Solid catalyst for hydration of epoxy compound to prepare diol and its application

A solid catalyst, epoxy compound technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, hydrolysis preparation, etc., can solve the problem of poor EG selectivity, long process flow, high energy consumption, etc. problem, to achieve the effect of preventing influence, good technical effect and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of catalyst in the present invention.

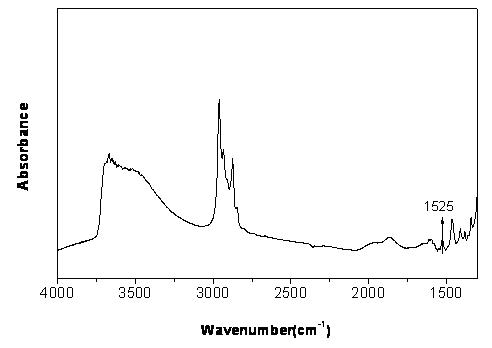

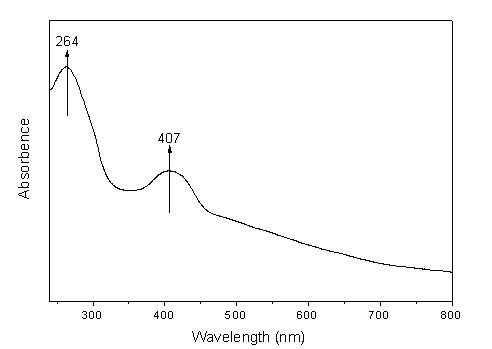

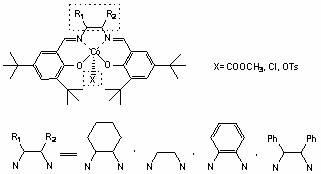

[0032] 0.05 g of Co(salen)-COOCH with cyclohexanediamine skeleton 3 1g of the cage-type pore material FDU-12 was uniformly dispersed in 5mL of dichloromethane, refluxed for 12 hours, cooled, and the solvent was drained, then 2mL of n-hexane, 1mL of pyridine and 10mmol of trimethoxypropylsilane were added and stirred. Reflux for 12h, cool, filter and wash, and dry to obtain catalyst A, whose infrared and ultraviolet characterizations are shown in the attached figure 1 and 2 .

Embodiment 2

[0034] Co(salen)-COOCH using 0.10 g of cyclohexanediamine skeleton 3 , all the other operating steps are the same as embodiment 1, called catalyst B.

Embodiment 3

[0036] Co(salen)-COOCH using 0.15 g of cyclohexanediamine skeleton 3 , and all the other operating steps are the same as in Example 1, called catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com