Horizontal Radiating Antenna

A radiation antenna, horizontal direction technology, applied in the direction of antenna, resonant antenna, antenna grounding device, etc., can solve the problems of hindering electromagnetic wave transmission, power leakage, etc., and achieve the effect of easy connection and improved radiation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

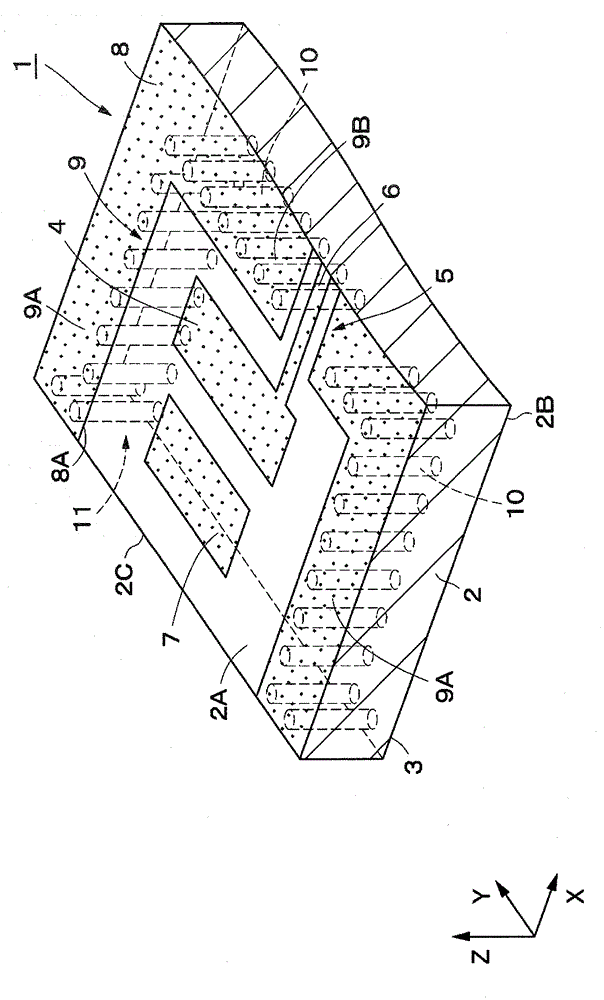

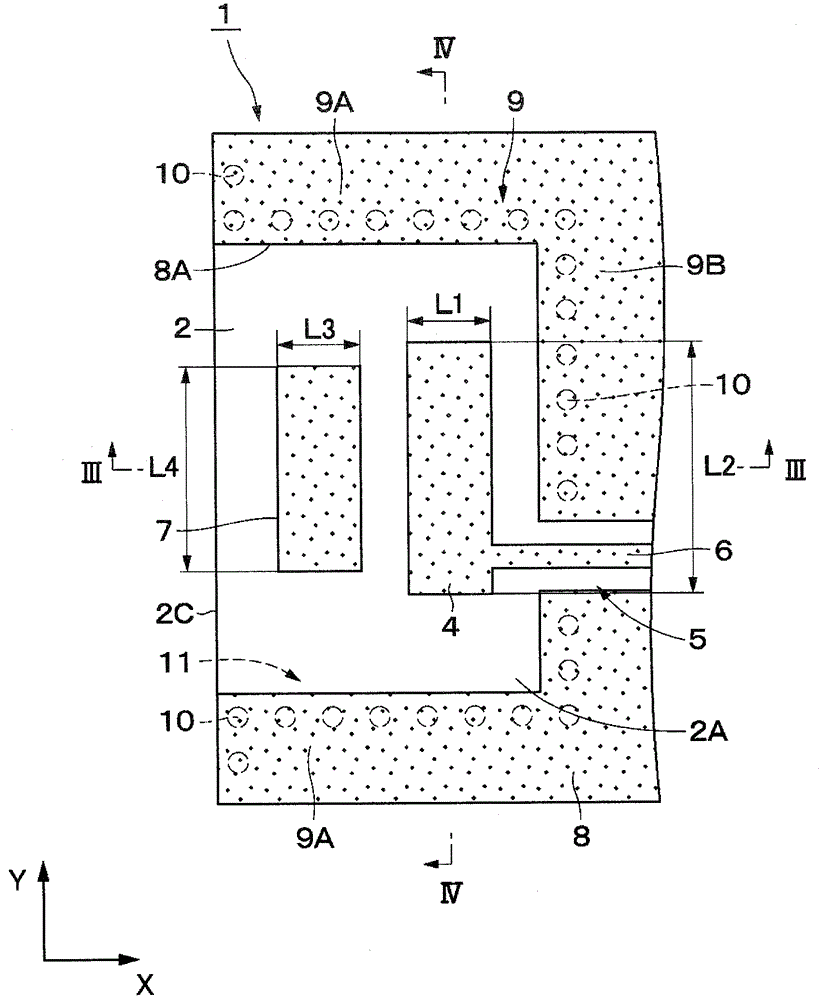

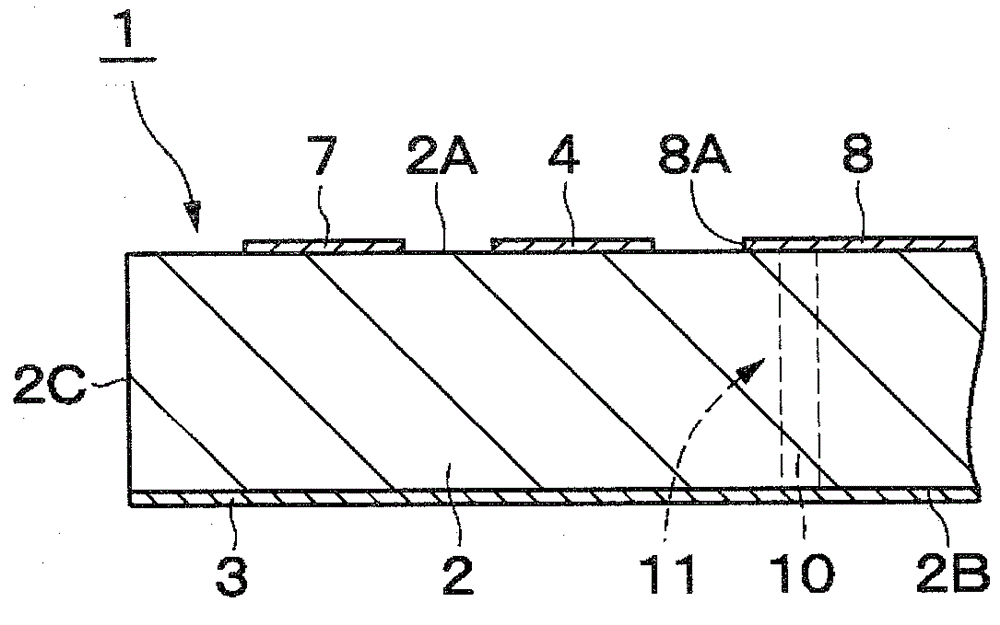

[0052] Hereinafter, as a horizontal radiation antenna according to an embodiment of the present invention, an antenna used in a 60 GHz frequency band will be described in detail with reference to the drawings.

[0053] Figure 1 ~ Figure 4 The horizontal direction radiation antenna 1 of the first embodiment is shown. The horizontal radiation antenna 1 is composed of a substrate 2 , a back side ground conductor plate 3 , a radiation element 4 , a parasitic element 7 , a front side ground conductor plate 8 and the like which will be described later.

[0054] The substrate 2 is formed in a flat plate shape extending parallel to, for example, the X-axis direction and the Y-axis direction among mutually orthogonal X-axis directions, Y-axis directions, and Z-axis directions. The substrate 2 has, for example, a width dimension of about several mm with respect to the Y-axis direction serving as the width direction, has a length dimension of, for example, about several mm with respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com