Method and system for measuring simulation friction coefficient of belt conveyor

A belt conveyor, friction coefficient technology, used in measuring devices, mechanical devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

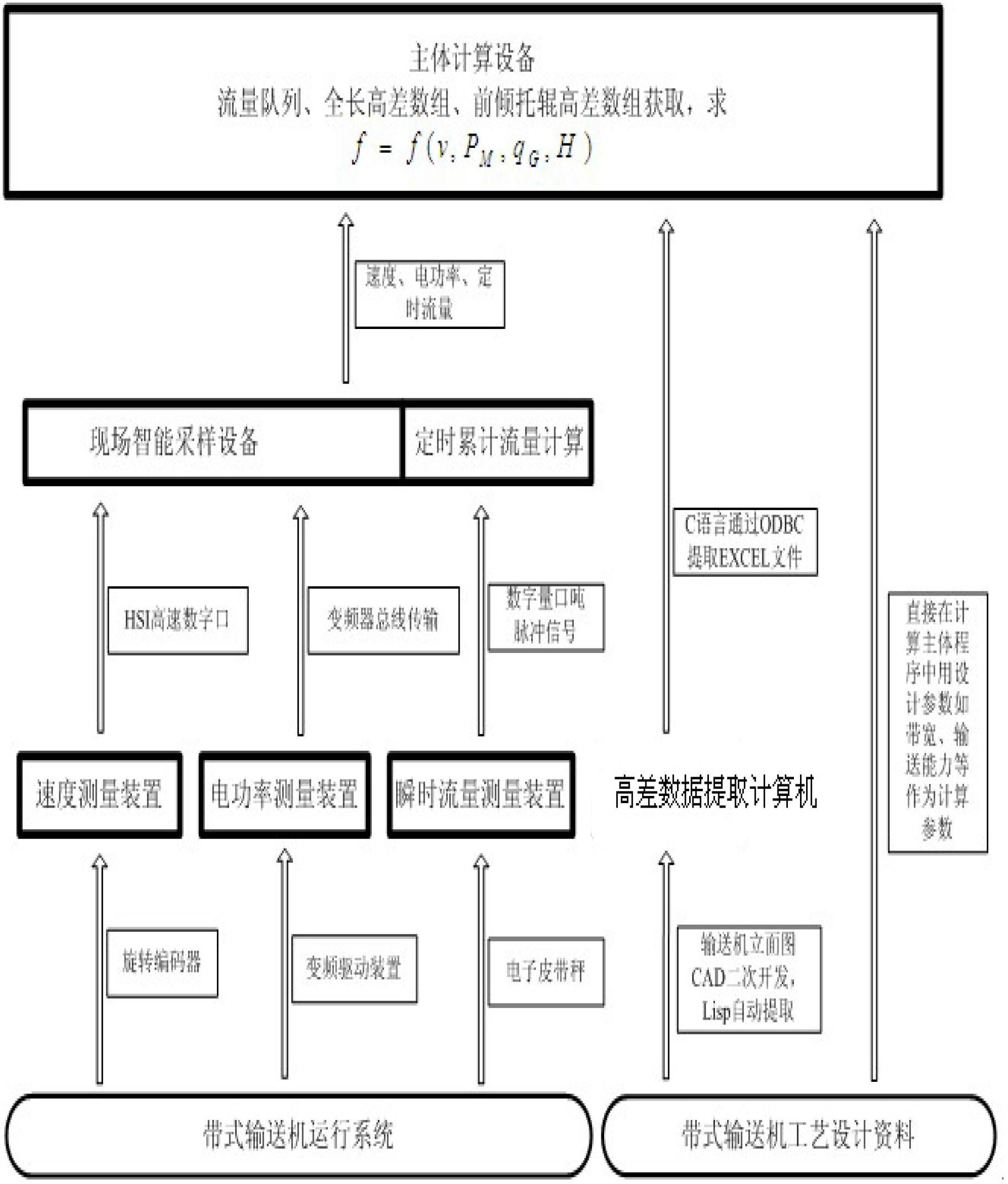

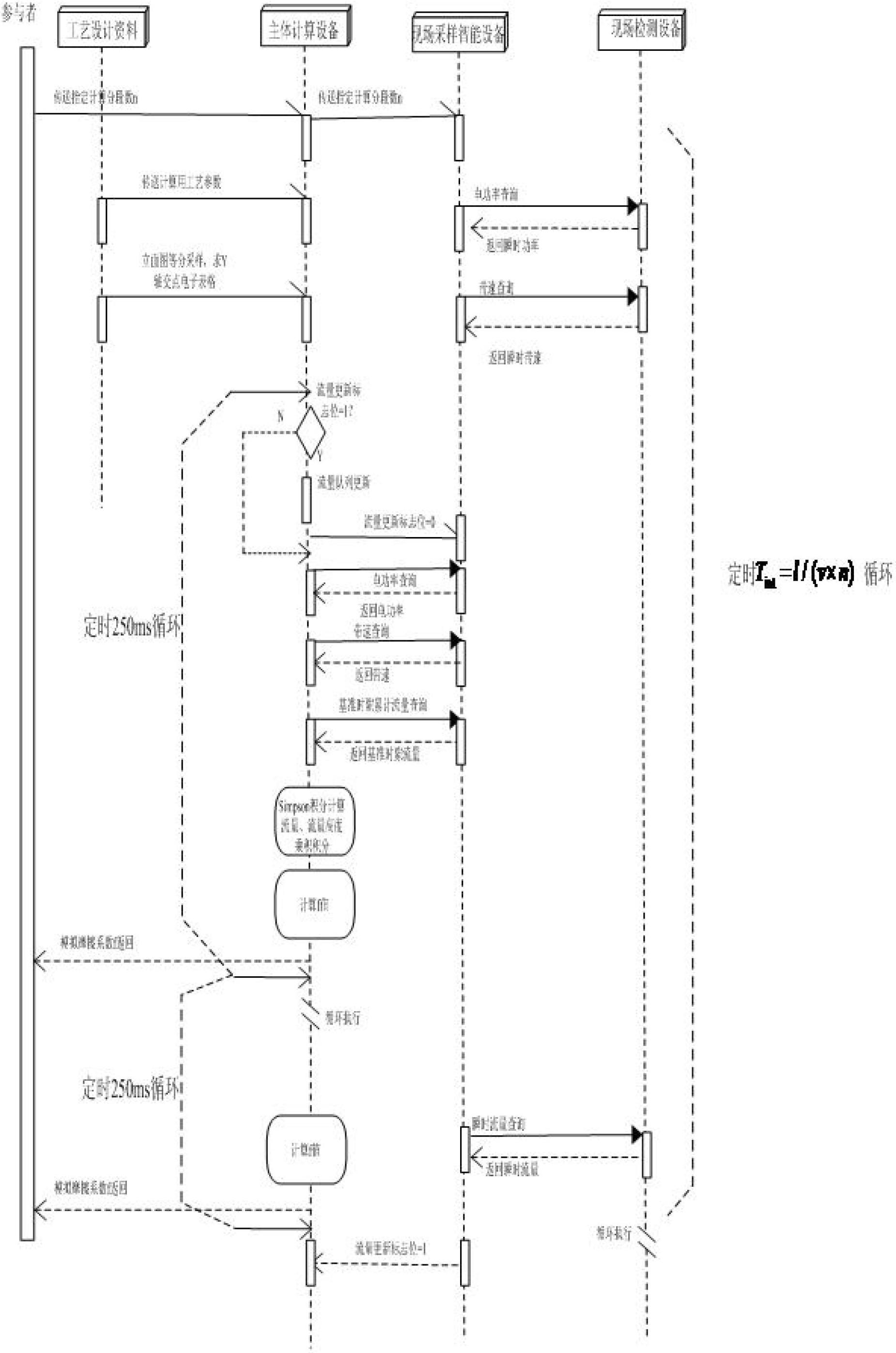

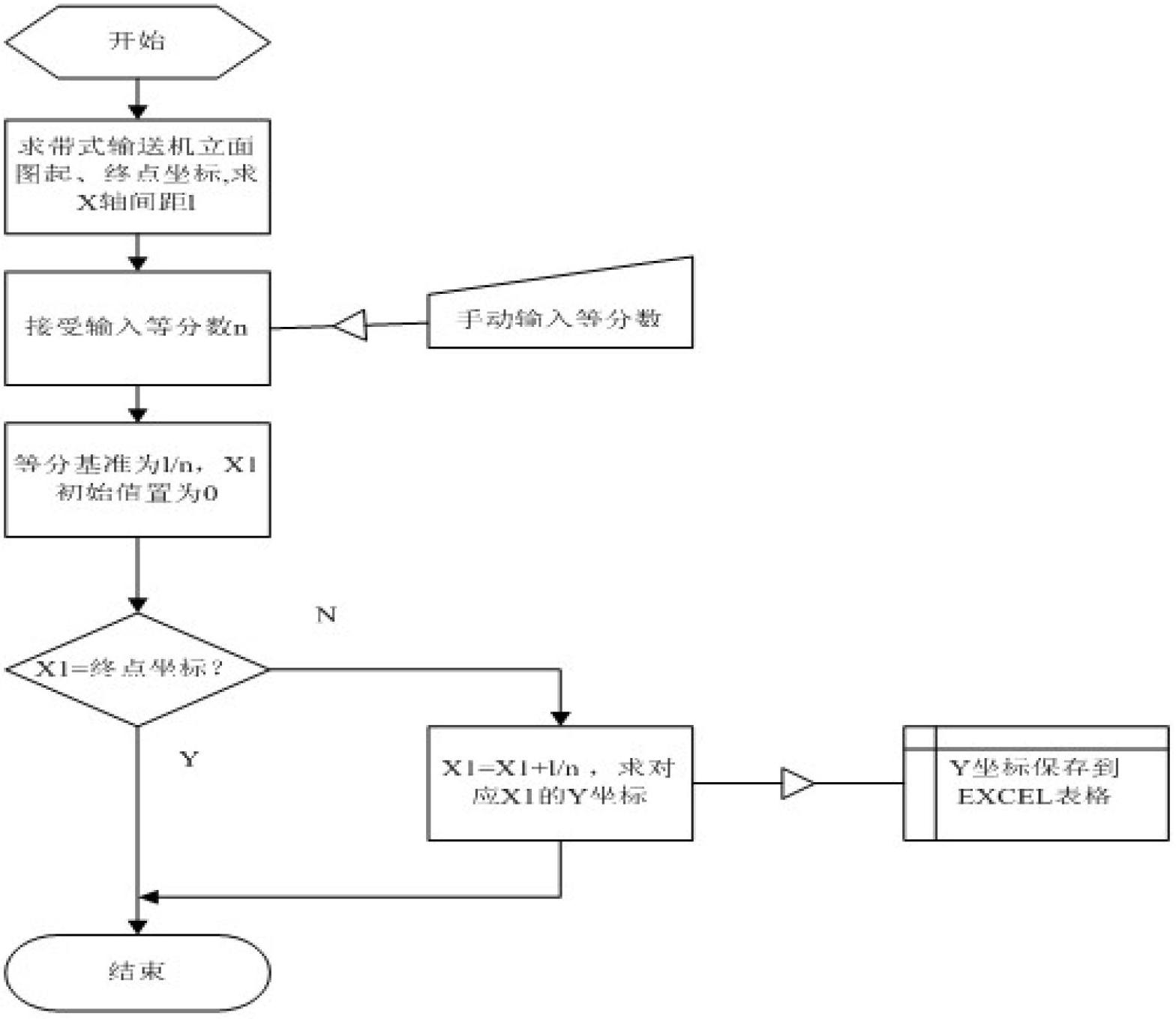

[0048] Embodiment of the present invention: a kind of measurement system of the simulated friction coefficient of belt conveyor, such as figure 1 As shown, it includes: the main calculation equipment for flow distribution queue formation and simulation friction coefficient calculation 1, for real-time measurement of the operating electric power, operating belt speed, instantaneous flow and the reference time slot for instantaneous flow of the belt conveyor in operation The intelligent system 2 for on-site sampling that carries out integral processing, the height difference data extraction computer 3 for automatically generating the sampling height difference electronic form for saving the height difference information of the sampling interval, and the intelligent system 2 for on-site sampling includes: The on-site intelligent sampling device 4 composed of a programmable logic controller is used to accumulate the flow value in the sampling interval and store and forward the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com