Sodium-cooled fast reactor full-automatic fuel exchange control method and control system

A sodium-cooled fast reactor and control method technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problem of prolonging the refueling time, reducing the safety and reliability of refueling, and increasing the failure rate, etc. problem, achieve the effect of reducing time, realizing automatic control of refueling, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

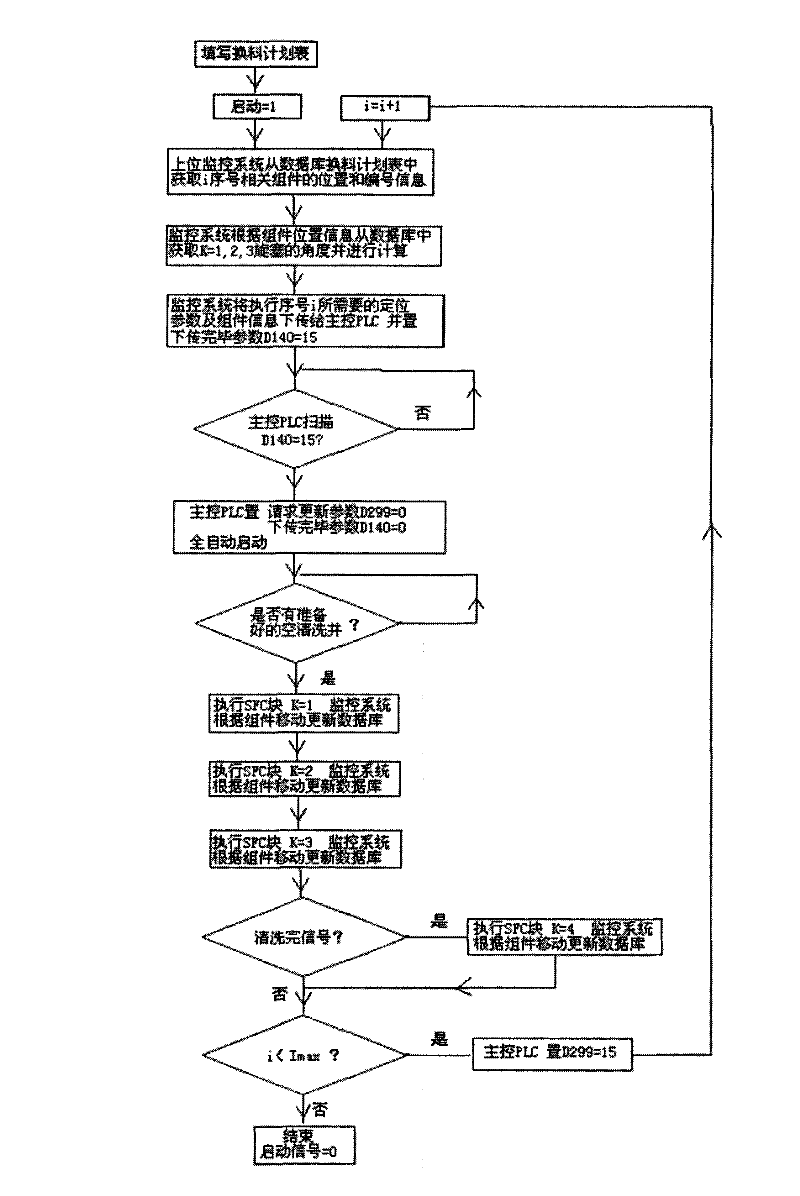

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

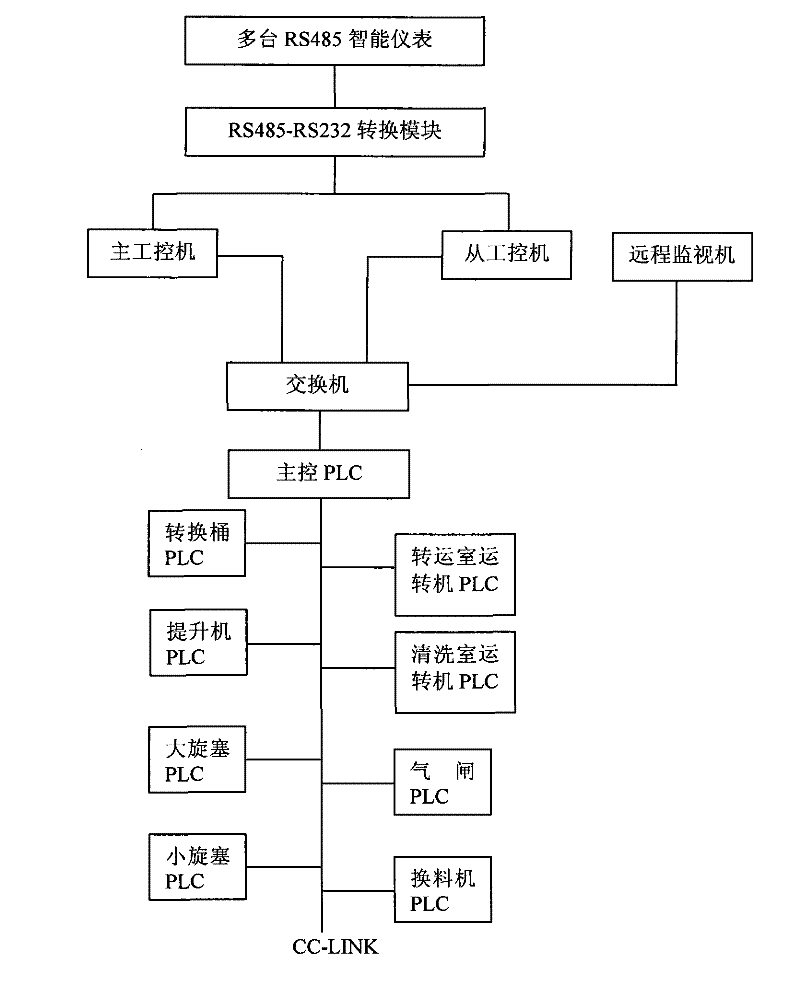

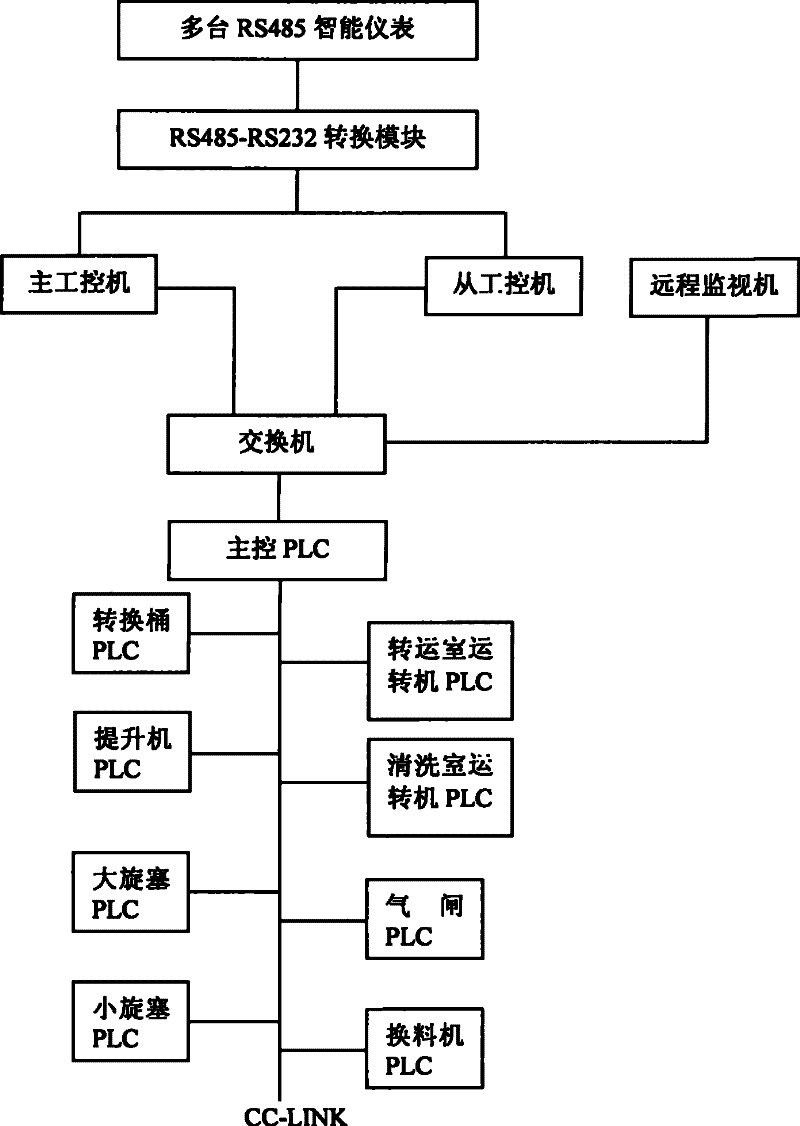

[0021] The main refueling equipment of the sodium-cooled fast reactor includes: cock, refueling machine, loading and unloading hoist, transfer room transfer machine, cleaning room transfer machine, transfer barrel, airlock, etc. Through the cooperative movement of the above-mentioned equipment, the transportation of various components from the inside of the pile to the outside of the pile is completed. The refueling process is as follows:

[0022] 1) Use the transfer machine in the transfer room to transport the new components to the bucket of the loading hoist through the conversion barrel, air lock and other equipment;

[0023] 2) The new components that have been loaded into the bucket of the loading hoist are transported to the lower position in the stack by the loading hoist, and finally transported to the designated position in the stack by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com