Device for detecting defect on surface of steel billet

A billet and defect technology, applied in the field of testing equipment, can solve the problems of not very objective judgment of billet quality, manual observation, unfavorable surface conditions, etc., achieve good social and economic prospects, avoid deep processing, and have excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

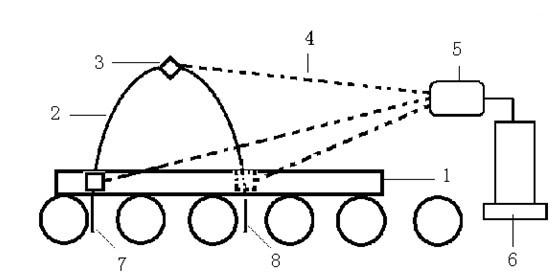

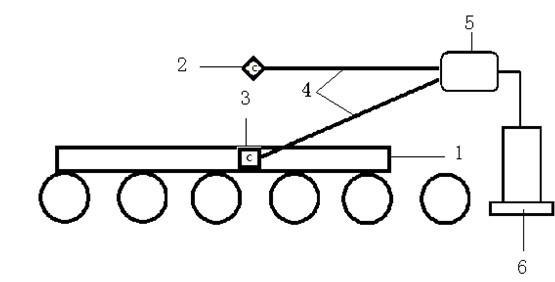

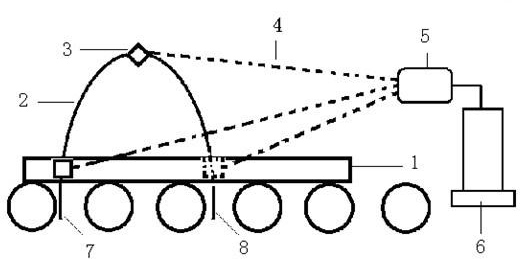

[0010] The invention is a machine vision-based object surface defect detection device through imaging-analysis-result-operation, which consists of a fixing device, a collection device, a processing device and a control device. The fixing device is a sliding track 2 , the acquisition device is an industrial camera 3 or a related image acquisition device, and the processing device includes an industrial computer 6 and a PLC cabinet 5 .

[0011] The PLC cabinet 5 is connected to the industrial camera 3 and the industrial computer 6 respectively, and the operation monitoring HMI of the industrial computer 6 includes hardware and screen writing software.

[0012] The industrial computer 6 is carried out according to the edited logic algorithm. The algorithm includes the recognition algorithm for the upper surface of the billet and the recognition algorithm for the two sides of the billet according to the different detection positions. According to the recognition steps, it is divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com