Piston type gas-liquid dual-purpose micro-flow standard device

A flow standard device, piston-type technology, applied in measuring devices, testing/calibration devices, liquid/fluid solid measurement, etc., can solve the problems of low accuracy and difficulty in automating the verification of micro flowmeters, and achieve accurate flow regulation and improve The effect of verification accuracy, small structure and simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

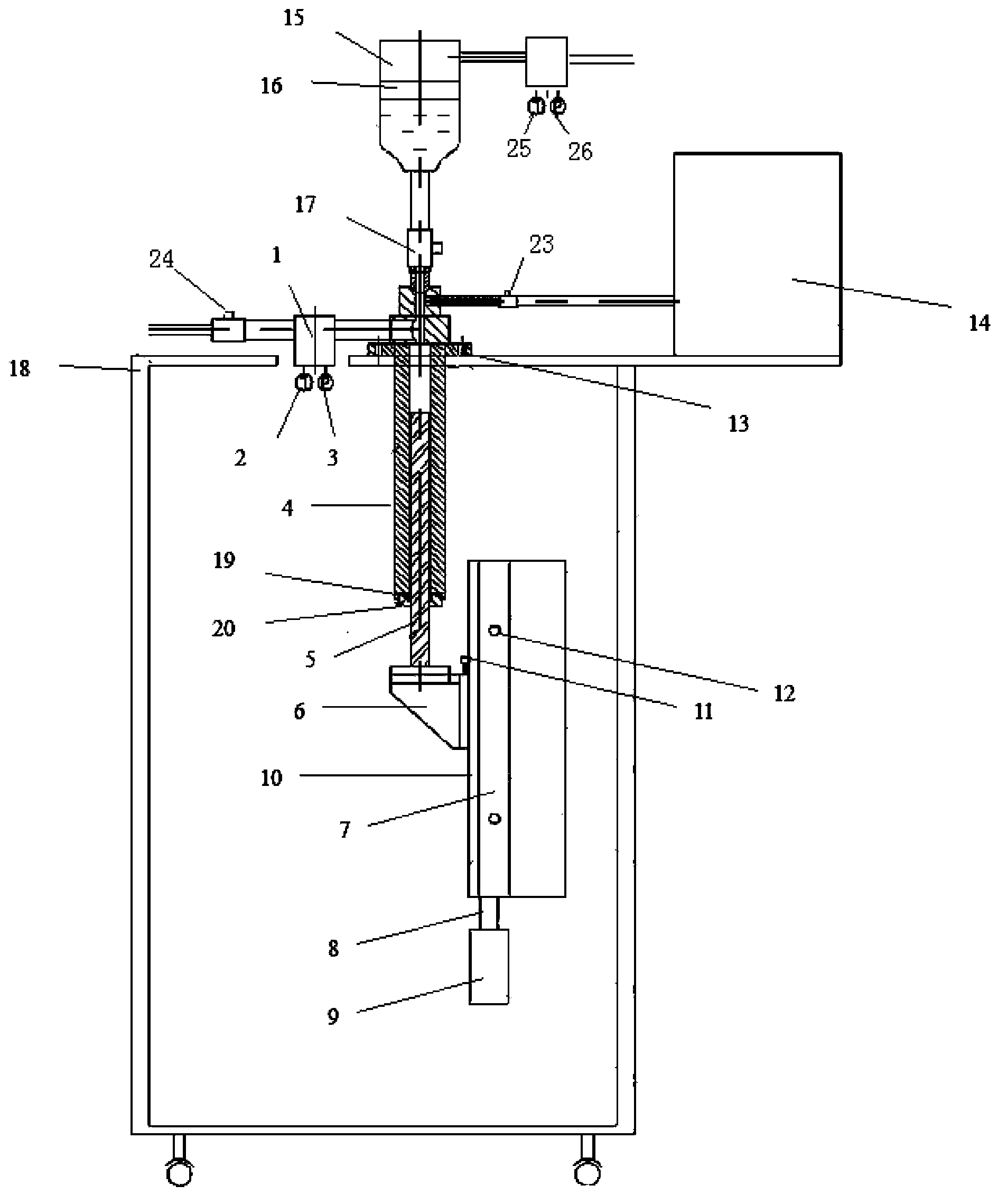

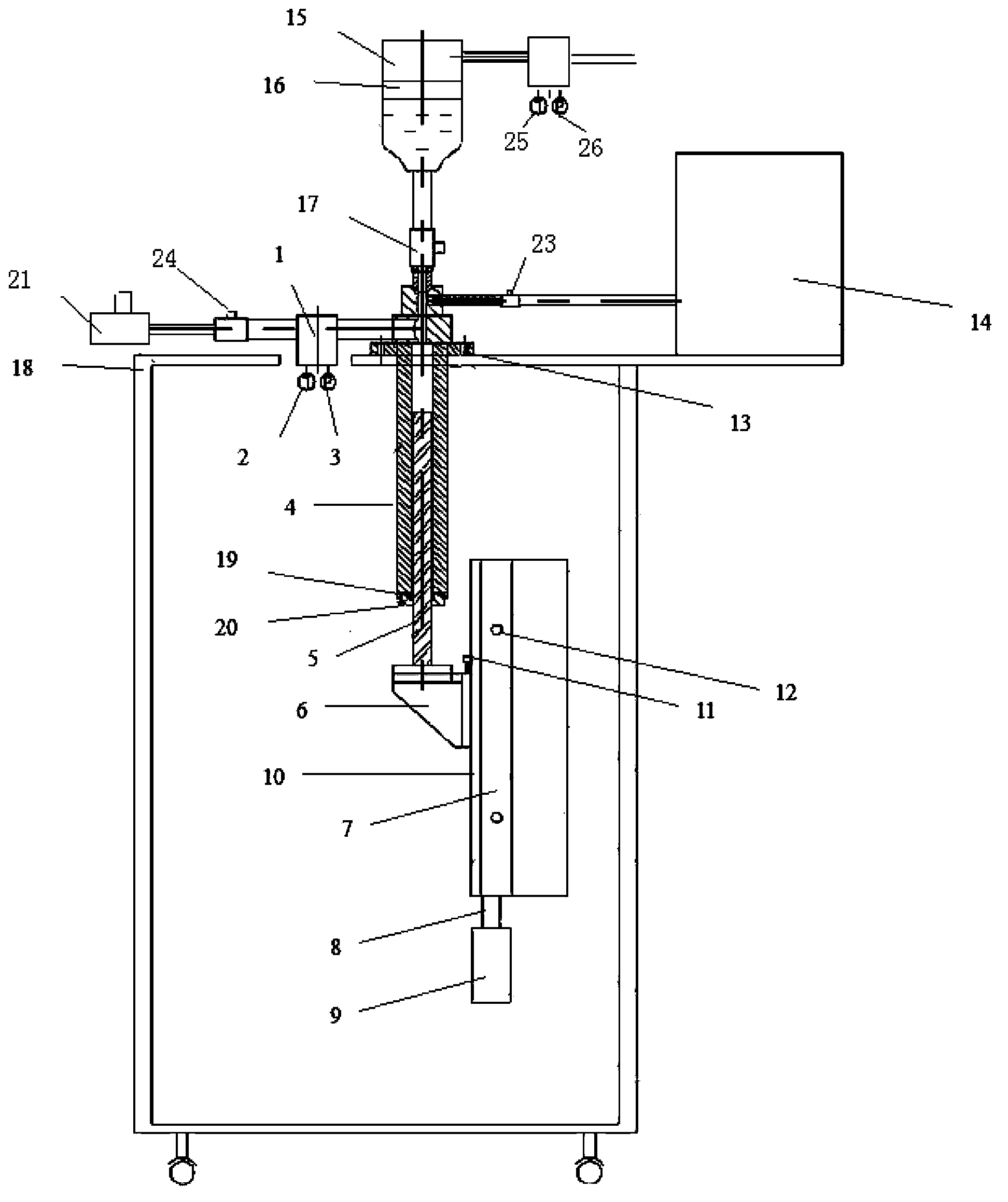

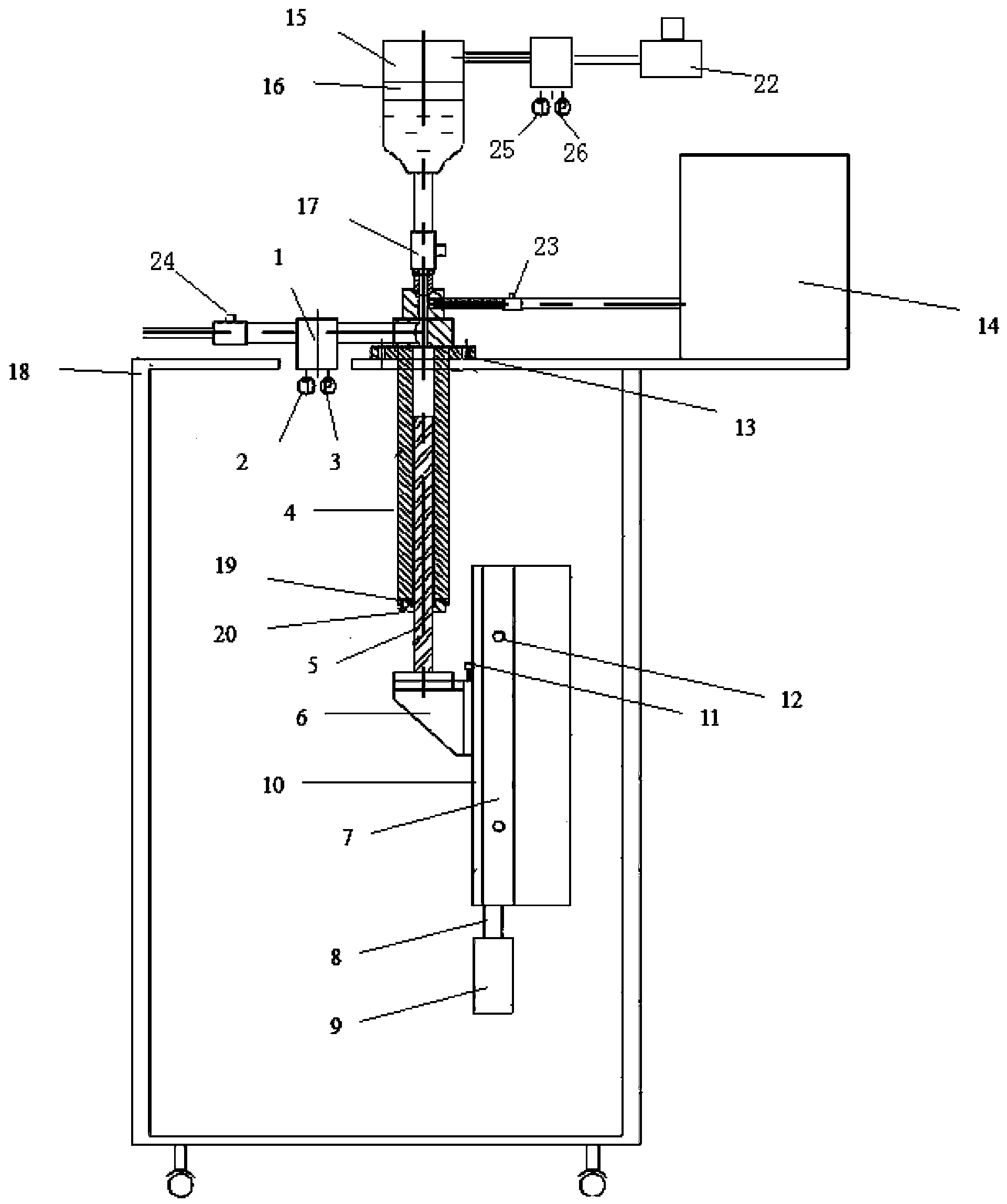

[0024] Such as figure 1 As shown, a piston-type gas-liquid dual-purpose micro-flow standard device includes a vertically inverted piston cylinder 4, the piston cylinder 4 is connected to the upper piston cylinder cover 13, and the piston cylinder 4 or the piston cylinder cover 13 is fixed On a load-bearing bracket 18, the piston cylinder head 13 includes a cross four-way interface, one of which in the horizontal direction of the cross four-way interface is connected to the water tank through the water inlet pipeline solenoid valve 23, and the other interface in the horizontal direction is connected to a water tank. One end of the T-shaped connector of the pressure transmitter P1 and the temperature sensor T1. The display of the pressure transmitter and the pressure connecting pipe adopt an inverted thread anti-lock structure to realize the 360° free rotation of the disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com