Roll-over sucker elevator

A lifter and suction cup technology is applied in the field of automatic turning devices for workpieces on conveying lines, which can solve the problems of unsynchronized lifting, moving and turning actions, complex structure, large volume, etc. The effect of fewer types of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

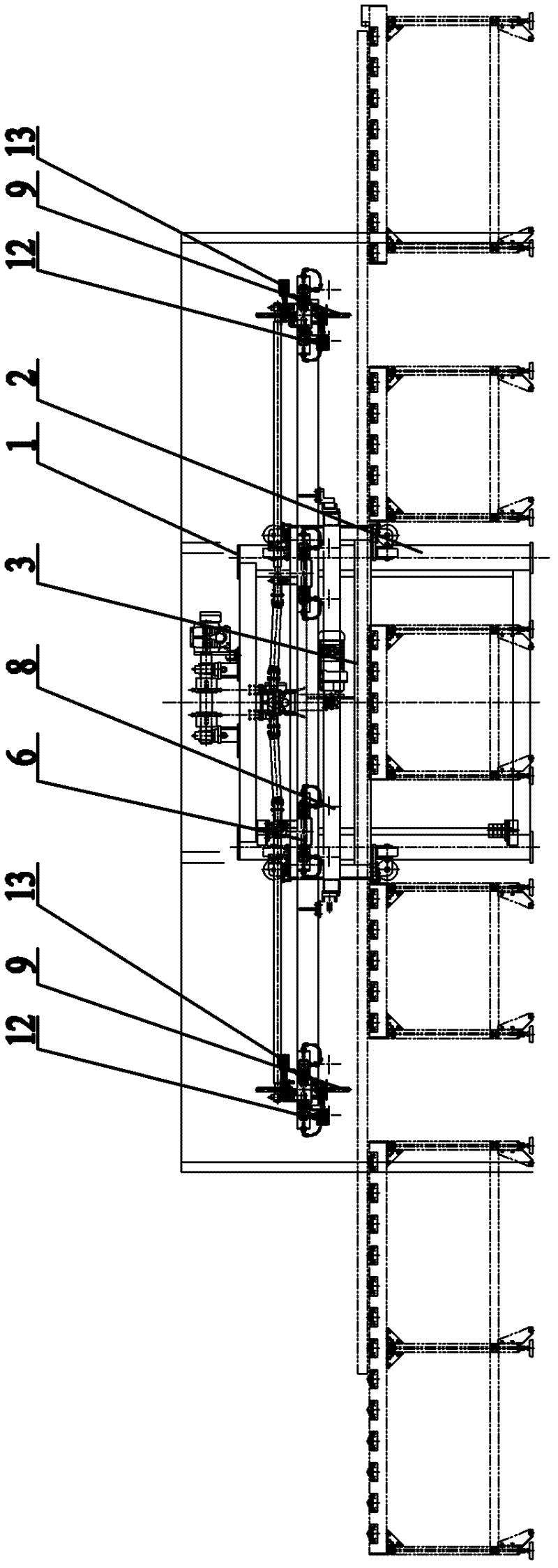

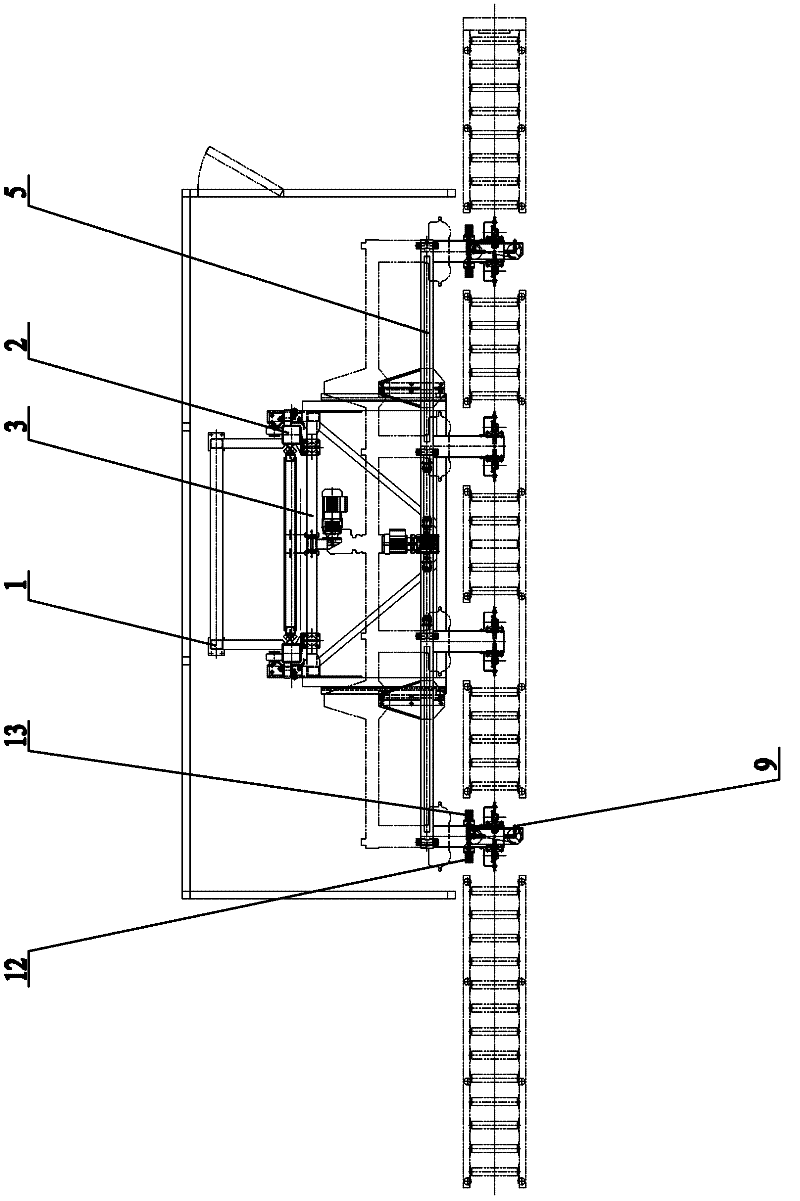

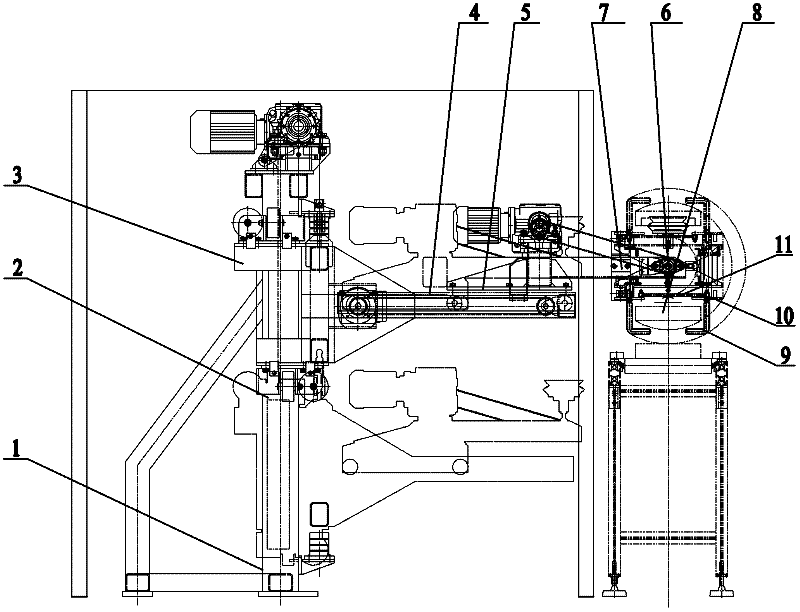

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0013] As shown in the figure: the vertical guide rail 2 is fixed on the column 1, the lifting carriage 3 is slidably connected to the vertical guide rail 2, and the horizontal guide rails arranged horizontally in the left and right directions are fixed on the lifting carriage 3 4. A transverse carriage 5 is slidably connected to the transverse guide rail 4, and the turning frame on the transverse carriage 5 is provided with a turning shaft 6 arranged horizontally in the inner and outer directions. Suction cup 8 is provided.

[0014] Rotate the anti-drop bar 9 that is positioned at both ends sucker 8 both inside and outside of head and tail and be installed with the anti-drop bar 9 of vertical bending shape, be fixed with rotating push plate 10 on the anti-drop bar 9, one end of a connecting rod 11 is fixed on On one of the anti-drop bars 9, the other end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com