Light distribution measuring device and method for crop canopy

A crop canopy and measuring device technology, applied in measuring devices, photometry, optical radiation measurement, etc., can solve the problems of difficult adjustment of measuring positions, heavy point measuring instruments, and inability to attach, etc. Accurate, easy-to-adjust effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

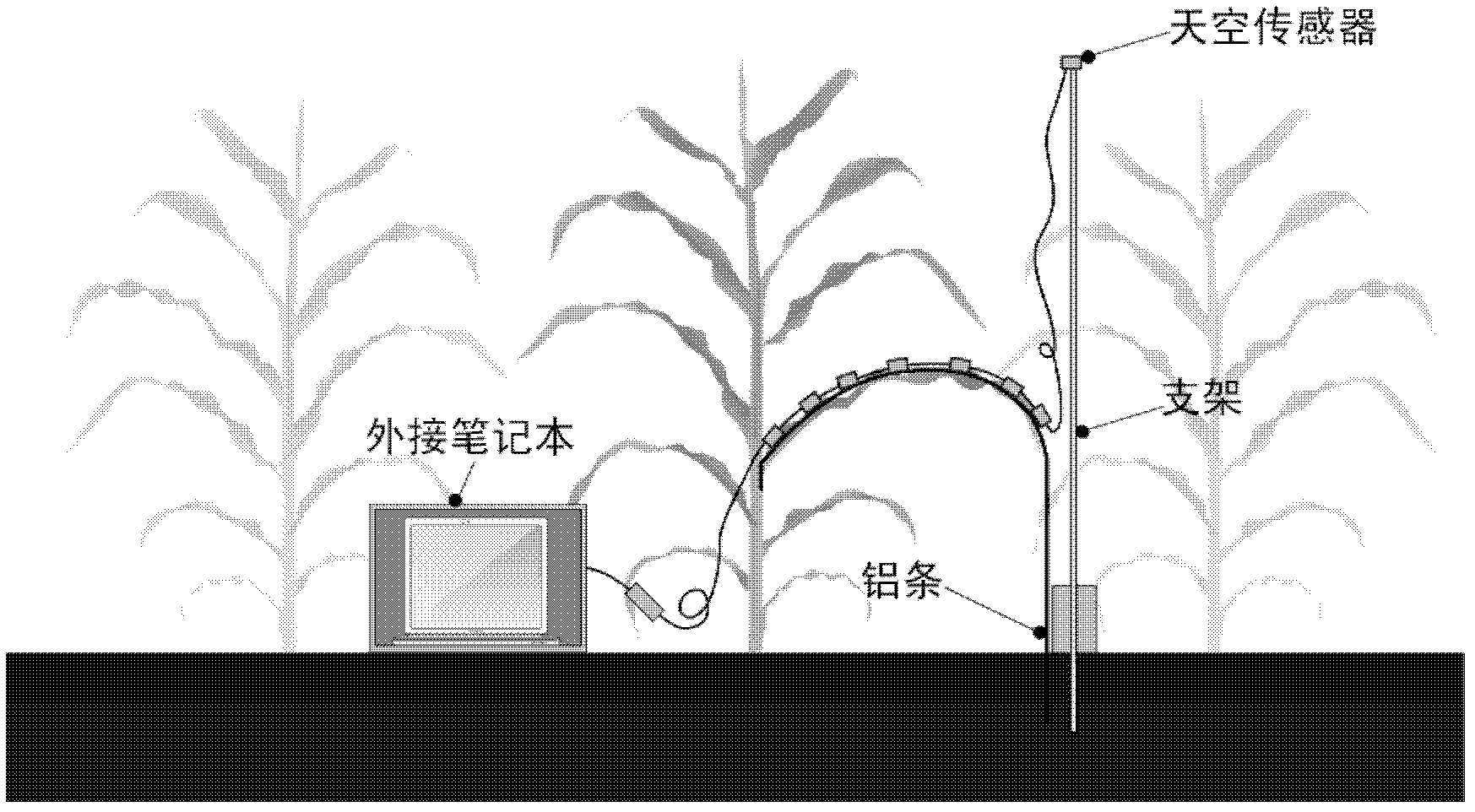

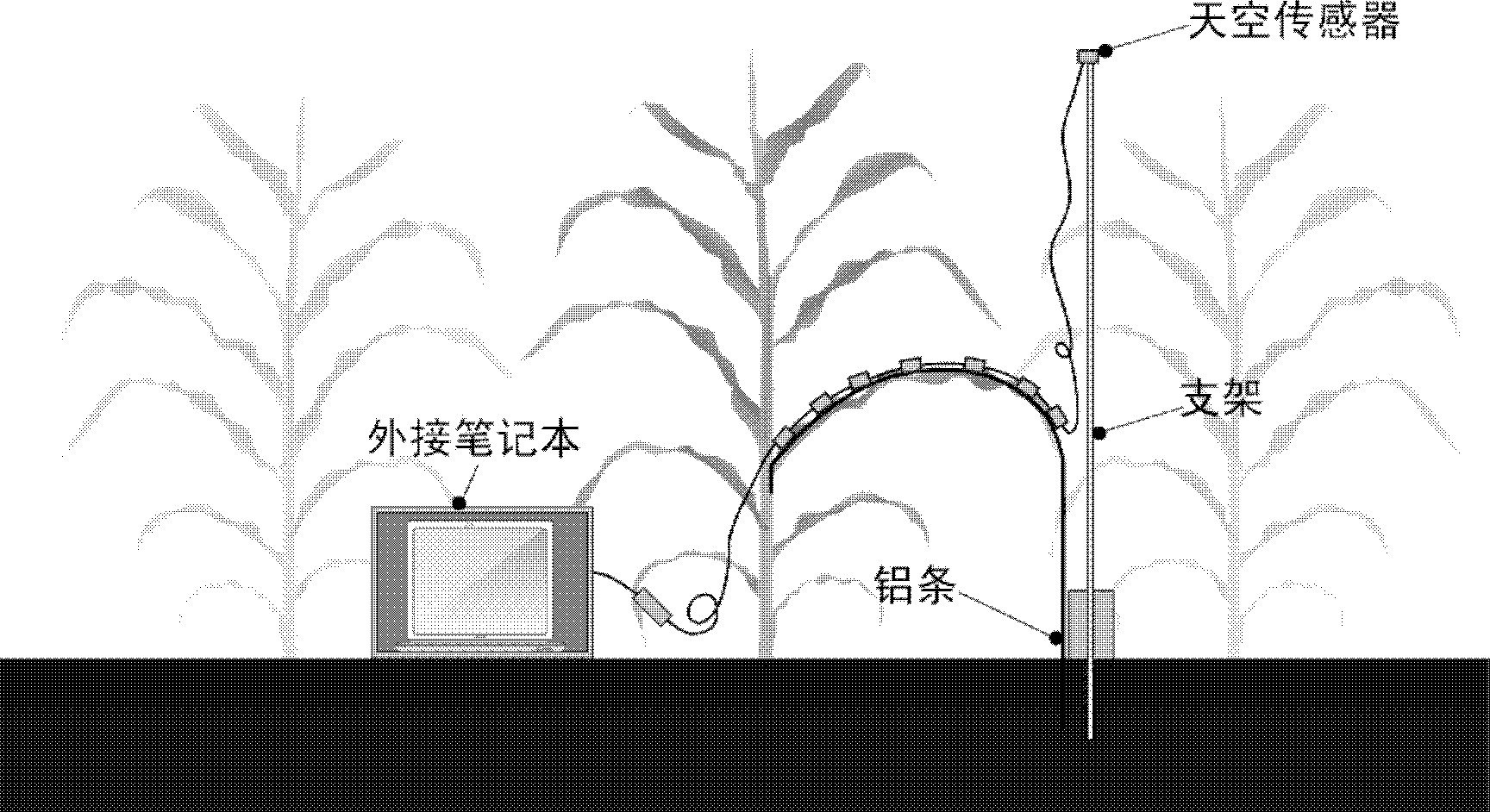

[0040] refer to figure 1 , in this embodiment, since the light sensor is to be placed on the surface of the plant leaf, it is also important to reduce the weight of the sensor while ensuring the measurement accuracy. It has high precision, but when measuring the light distribution in the field, it is easy to cause the light intensity to exceed the range. Therefore, a filter is added to the sensor. Because of the filter, it is necessary to measure the light intensity of different intensities The filter coefficient is determined to restore the collected signal to ensure that the system outputs the correct light intensity value. After measurement, the weight of a single sensor plus an optical filter is 11.90g.

[0041] Due to the limitation of data transmission, each line only allows 8 sensors, and each line is equipped with a notebook (receiving unit) to record data, and the sensors are connected by data lines with low quality, and the data lines are equipped with 15cm, 20cm an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com