Method for improving quality of mechanized Shaoxing rice wine

A technology for rice wine and quality, applied in the field of improving the quality of mechanized Shaoxing rice wine, can solve the problems of poor flavor, simple taste and heavy bitterness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

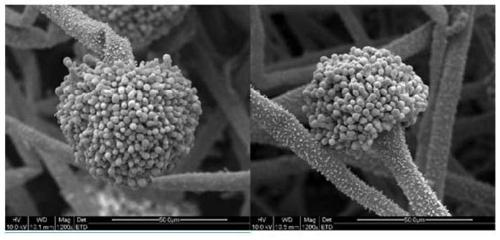

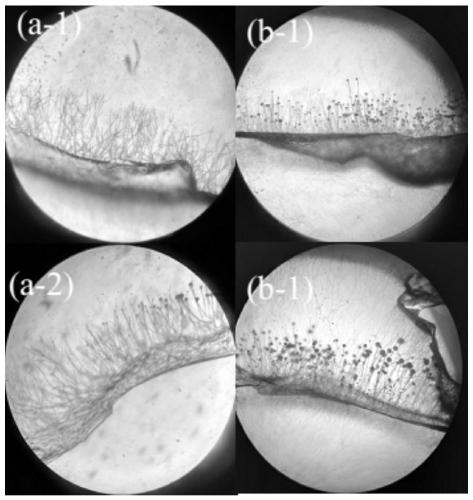

[0067] Aspergillus oryzae SR-201 with high saccharification ability was screened from naturally cultured wheat koji in Shaoxing rice wine, and further induced by ultraviolet radiation. The bacterial strain SR-201 of screening carries out physiological characteristic identification according to " taxonomy of microorganisms ", as can be seen, Aspergillus oryzae SR-201 provided by the invention is in PDA culture medium (potato 200g, glucose 20g, agar 15~20g, distilled water 1000mL, natural pH ) was initially white and round, and then gradually turned yellow in the middle of the colony, and finally turned brown to light greenish brown. The back of the colony was colorless and loose in texture. The spores germinate on the PDA medium at 30°C, and the diameter of the colony reaches 32-35mm in 3 days and 60-70mm in 5 days, and the amount of spore production is equivalent to that of Su-16; ~80μm, the entire surface of the apical capsule is fertile, the surface of the conidiophores is r...

Embodiment 2

[0070] The ITS rDNA sequence of the SR-201 strain of the present invention is shown in SEQ ID NO.1, and Blast comparison is carried out in GenBank to determine its species. The strain with the highest sequence homology is Aspergillus oryzae. The similarity 99%.

Embodiment 3

[0071] Example 3 Using SR-201 as the production strain to prepare wheat koji for mechanized rice wine

[0072] (1) Cultivation of strains on slant: 13 ° Bx malt juice agar medium was used as the culture medium for slant test tubes. After inserting the SR-201 strain under sterile conditions, it was cultivated at 30°C for 5 days. The strain was Aspergillus oryzae SR-201;

[0073] (2) First-level koji cultivation: mix the bran and water evenly in a mass ratio of 1:0.7 to obtain the bran mixed with water, add the bran mixed with water into the Erlenmeyer flask, plug a tampon, Wrap with moisture-proof paper and sterilize at 121°C for 30 minutes. After the sterilization is complete, shake off the lumps in the Erlenmeyer flask while it is hot, cool to 32°C and insert the slant strains, shake well, cultivate at 30°C, and shake after 24 hours. Evenly, continue to cultivate for 24 hours to buckle the bottle, and then cultivate for 45 hours to be covered with yellow-green spores to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com