Electronically controlled fluid gas density stabilizing device for spectrograph

An electronic control and gas density technology, which is applied in the field of detection and analysis of spectrometers, can solve the problems of high machining accuracy, difficult debugging, and difficult control accuracy, achieving high-precision density control and improving measurement stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to the following examples.

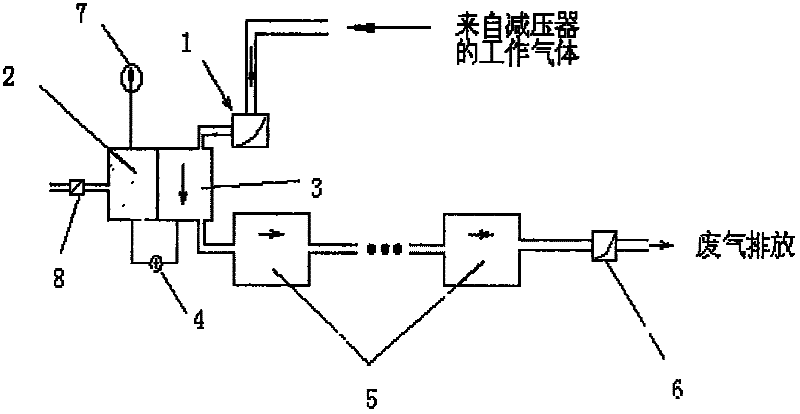

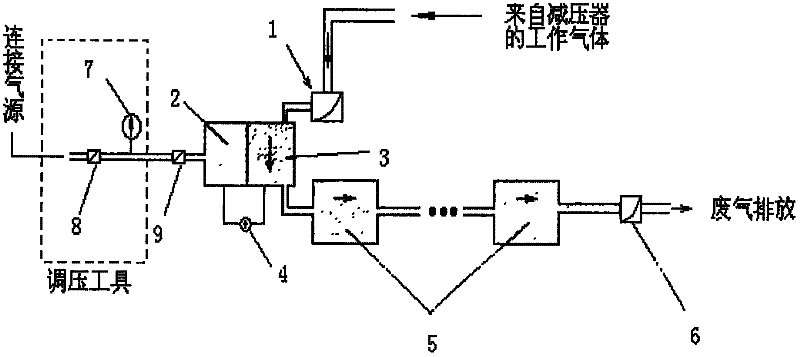

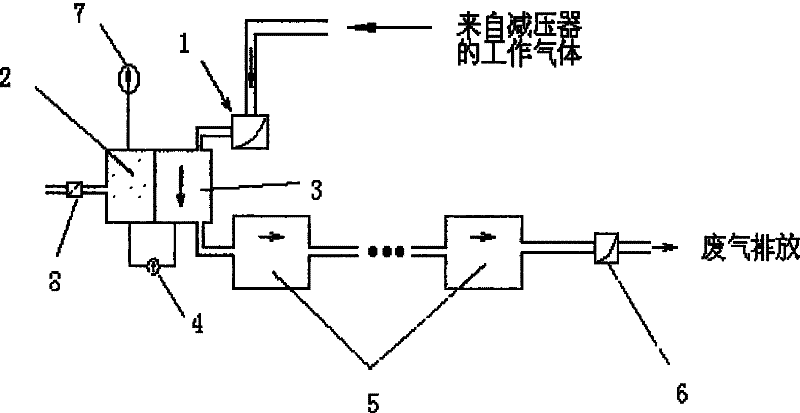

[0017] Such as figure 1 It is the flow chart of adjusting the preset pressure of the airtight chamber of the present invention; the working gas from the pressure reducer enters the flow chamber 3 through the micro-flow proportional control valve 1, and the gas micro-pressure difference sensor 4 is connected between the flow chamber 3 and the airtight chamber 2 , the airtight chamber 2 is pre-filled with the working gas higher than the working pressure through the regulating valve 8, the gas pressure is monitored by the absolute pressure sensor 7, and then the proper working pressure is achieved by adjusting a small amount of deflation with the regulating valve 8, which may need to be repeated The proper pressure can only be reached by degassing again, and finally the regulating valve 8 is closed. The flow cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com