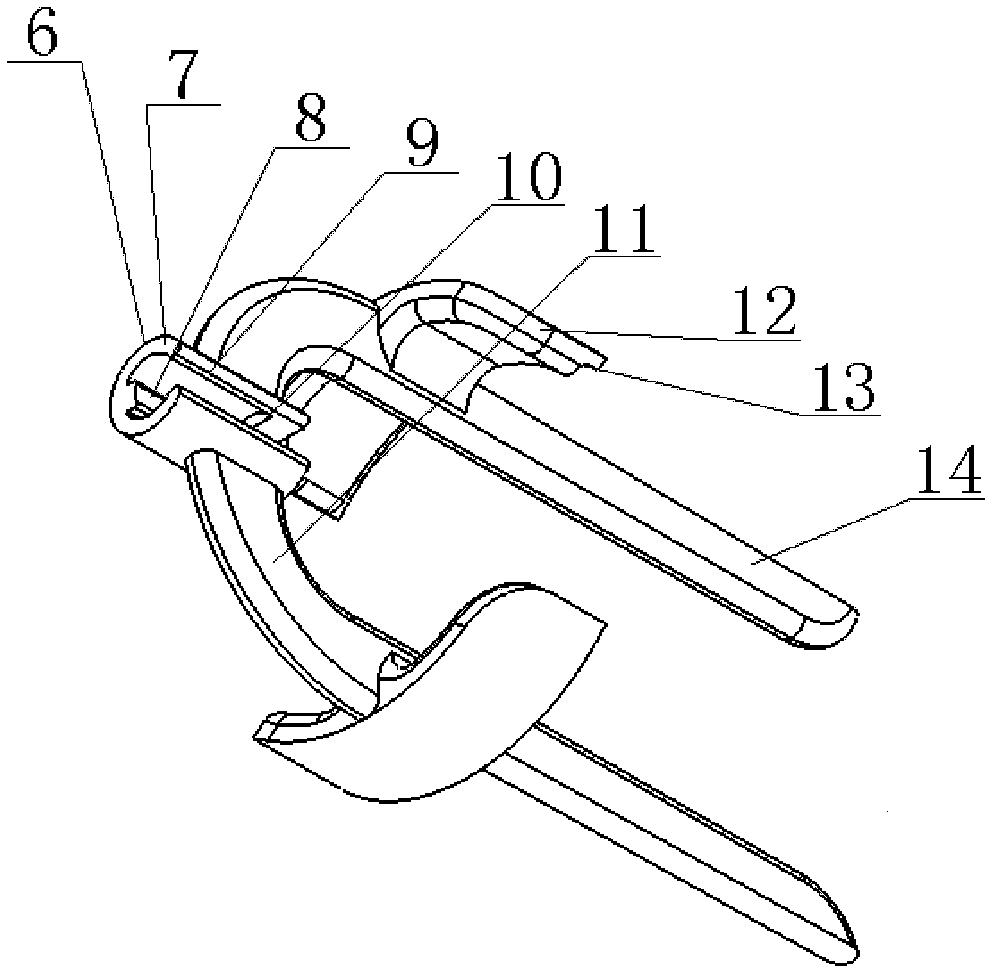

[0021] Such as Figure 6 and Figure 7 As shown, an implementation example of a low-flow-resistance quick-installation hanger for heat exchange tubes involved in the present invention includes a support shaft 1, a stopper 2, a sleeve 3, a hanger body 6, and a rotor 15. The sleeve The tube 3 and the pendant body 6 are mounted on the support shaft 1, and several rotors 15 are mounted on the support shaft 1, wherein the casing 3 and the pendant body 6 together form a low-flow-resistance quick-installation pendant for the heat exchange tube, and the pendant body 6 includes a hollow shaft 7, a connecting rod 11, a support platform 12 and an extension end 14, and the left end of the casing 3 is equipped with a stopper 2.

[0022] Such as Figure 1 to Figure 8 , figure 1 It is the front view of the low-flow-resistance quick-installation pendant body of the heat exchange tube, figure 2 for figure 1 left view of image 3 yes figure 1 3D view, Figure 4 is the front view of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com