Aging test method and device for LED luminaire production

A technology for LED lighting and aging testing, which is applied in the direction of measuring devices, optical instrument testing, and machine/structural component testing, etc. It can solve problems such as ensuring product quality that cannot be scientifically ensured, increasing factory maintenance costs, and large aging electricity bills. The effect of saving test electricity, reducing test site, and reducing aging cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

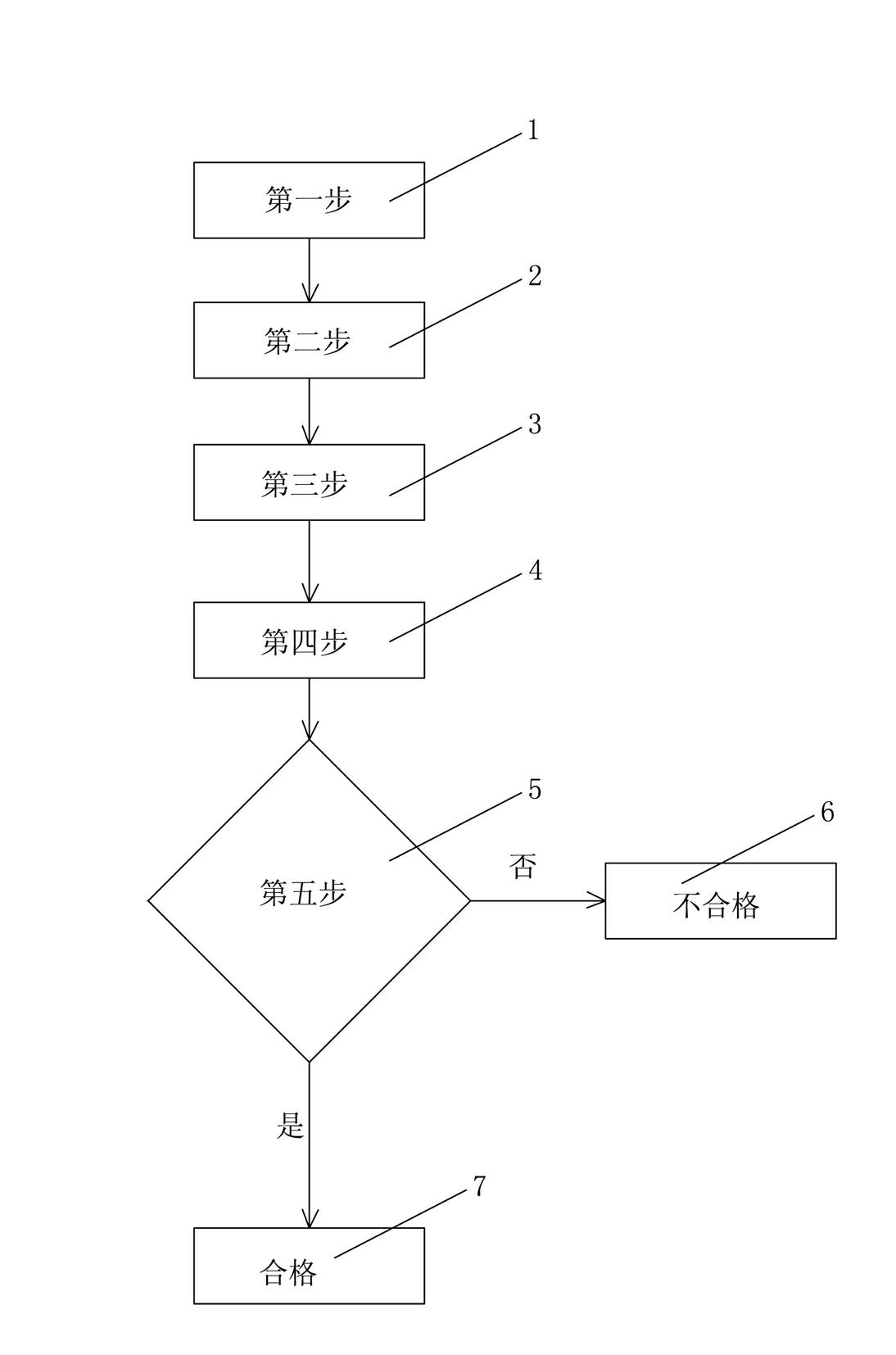

[0022] See figure 1 , figure 1 Disclosed is a production aging test method for LED lamps, including the following steps,

[0023] 1. Select the highest temperature test point in the LED lamp. The highest temperature test point is best to select the place closest to the light emitting part of the LED lamp, such as as close as possible to the pad of the LED lamp bead.

[0024] 2. Select the lowest temperature test point outside the heat dissipation shell of the LED lamp. The lowest temperature test point must be on the outer wall of the LED lamp radiator, and the farther away from the highest temperature test point, the better.

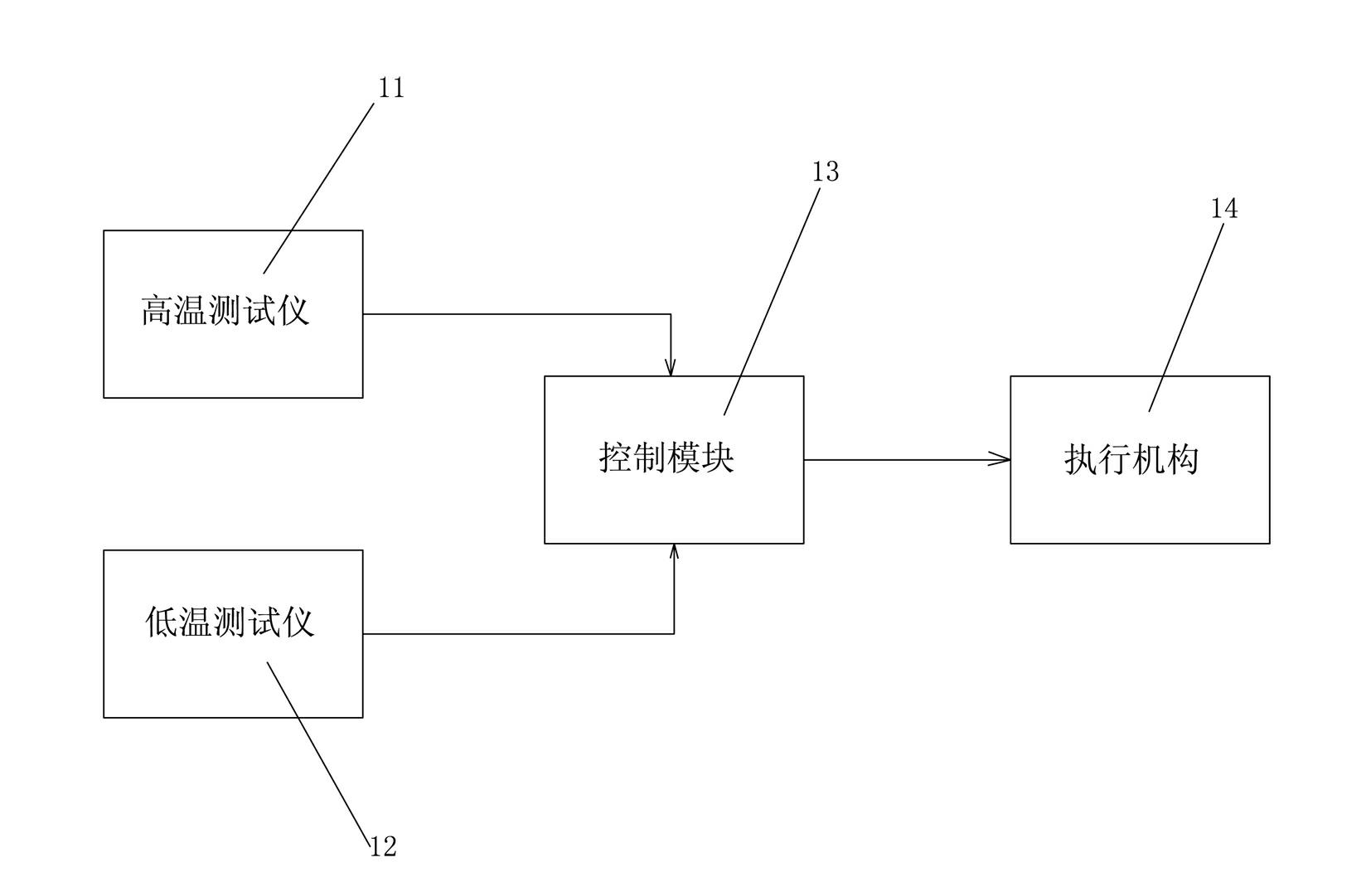

[0025] 3. The temperature sensor of the temperature tester for measuring high temperature is set at the highest temperature test point and the temperature sensor of the temperature tester for measuring low temperature is set at the lowest temperature test point, and the temperature sensor of the temperature tester for measuring high temperature can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com