straddle vehicle

A straddle-type vehicle and body technology, which is applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of vehicle width enlargement and enlargement, and achieve the effect of improving rideability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

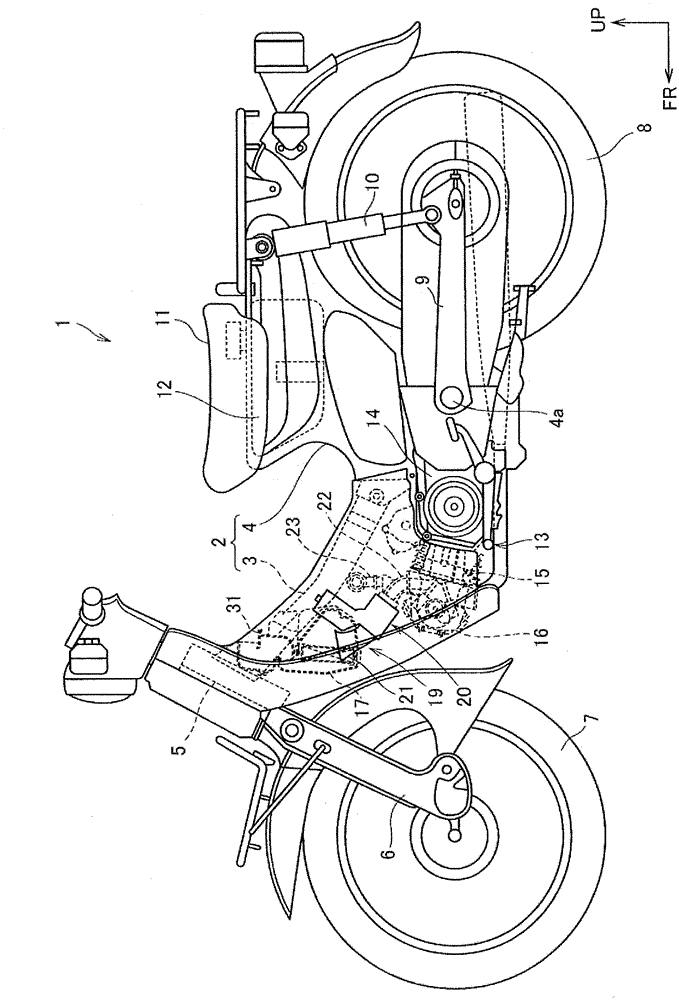

[0072] figure 1 It is a left side view showing the overall configuration of a motorcycle (a saddled vehicle) 1 to which the first embodiment of the present invention is applied. Such as figure 1 As shown, the motorcycle 1 of the present embodiment has a body frame 2 composed of a main frame 3 and a rear frame 4 . The main frame 3 is joined to the rear side of the head pipe 5 by welding, and extends obliquely from the head pipe 5 toward the rear and downward. The rear frame 4 is joined to the rear end of the main frame 3 by welding. The main frame 3 and the rear frame 4 are formed of steel pipes. The main frame 3 may be formed in a shape such as a substantially circular cross section, an I-shape, or a U-shape opening downward. The main frame 3 can also be formed using an aluminum casting or the like.

[0073] A left and right pair of front forks 6 are installed below the head pipe 5, and the front forks 6 can steer freely. Front fork 6 pivotally supports front wheel 7 and...

no. 2 approach

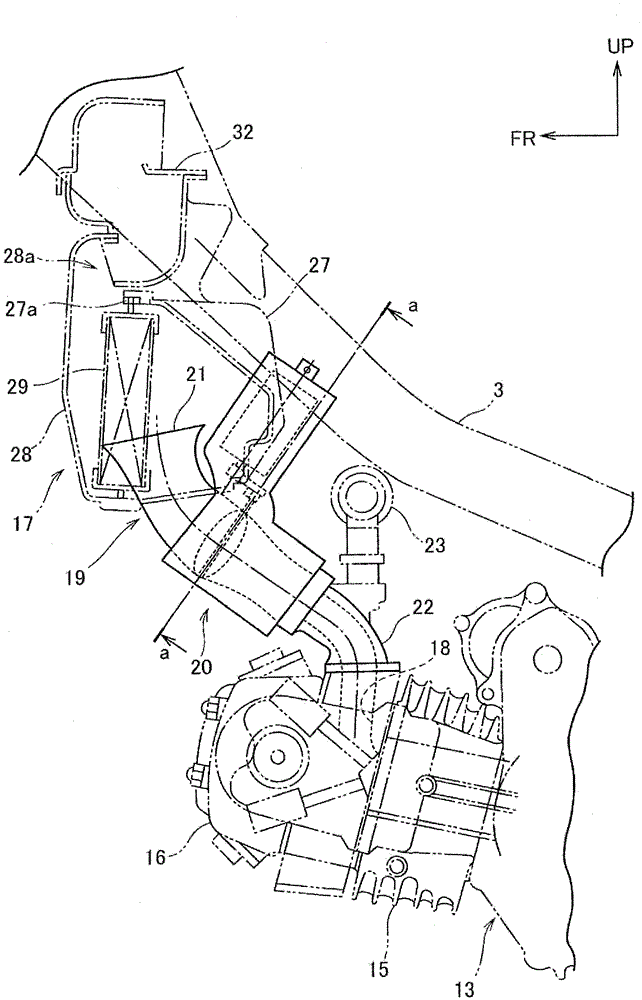

[0097] Below, refer to Figure 4 , Figure 5 A second embodiment will be described. Figure 4 It is a left side view of the periphery of the engine 13 of the motorcycle 1 in the second embodiment. The overall structure of the motorcycle 1 in this second embodiment is the same as that of the first embodiment, and the same reference numerals are assigned to the same components as those of the first embodiment, and description thereof will be appropriately omitted.

[0098] In the first embodiment, the throttle unit 20 is configured to be supported by the main frame 3 , but in the second embodiment, the throttle unit 20A is configured to be supported by the intake chamber 17 . In addition, the internal structure of the throttle unit 20A is the same as that of the throttle unit 20 of the first embodiment, and description thereof will be omitted.

[0099] The throttle valve unit 20A is arranged so as to overlap with the intake chamber 17 in a side view. The air intake chamber 1...

no. 3 approach

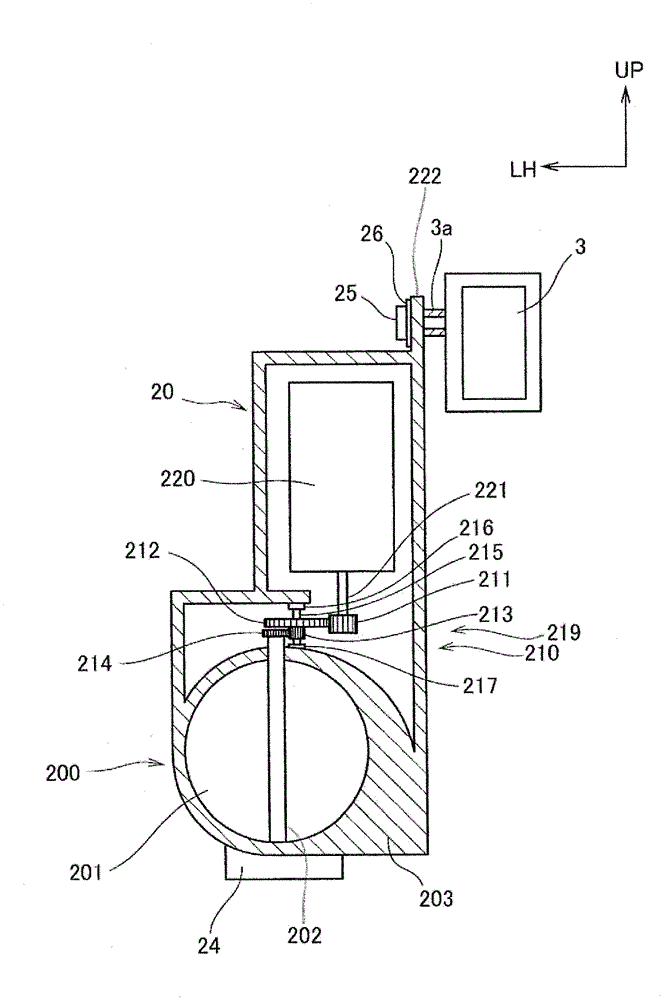

[0106] Below, refer to Figure 6 , Figure 7 A third embodiment will be described. Figure 6 It is a left side view of the periphery of the engine 13 of the motorcycle 1 in the third embodiment. In the first embodiment, the air intake chamber 17 is disposed behind the head pipe 5 and below the main frame 3 , but in this third embodiment, the air intake chamber 117 is disposed in front of the head pipe 5 . Structure. According to this structure, by arranging the intake chamber 117 in front of the head pipe 5, the distance between the intake chamber 117 and the throttle body 200 can be separated, and the connection pipe 121 connecting the intake chamber 117 and the throttle body 200 can be made The length of the suction pipe becomes longer, so that the low-speed torque can be increased.

[0107] In this third embodiment, the overall configuration of the motorcycle 1 is the same as that of the first embodiment except for the arrangement configuration of the air intake chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com