Tobacco shred width measurement method based on image processing

A technology of width measurement and image processing, which is applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of high labor intensity, large quantity of shredded tobacco, and irregular shape, so as to improve the measurement speed, ensure the measurement accuracy and improve the efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the technical solution of the present invention, a further detailed description will be made below in conjunction with the accompanying drawings.

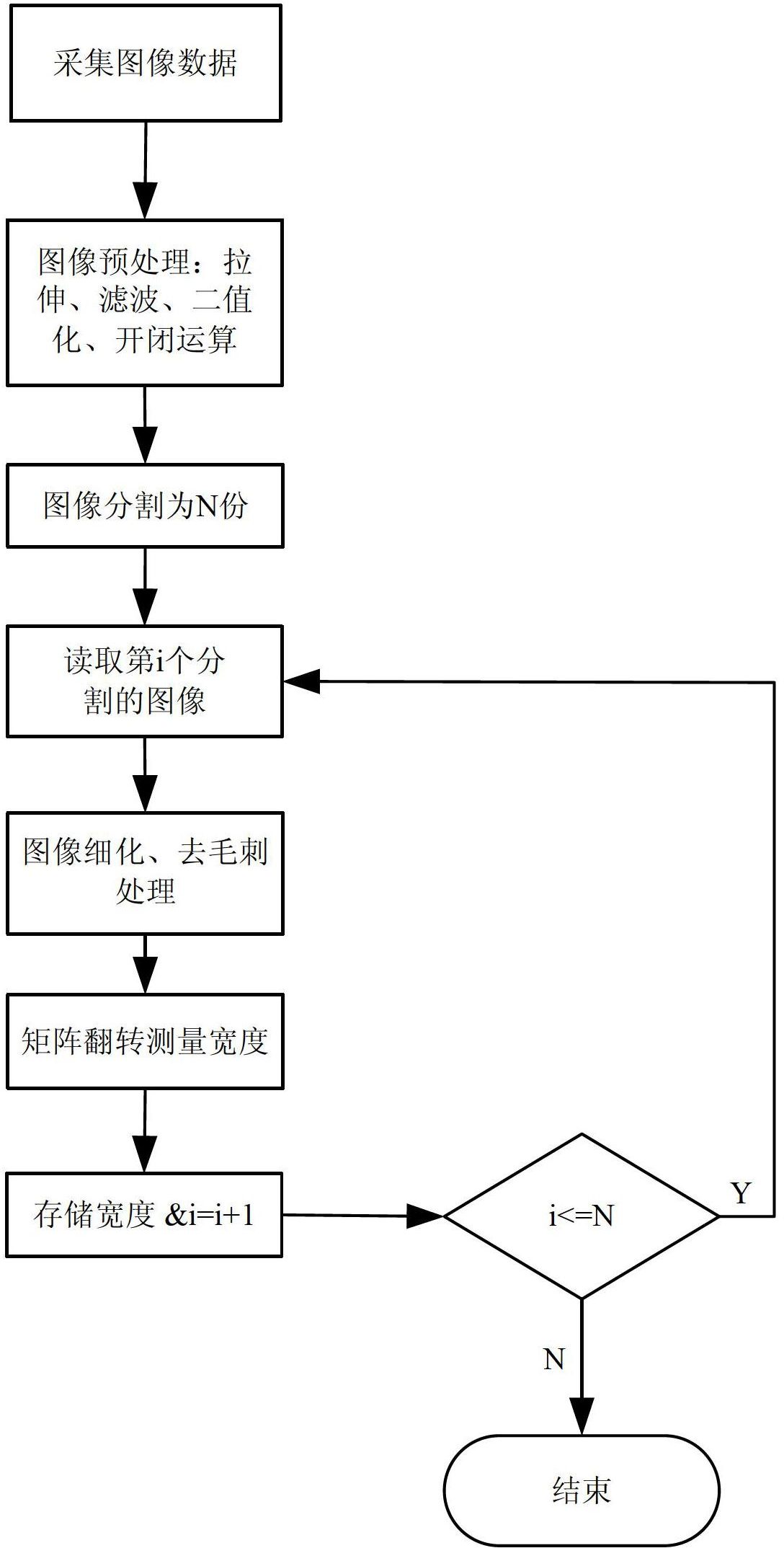

[0026] (1) Figure (1) is a flowchart involved in the present invention. The image acquisition work is realized through linear array CCD scanning. The parameters of the linear array CCD are that the pixel size is 4 μm, and the number of pixel arrays is 10550. The linear array CCD scans the cut tobacco samples placed on the stage at a uniform speed through a motor drive. And the collected images are transferred to PC via USB data cable.

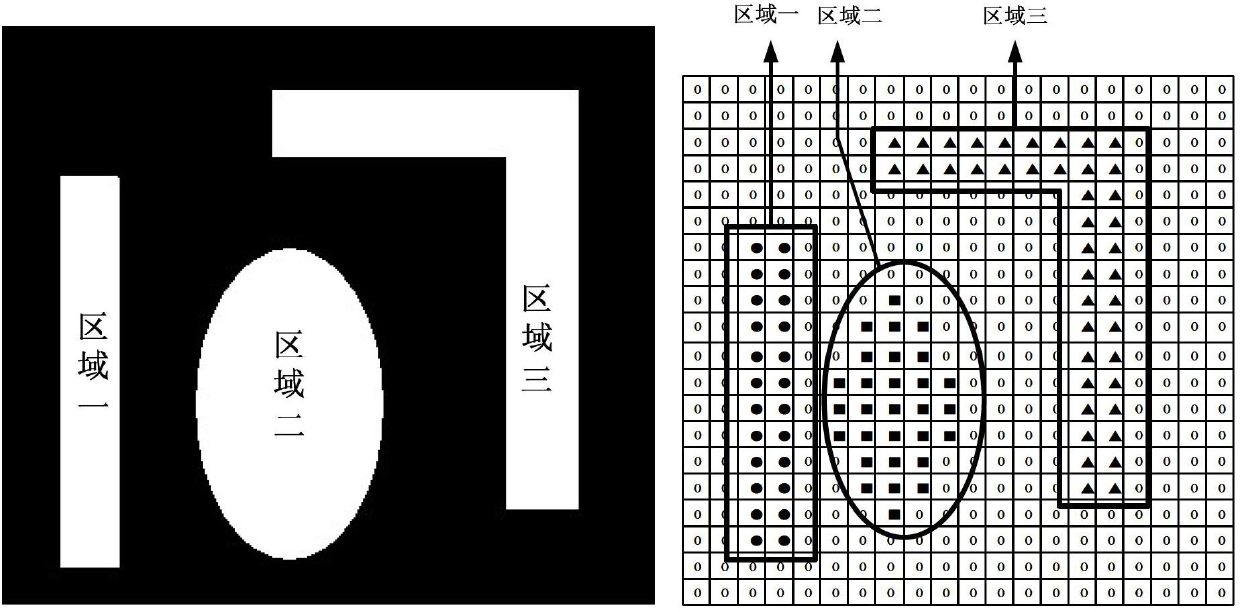

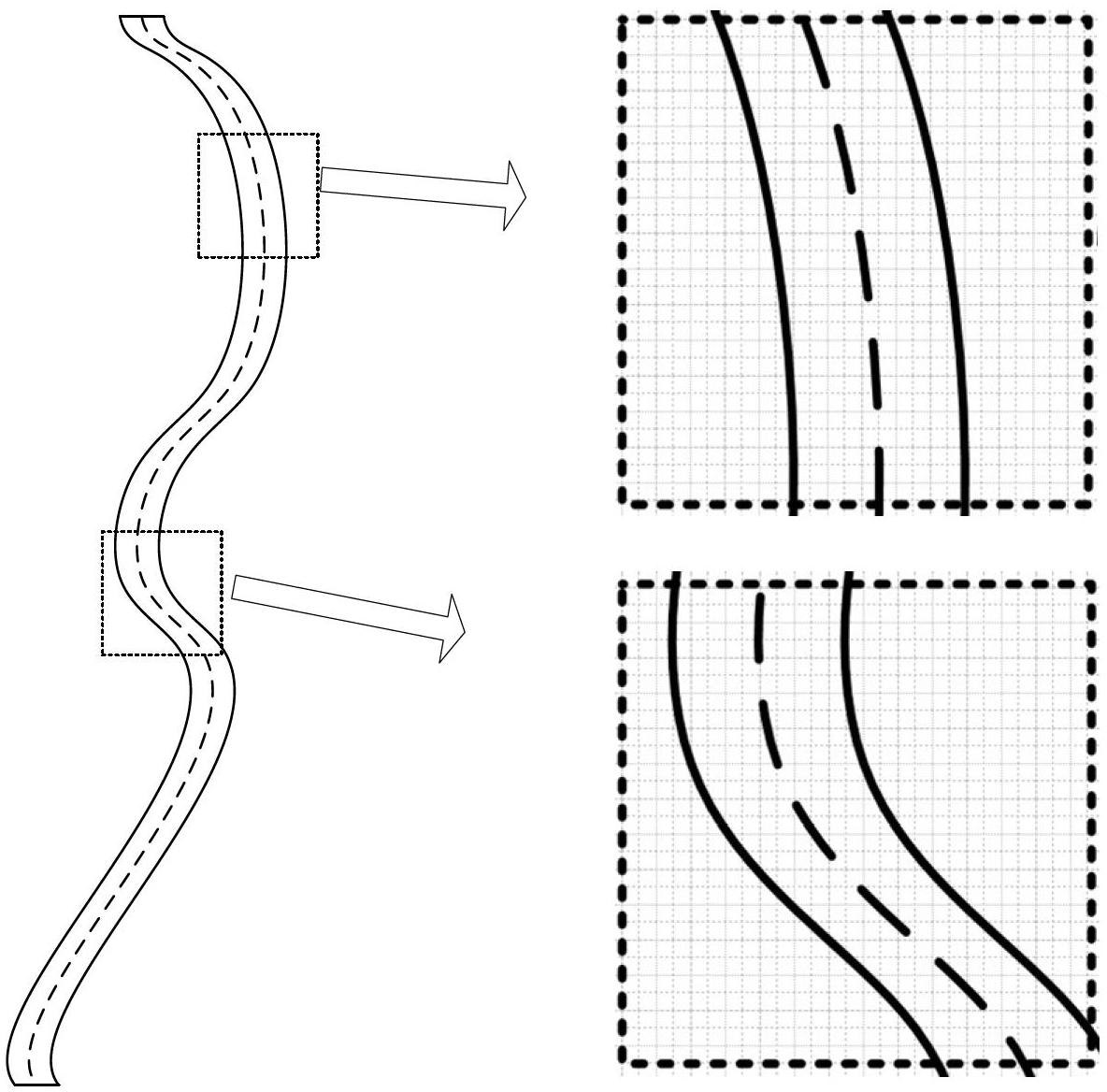

[0027] (2) Image preprocessing: The collected image is a grayscale image with an order of 256. Firstly, the grayscale is stretched to increase the contrast of the grayscale value; then the median filter is used to smooth the grayscale image, and after filtering Take a global threshold to binarize the grayscale image. After the processing, the pixel value of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com