Washing control method of full-automatic impeller washing machine

The technology of a pulsator washing machine and a control method is applied in the control of effectively washing clothes and cleaning the washing environment, and in the field of washing control of a fully automatic pulsator washing machine, which can solve the problems of damage to mechanical properties, rough rotation speed, waste of electricity, etc. The effect of eliminating the accumulation of dirt, protecting the mechanical properties and improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

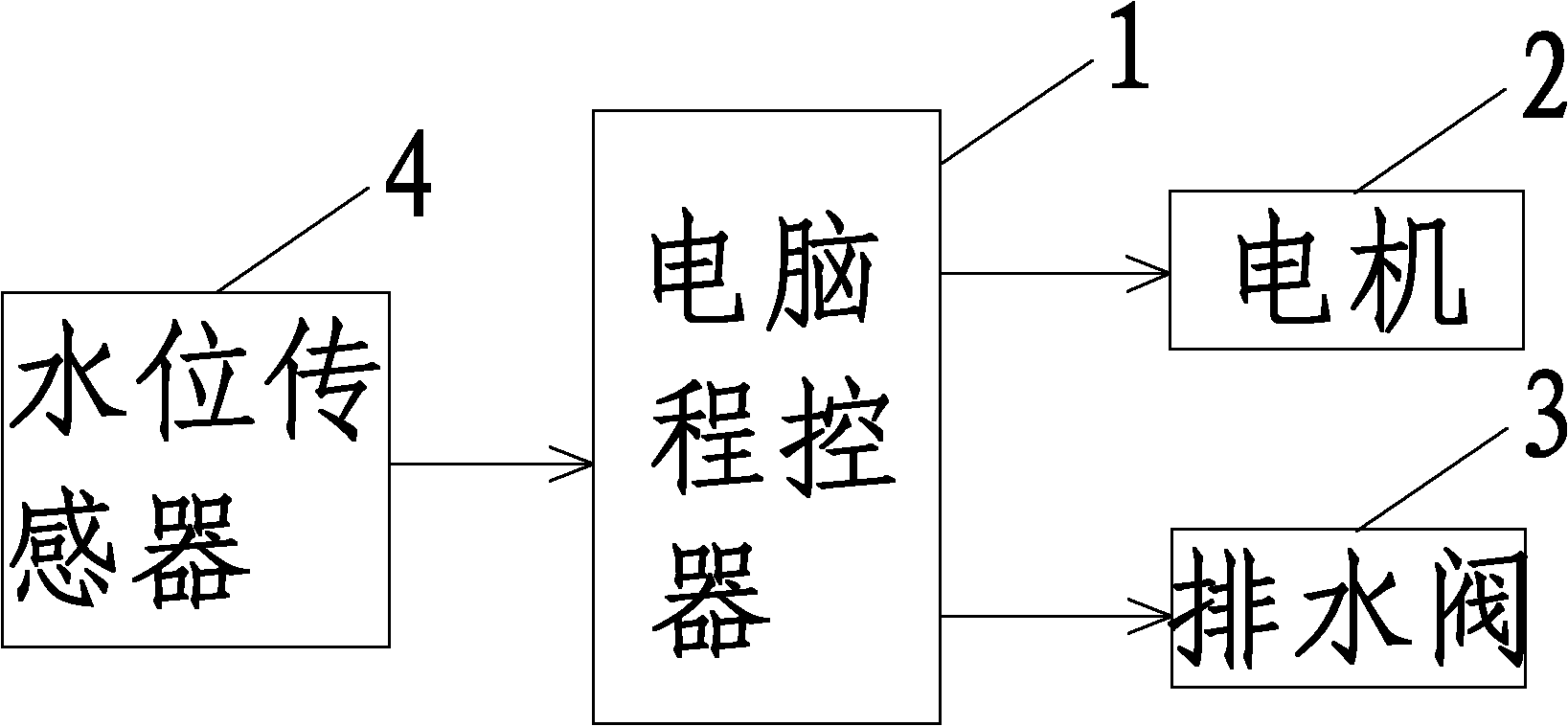

[0030] Such as figure 1 As shown, the fully automatic pulsator washing machine includes an inner tub, an outer tub, and a computer program controller 1. The computer program controller 1 is connected with a motor 2, a drain valve 3 and a water level sensor 4, and the current detection information of the motor 2 and the rotor position detection information Feedback to the computer program controller 1, the speed of the motor 1 is controlled by the computer program controller 1, the water level sensor 4 feeds back the detected water level information to the computer program controller 1, and the computer program controller 1 can control the opening and closing of the drain valve.

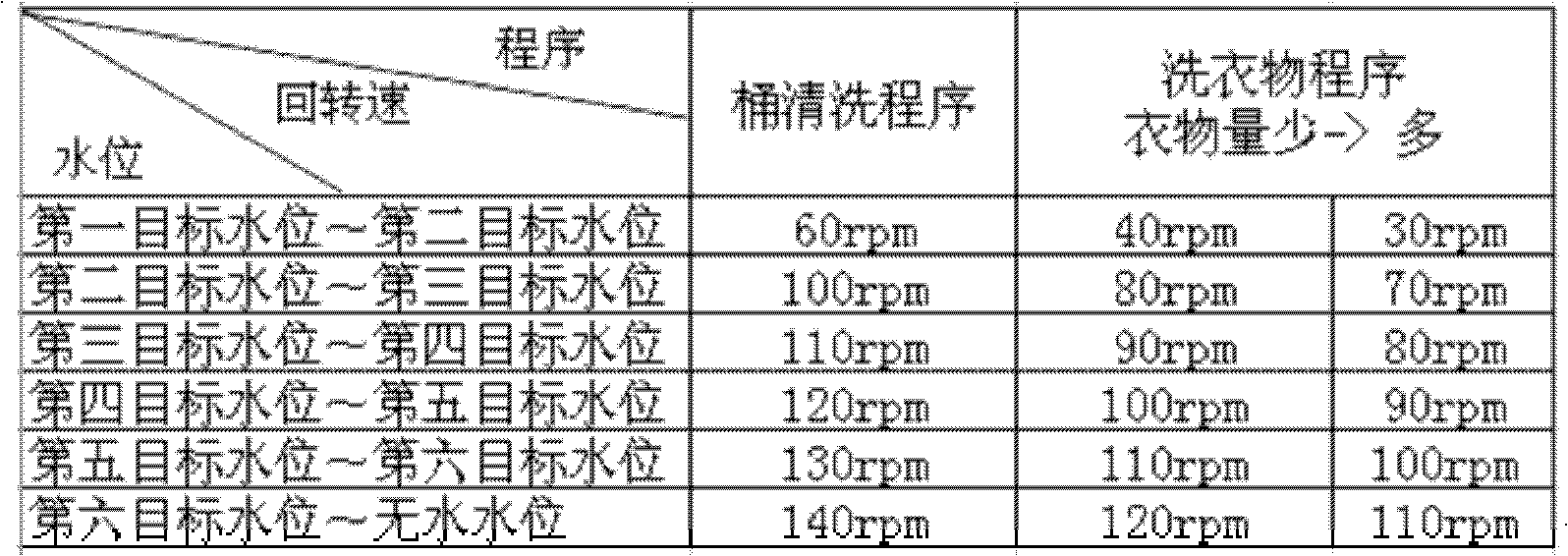

[0031] Such as figure 2 As shown, the cleaning control method of the fully automatic pulsator washing machine includes the following steps in sequence:

[0032] a. The computer program controller first judges whether it is a drainage project, if it is not a drainage project, it will end; if it is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com