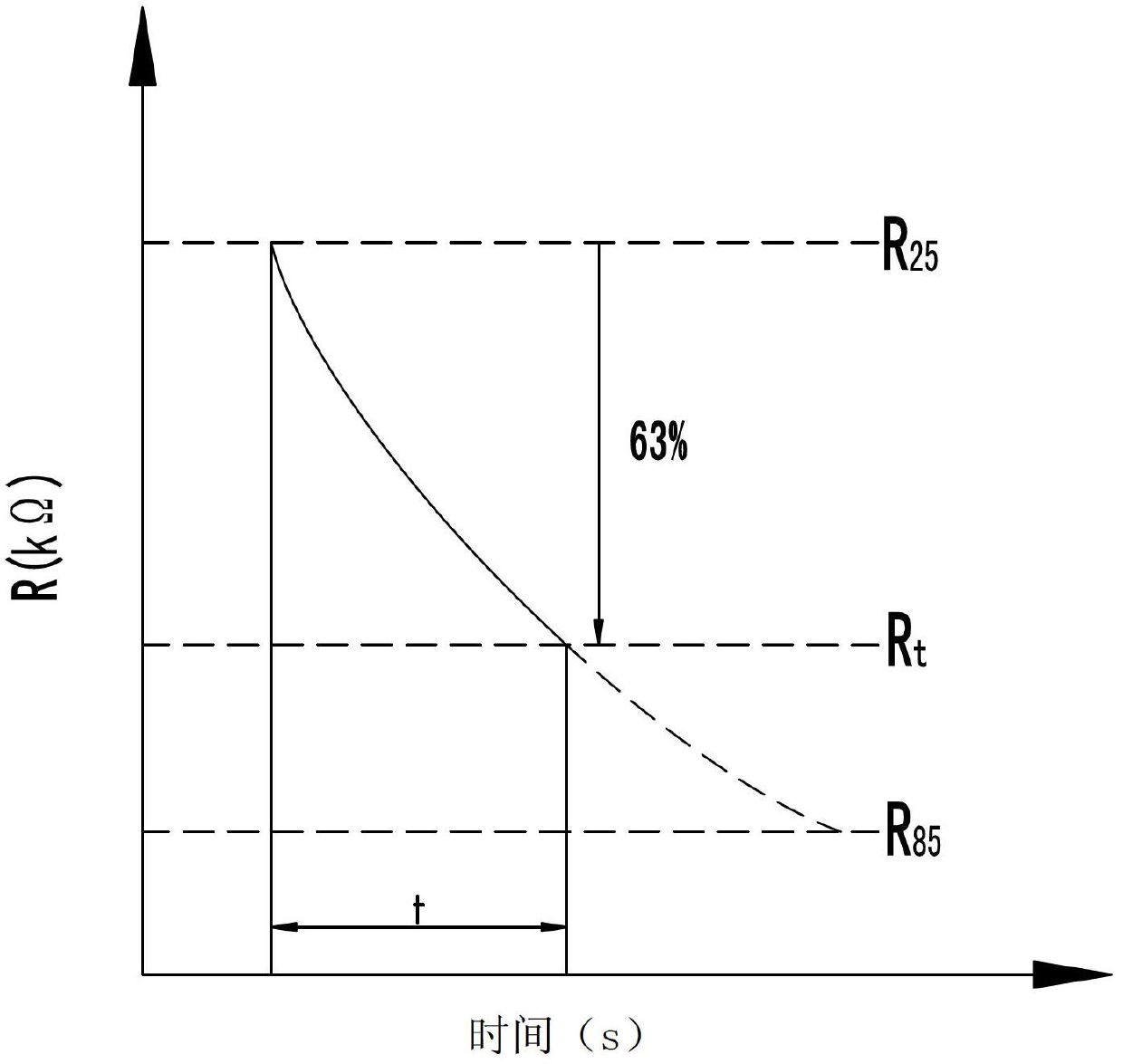

Negative temperature coefficient (NTC) temperature sensor

A temperature sensor, high temperature technology, used in thermometers, instruments, scientific instruments, etc., can solve the problem of sensitivity difficult to meet market requirements, and achieve the effect of considerable production capacity, reasonable shape and structure design, and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

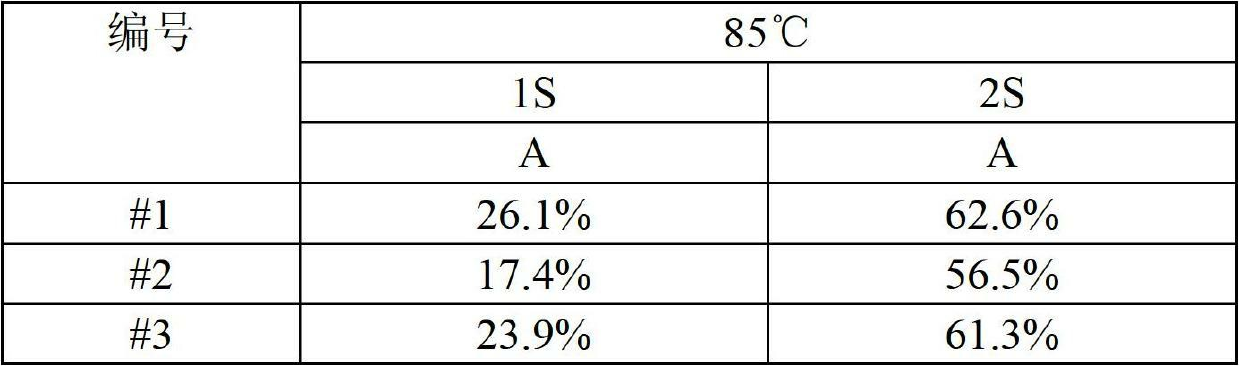

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with embodiment. It should be pointed out that those skilled in the art can make some improvements without departing from the principle of the present invention, and these improvements should also be regarded as the protection scope of the present invention.

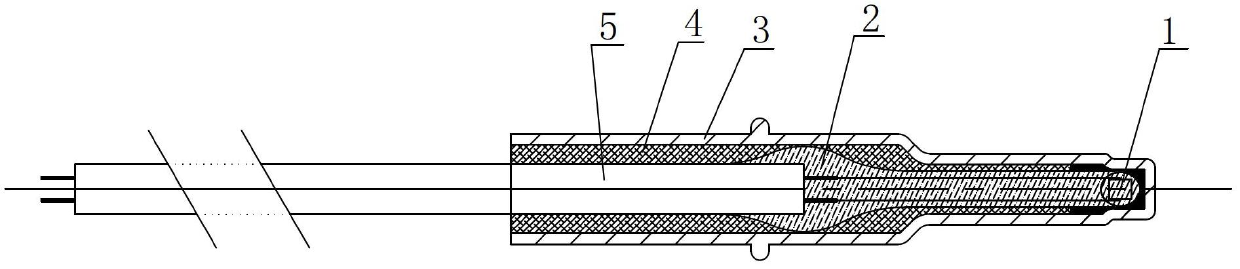

[0015] Such as figure 2 As shown, a kind of NTC temperature sensor comprises silica gel wire 5, NTC thermistor 1, and the end of silica gel wire 5 is welded together with NTC thermistor 1; Part of the outside is sealed with a high-temperature encapsulating adhesive layer 2 with an encapsulating length of 15 mm, and a high-temperature encapsulating adhesive layer 4 is covered outside the high-temperature encapsulating adhesive layer 2, and a casing 3 is covered outside the high-temperature encapsulating adhesive layer 4 . Shell 3 uses bullet-type stainless steel shell 3 and its head is put into special material. The high-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com