Performance testing system and performance testing method for portable motor

A test system and portable technology, applied in the field of portable motor performance test systems, can solve problems such as inability to test small micro-motors, and achieve the effects of improving equipment practicability, stable operation, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

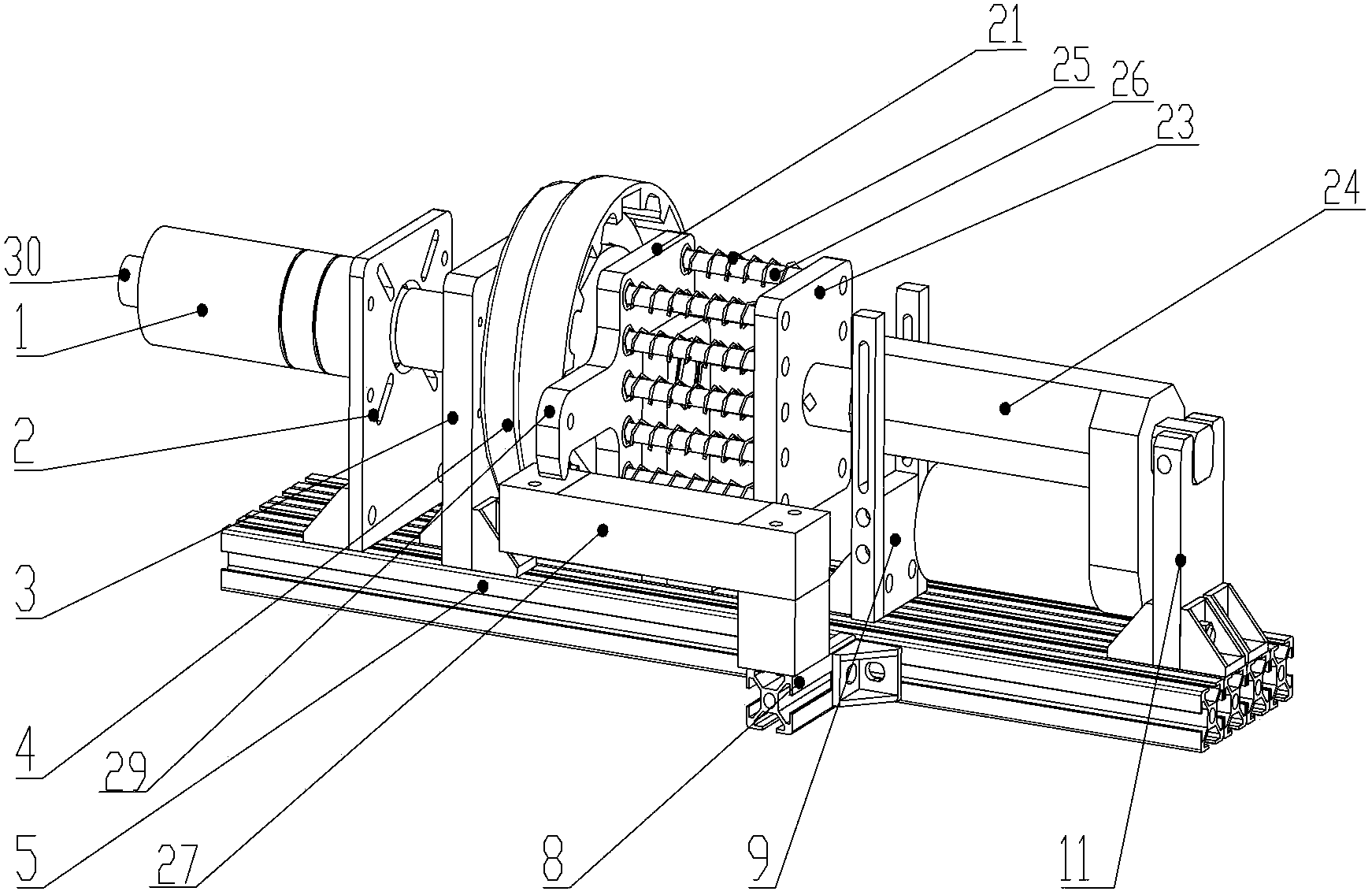

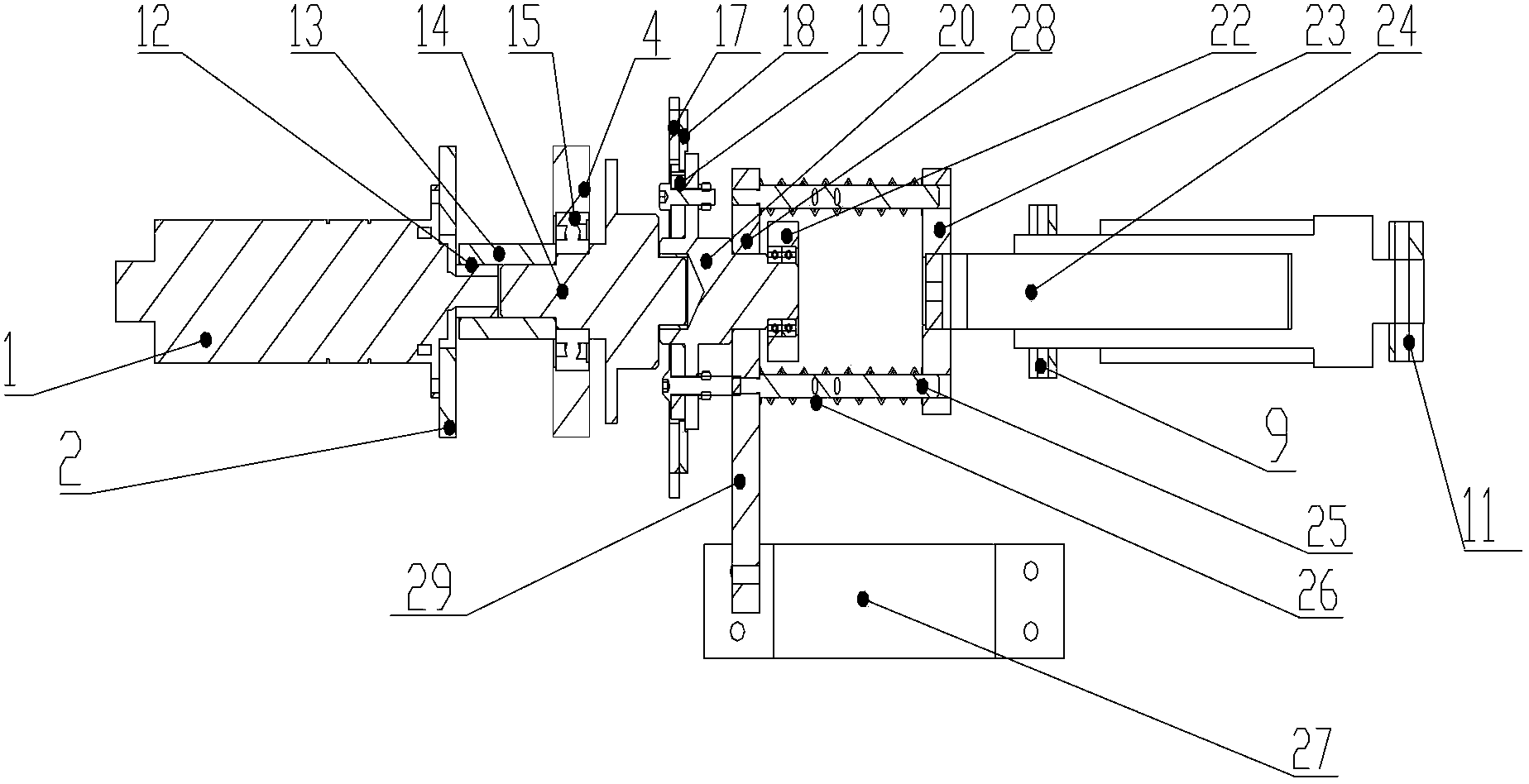

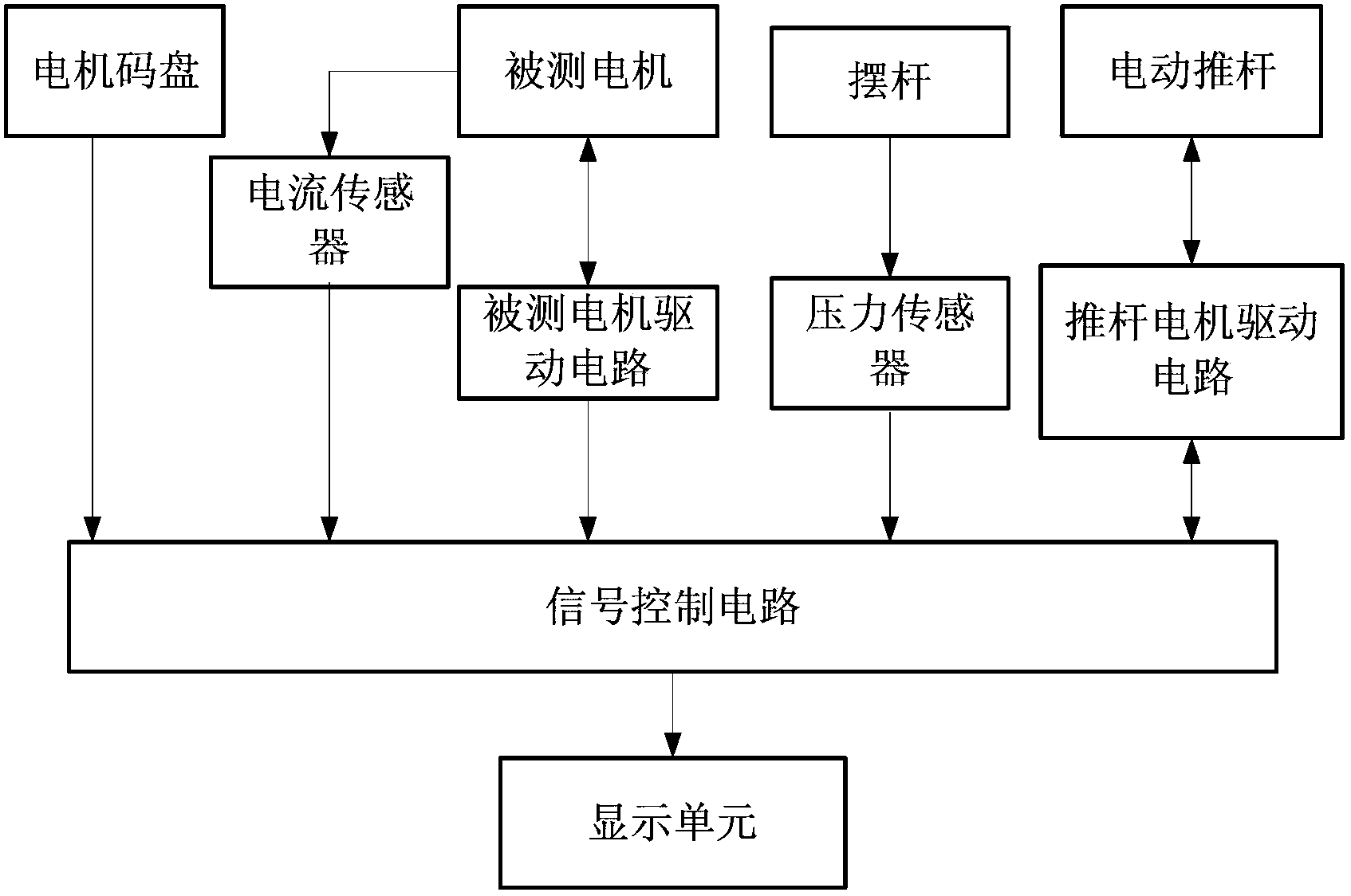

[0028] Specific implementation mode one. The following combination figure 1 and figure 2 Describe this embodiment, a portable motor performance testing system, which includes a device bracket, a power unit, a friction unit, a measurement unit, an elastic loading unit and an electronic control unit;

[0029] The device bracket provides support and positioning for the power unit, the friction unit, the elastic loading unit, the pressure measurement unit and the electric control unit;

[0030] The power unit includes a shaft sleeve 12 and a steel sleeve coupling 13, the outer side of the output shaft of the motor 1 under test is covered with a shaft sleeve 12, and the output shaft is connected to the input shaft of the friction unit through the steel sleeve coupling 13,

[0031] The friction unit includes a friction device driving shaft 14, a friction device outer pressure plate 4, a moving friction plate 17, a static friction plate 18 and a friction device driven shaft 20, whe...

specific Embodiment approach 2

[0039] Specific implementation mode two. The following combination figure 1 and figure 2This embodiment is described. This embodiment is a further description of the device bracket of Embodiment 1, a portable motor performance testing system. The device bracket includes a motor support plate 2 under test, a friction unit support plate 3, a bottom plate Base plate 8, push rod front frame 9, push rod tail frame 11 and bearing frame 22;

[0040] The tested motor support plate 2 is fixed on the bottom plate 5 for supporting the tested motor 1;

[0041] The friction unit support plate 3 is fixed on the bottom plate 5, and a bearing is installed in its center to support the friction unit, and the bearing is coaxial with the input shaft of the friction unit;

[0042] The support bottom plate 8 is connected to one side of the bottom plate 5 through profile corner fittings, and is used to support the pressure sensor support 7;

[0043] The push rod front frame 9 and the push rod ta...

specific Embodiment approach 3

[0045] Specific implementation mode three. The following combination figure 1 and figure 2 This embodiment is described. This embodiment is a further description of the bushing in Embodiment 1, a portable motor performance testing system. The bushing 12 is a bushing matched with a D-shaped shaft or a flat keyed shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com