Distillation method and combined ageing method of solid state brewed liquor

A solid-state brewing and solid-state distillation technology, which is applied in the field of liquor brewing, can solve the problems of slow cycle operation, long storage time, poor process controllability and easy introduction of impurities, etc., and achieve the effects of reducing processing costs, mellow flavor, and great prospects for industrial use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

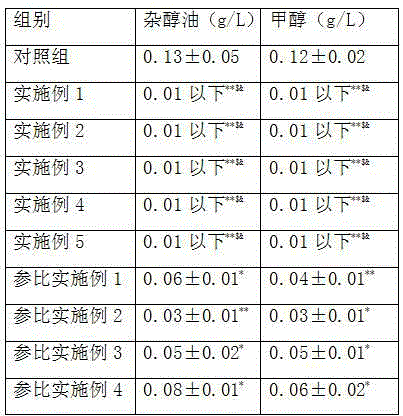

Examples

Embodiment 1

[0028] Embodiment 1 The present invention solid-state brewing liquor distillation method and its combined aging method

[0029] Put the fermented grains to be distilled into a solid-state distillation retort, and pass clean air into the retort with a ventilation volume of 1m 3 / h / 1000kg and heat the fermented grains under normal pressure to maintain the temperature of the fermented grains at 80°C, collect the distillate to obtain distilled liquor, named as base liquor, and take a certain volume according to production requirements as the waiting Handle liquor. Store the wine to be treated in a closed wine storage tank, adjust the alcohol content of the wine to 4 degrees, add glutinous rice saccharification liquid to the wine to make the sugar content of the fermentation liquid 10°Be', add soybeans with 3.00g / 100ml of total nitrogen Hydrolyze 10% of the protein solution, add an enzyme composition containing dextranase, mannase and lipase to the wine so that the contents of th...

Embodiment 2

[0030] Example 2 Distillation method of solid-state brewing liquor and its combined aging method of the present invention

[0031] Put the fermented grains to be distilled into a solid-state distillation retort, and pass clean air into the retort with a ventilation volume of 1m 3 / h / 1000kg and heat the fermented grains under normal pressure to maintain the temperature of the fermented grains at 100°C, collect the distillate to obtain the distilled liquor, which is named as the base liquor, and a certain volume is taken as the waiting time according to the production requirements. Handle liquor. Store the wine liquid to be treated in a closed wine storage tank, adjust the alcohol content of the wine liquid to 12 degrees, add glutinous rice saccharification liquid to the wine liquid to make the sugar content of the fermentation liquid 8 ° Be ', add total nitrogen to be 3.00g / 100ml Soybean hydrolyzed protein solution 7%, add enzyme composition containing dextranase, mannase an...

Embodiment 3

[0032] Example 3 Distillation method of solid-state brewing liquor and its combined aging method of the present invention

[0033] Put the fermented grains to be distilled into a solid-state distillation retort, pass clean air into the retort with a ventilation rate of 1m3 / h / 1000kg, heat the fermented grains under normal pressure to maintain the temperature of the fermented grains at 82°C, collect the distillate Can obtain the distilled liquor, name it as base liquor, get certain volume according to production requirements as liquor to be treated. Store the wine liquid to be treated in a closed wine storage tank, adjust the alcohol content of the wine liquid to be 10 degrees, add glutinous rice saccharification liquid to the wine liquid to make the sugar content of the fermentation liquid 8 ° Be ', add total nitrogen to be 3.00g / 100ml Soybean hydrolyzed protein solution 8%, add enzyme composition containing dextranase, mannase and lipase to the wine liquid, control the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com