Die bonder

A technology of bonding crystals and grains, which is applied in the manufacture of conveyor objects, electrical components, semiconductors/solid-state devices, etc., can solve problems that affect the overall process time and efficiency, do not meet production requirements, and long operating hours, etc., to shorten the operation Time, good precision, and faster production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Specific embodiments of the present invention are described below with specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

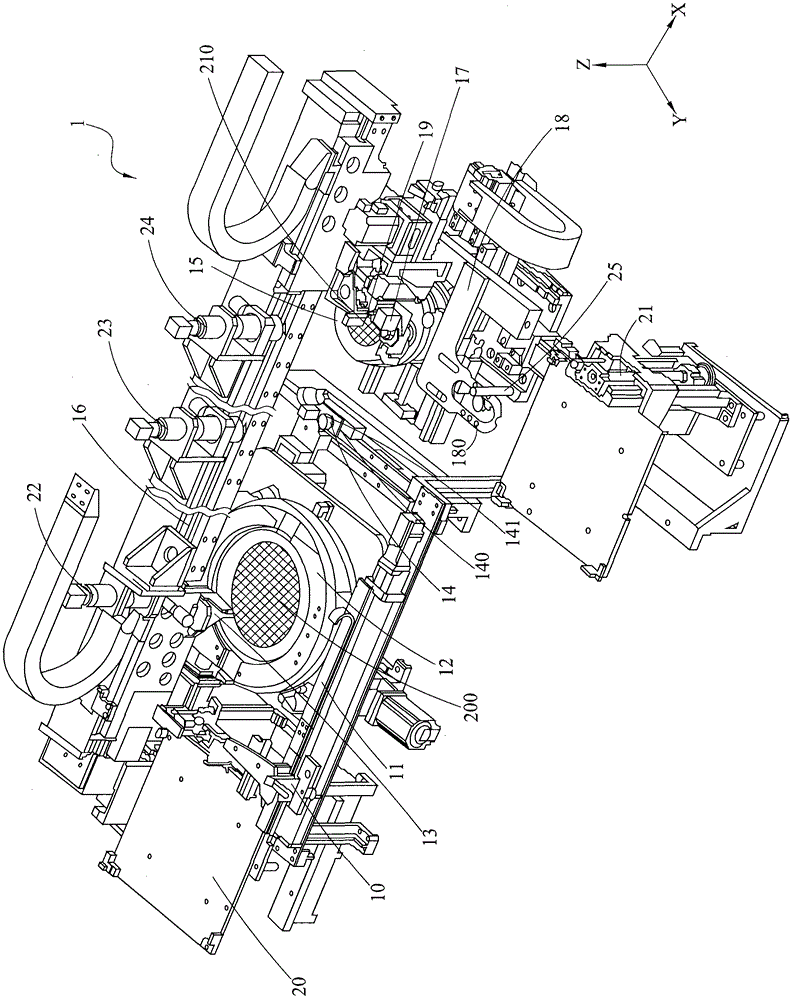

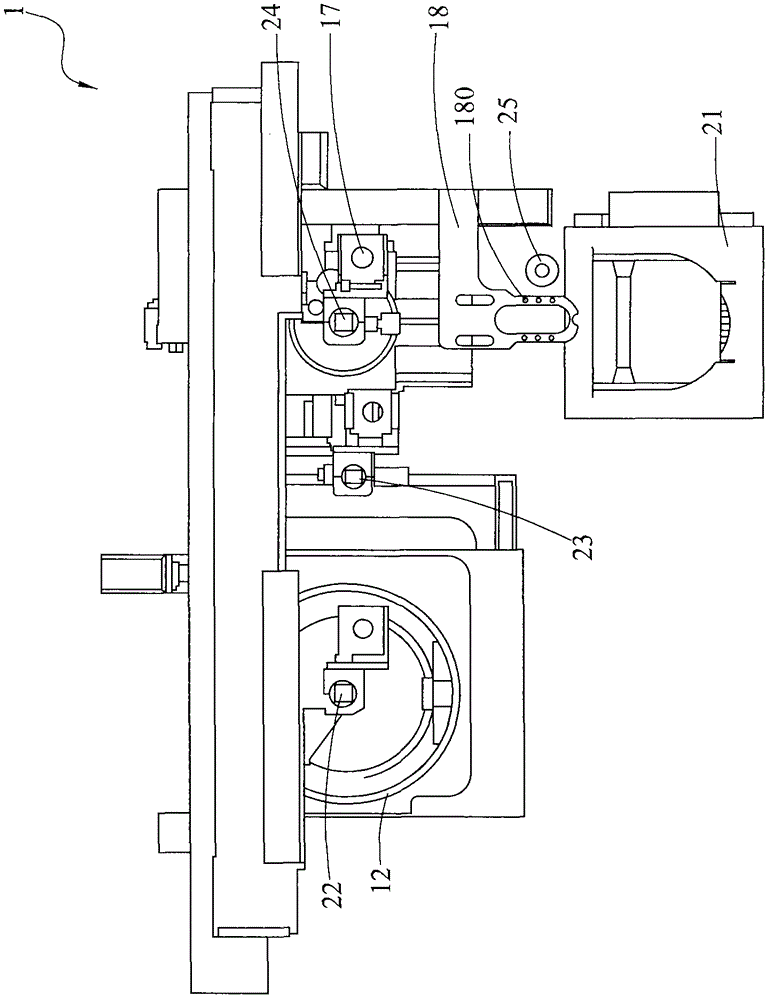

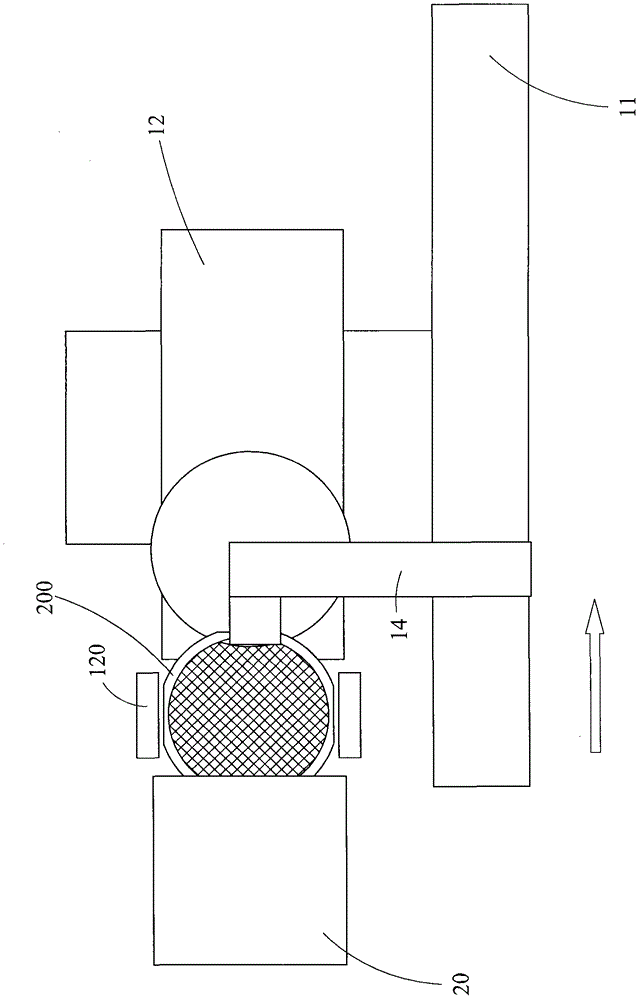

[0052] Please cooperate with reference figure 1 and figure 2 As shown, the present invention is a die bonding machine, which has a machine platform 1, a die ring moving device 10, a first slide rail 11, a die ring carrying device 12, a first pick-and-place device 13, A grain positioning device 14, a substrate carrying device 15, a second slide rail group 16, a dispensing module 17, a substrate moving device 18, a second pick-and-place device 19, a grain basket lifting device 20, a crystal The boat box lifting device 21 , a first vision module 22 , a second vision module 23 , a third vision module 24 , and a substrate positioning device 25 .

[0053] The machine 1 has an X axis, a Y axis and a Z axis.

[0054] The die ring c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com