Method for extracting high-ester seasoning liquid from after-run

A seasoning liquid and wine tail technology, which is applied in the recovery field of by-products of liquor fermentation, can solve the problem of low extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

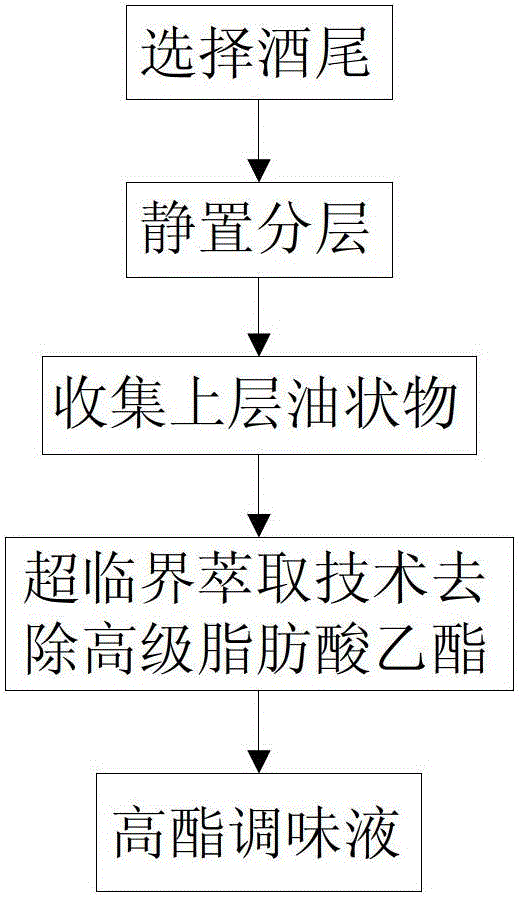

[0019] Embodiment: the method for extracting high-ester seasoning liquid from the wine tail produced in the cellar pond with a longer fermentation period is carried out as follows:

[0020] (1) Selection of wine tails: choose a cellar with a long fermentation period (generally 4 to 6 months), and choose low-alcohol wine tails picked from the fermented grains near the bottom of the pool and distilled in retort barrels as objects; The degree is generally 15% to 20%.

[0021] (2) The pretreatment step of wine tail: put the picked special wine tail in a storage tank and let it stand overnight, and collect the oil floating on the upper layer of the wine tail in the storage tank to obtain the wine tail oil.

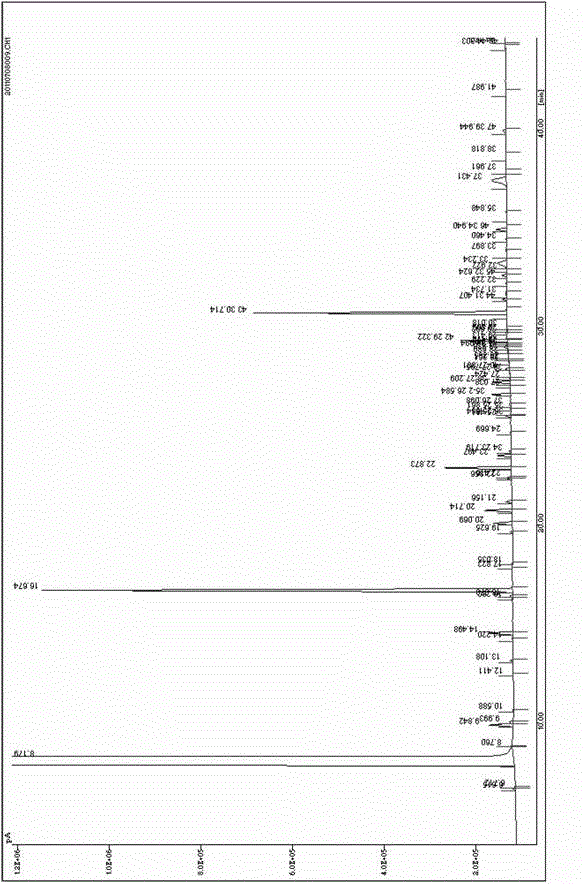

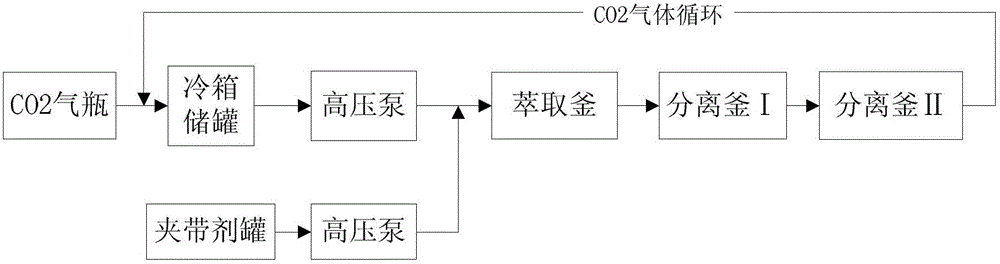

[0022] (3) Extraction and separation step: using supercritical CO 2 extraction unit (the unit includes CO 2 , cold box storage tank, high-pressure pump, etc.) to separate the heavy component (higher fatty acid ethyl ester) and light component (hexyl ester, caproic acid, etc.)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com