Novel rubber-tyred mobile ship-loader

A tire type, ship loader technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of difficulty in emptying the ship loading equipment, poor loading and unloading capacity of the ship loader, and large impact on port operation, so as to improve the operation capacity, The effect of improving utilization and improving loading speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

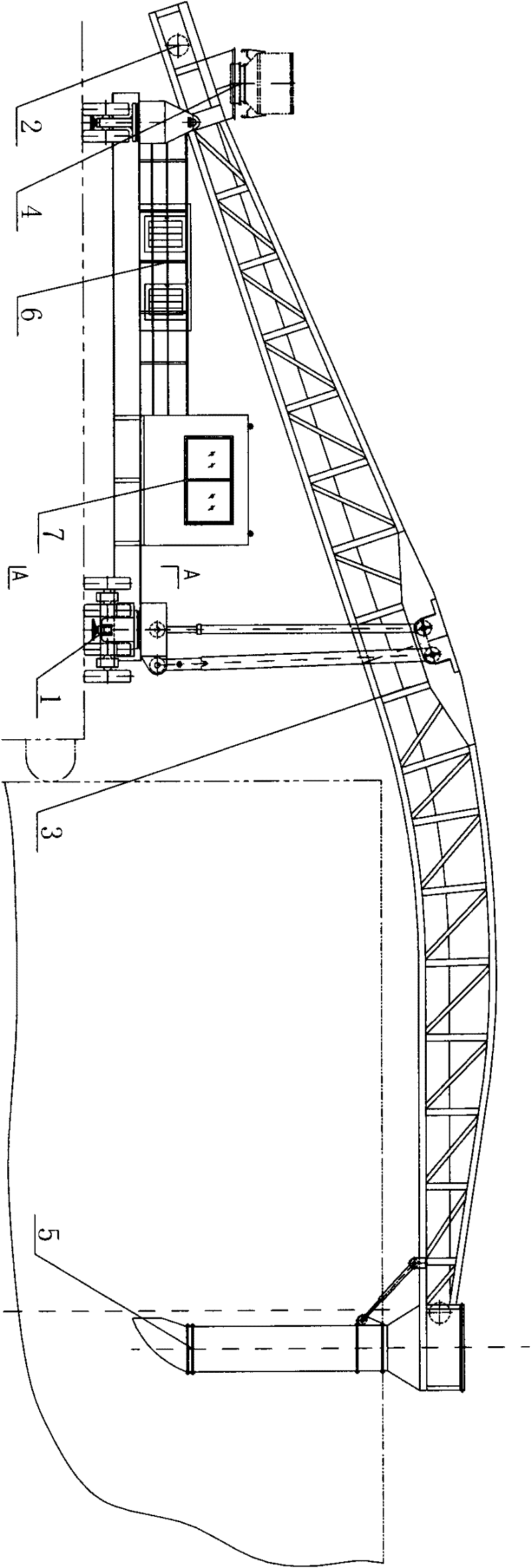

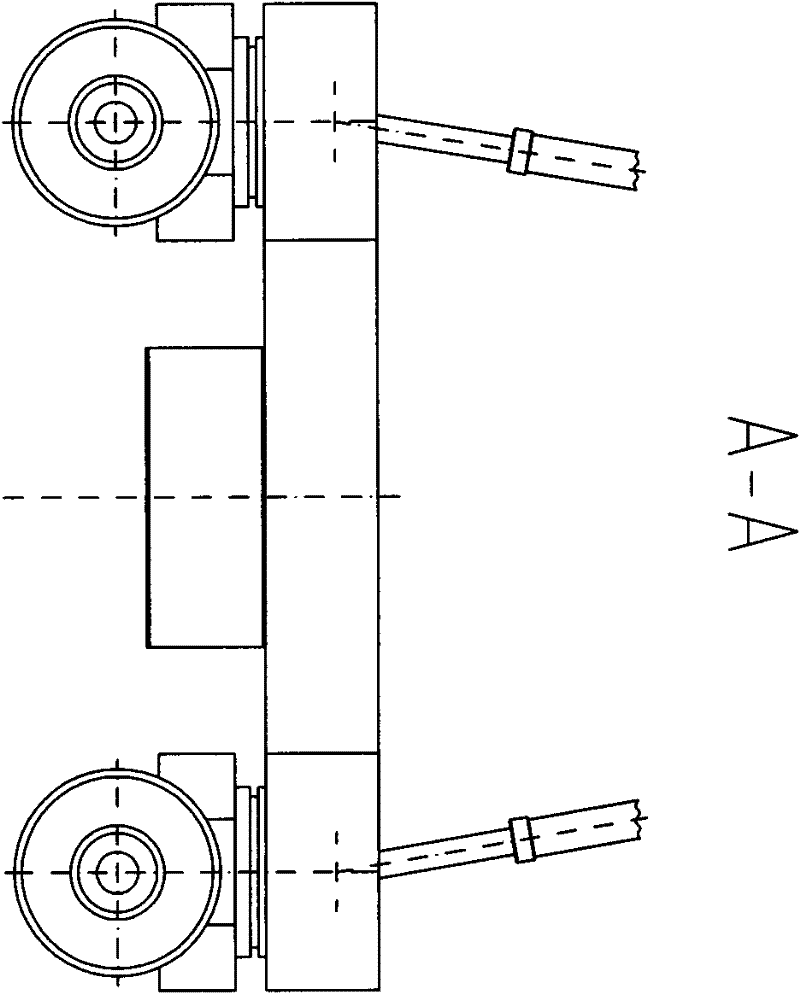

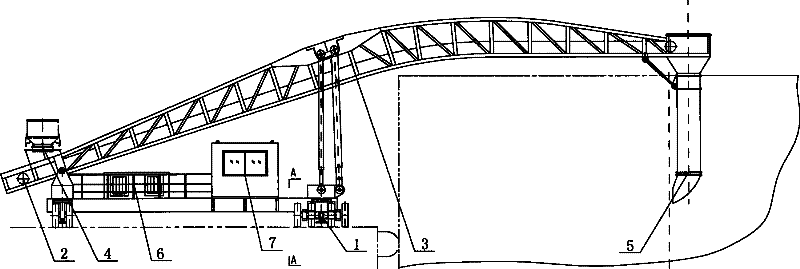

[0015] refer to Figure 1-2 , the specific embodiment adopts the following technical solutions: it includes a traveling mechanism 1, a belt conveyor system 2, a boom pitching mechanism 3, a feeding device 4, a discharge cylinder system 5, a hydraulic control / hydraulic station 6 and an electrical equipment 7, and the walking The left end of the mechanism 1 is connected to the front end of the belt conveyor system 2, the right end of the traveling mechanism 1 is connected to the middle part of the belt conveyor system 2, the upper part of the front end of the belt conveyor system 2 is provided with a feeding device 4, and the end of the belt conveyor system 2 is provided with a discharge cylinder system 5 , the traveling mechanism 1 is provided with a hydraulic control / hydraulic station 6 and electrical equipment 7 .

[0016] Described walking mechanism 1 adopts self-propelled drive, and tire, axle and bearing and hydraulic motor etc. form driving device, and wheel adopts heavy-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com