Metal wire clip of tail end fixing cable

A technology for fixing cables and metal wires, which is applied in the direction of devices for relieving stress at wire connections, components of connection devices, coupling devices, etc., and can solve the problem of reliability, cable crimping, and airtightness affecting electromagnetic interference shielding effect, model Diversification affects management costs, poor electromagnetic interference shielding effect, etc., to achieve the effect of solving electromagnetic interference shielding problems, convenient shielding layer grounding, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

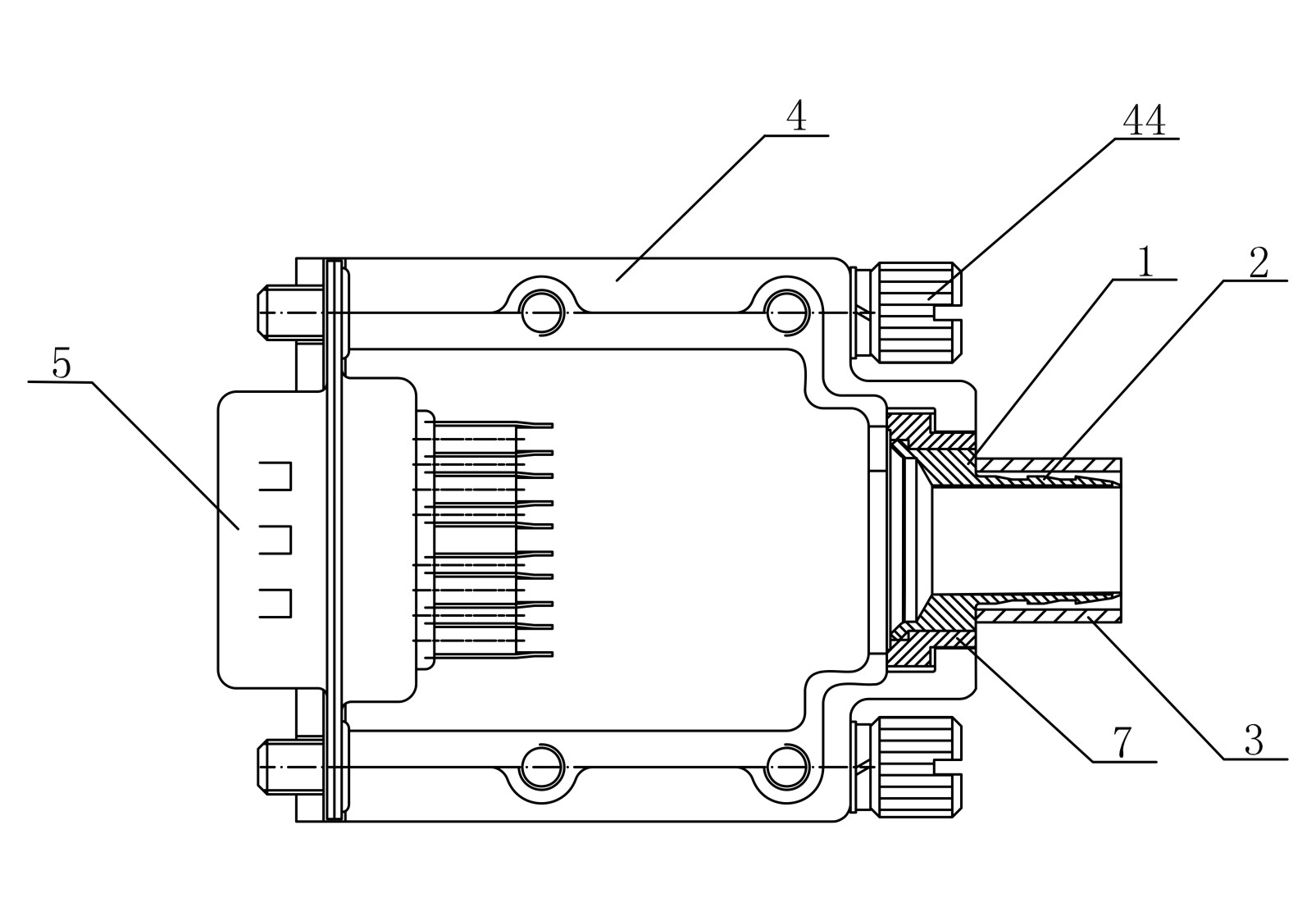

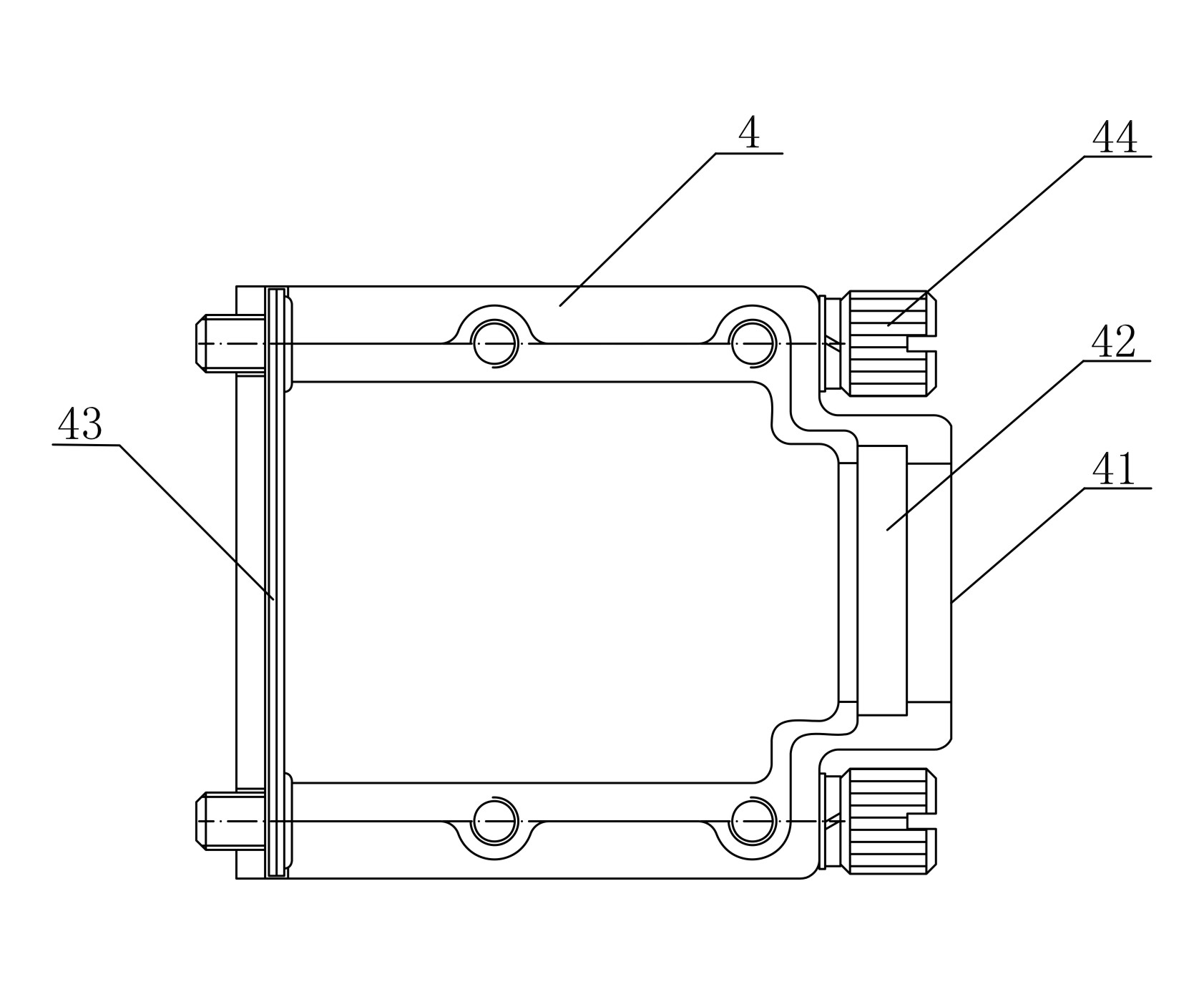

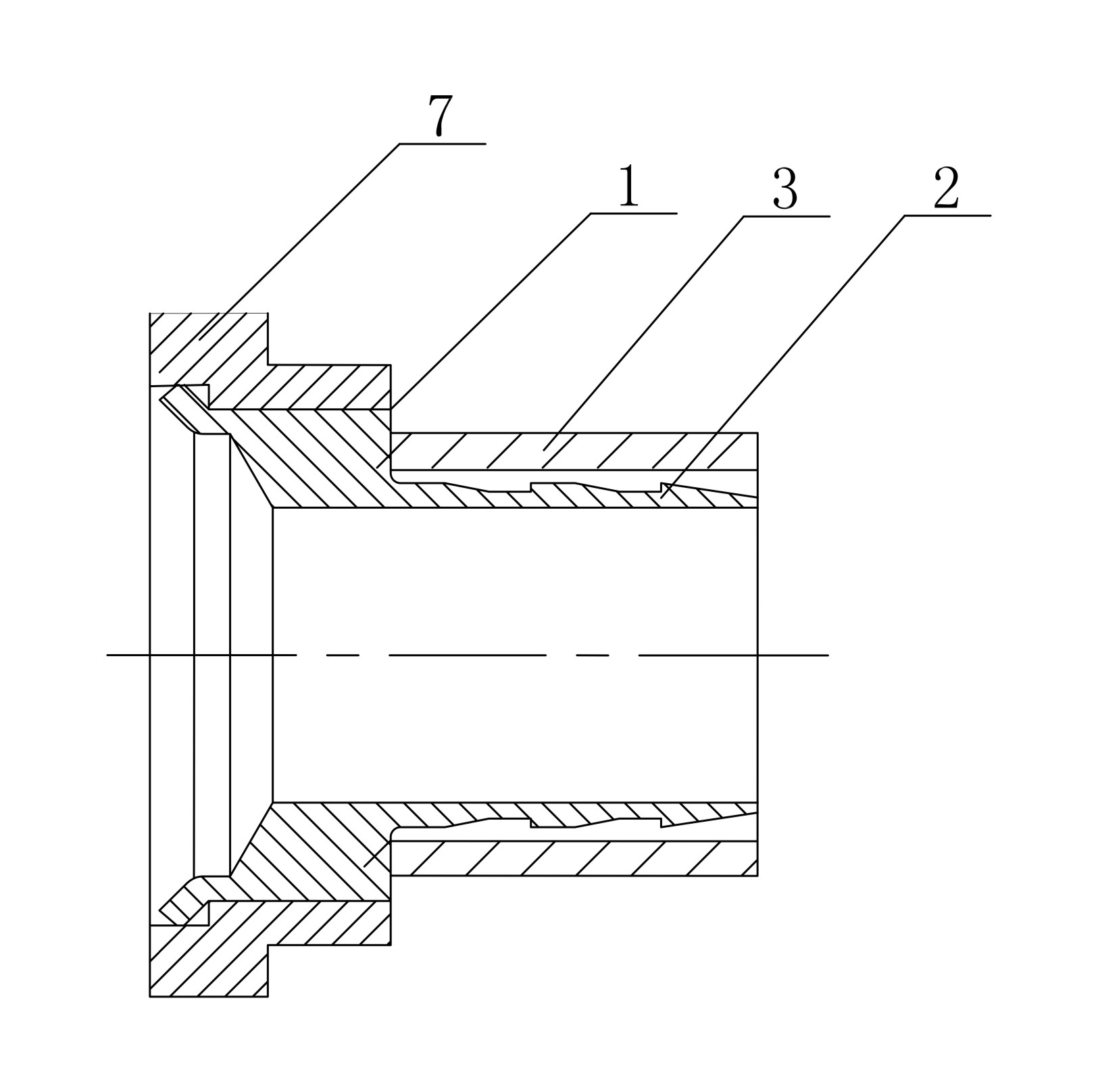

[0018] See attached figure 1 , the present invention is made up of metal wire clamp 4, connector 5 and outlet sleeve 1, and metal wire clamp 4 is the line box that is provided with cable port 41 and connector port 43, and outlet sleeve 1 and connector 5 are respectively arranged on metal On the ports on both sides of the clamp 4. The outlet sleeve 1 is composed of a flange 7, an outlet barrel 2 and a crimping pipe 3. The flange 7 is a rectangular plate with a central through hole 12 and a step 17; the central through hole 12 is symmetrically provided with a flat groove 10, one port is provided with a ring groove 16; the outlet tube 2 is provided with a platform 13 in the middle and a casing with a serrated cylindrical surface 14 and a knurled cylindrical surface 12 at both ends, the platform 13 is symmetrically arranged and has a complementary structure with the flat groove 10; the outlet barrel 2 is set with the flange 7, and the knurled cylindrical surface 12 and the ring g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com