Lid and valve member, toner dispensing system and method

A valve assembly, distribution system technology, applied in chemical instruments and methods, distribution devices, powder material distribution, etc., can solve problems such as poor nozzle sealing, and achieve the effect of high distribution accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

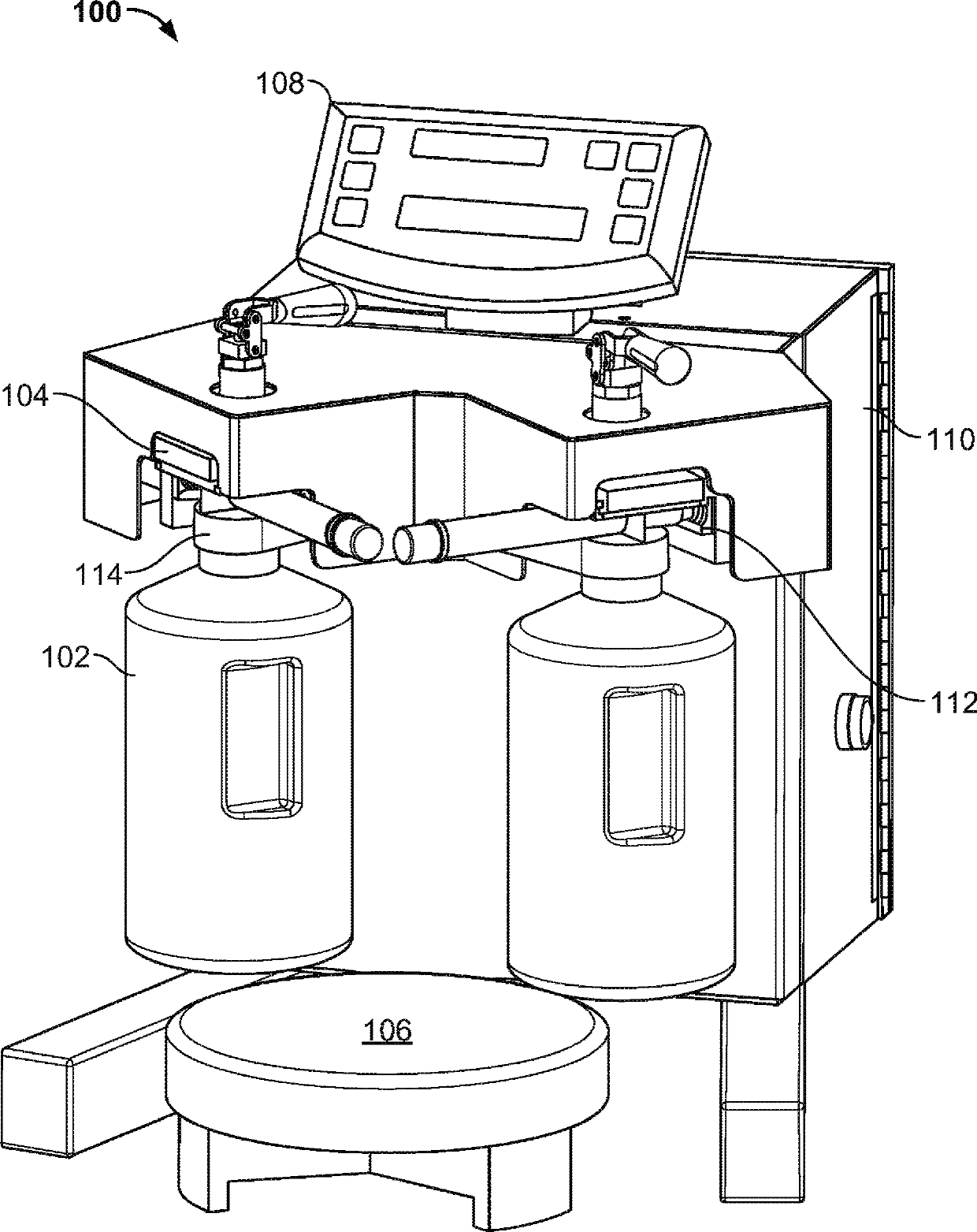

[0030] figure 1 is an isometric view of an example toner dispenser 100 . Toner dispenser 100 includes first and second toner containers 102 , first and second cap and valve assemblies 104 , scale 106 , optional scale control interface 108 , and housing 110 .

[0031] Each toner container 102 holds a volume of a corresponding toner (eg, a corresponding paint color). The toner container 102 may have different sizes depending on the application (eg, half liter, one liter, or two liter container volume). Larger sized containers can be stored remotely and the contents of the larger container can be dispensed using the cap and valve assembly 104 through the use of adapters and tubing.

[0032]Each of the toner containers 102 is coupled to a corresponding cap and valve assembly 104 using a cap 114 . Each cap and valve assembly 104 couples a respective toner container 102 to a horseshoe coupling 112 to allow dispensing of a particular toner. In some implementations, each valve ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com