3D-trench electrode detectors

A radiation detector and electrode technology, which is applied in the field of radiation detectors, can solve problems such as high depletion voltage, charge sharing, and unfavorable detectors, so as to minimize the concentration of highly uneven electric fields and overcome the existence of highly uneven electric fields , the effect of improving the energy resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

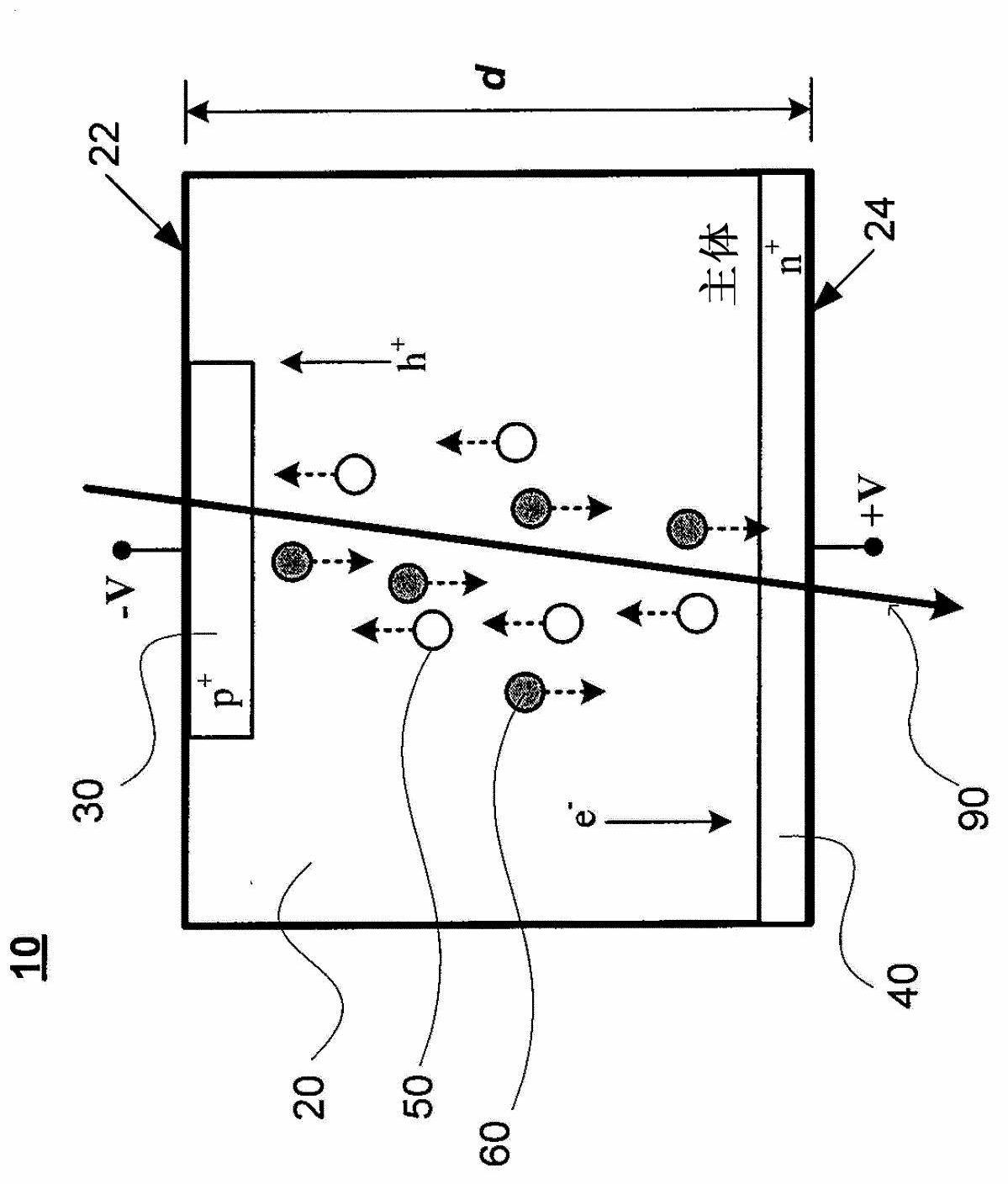

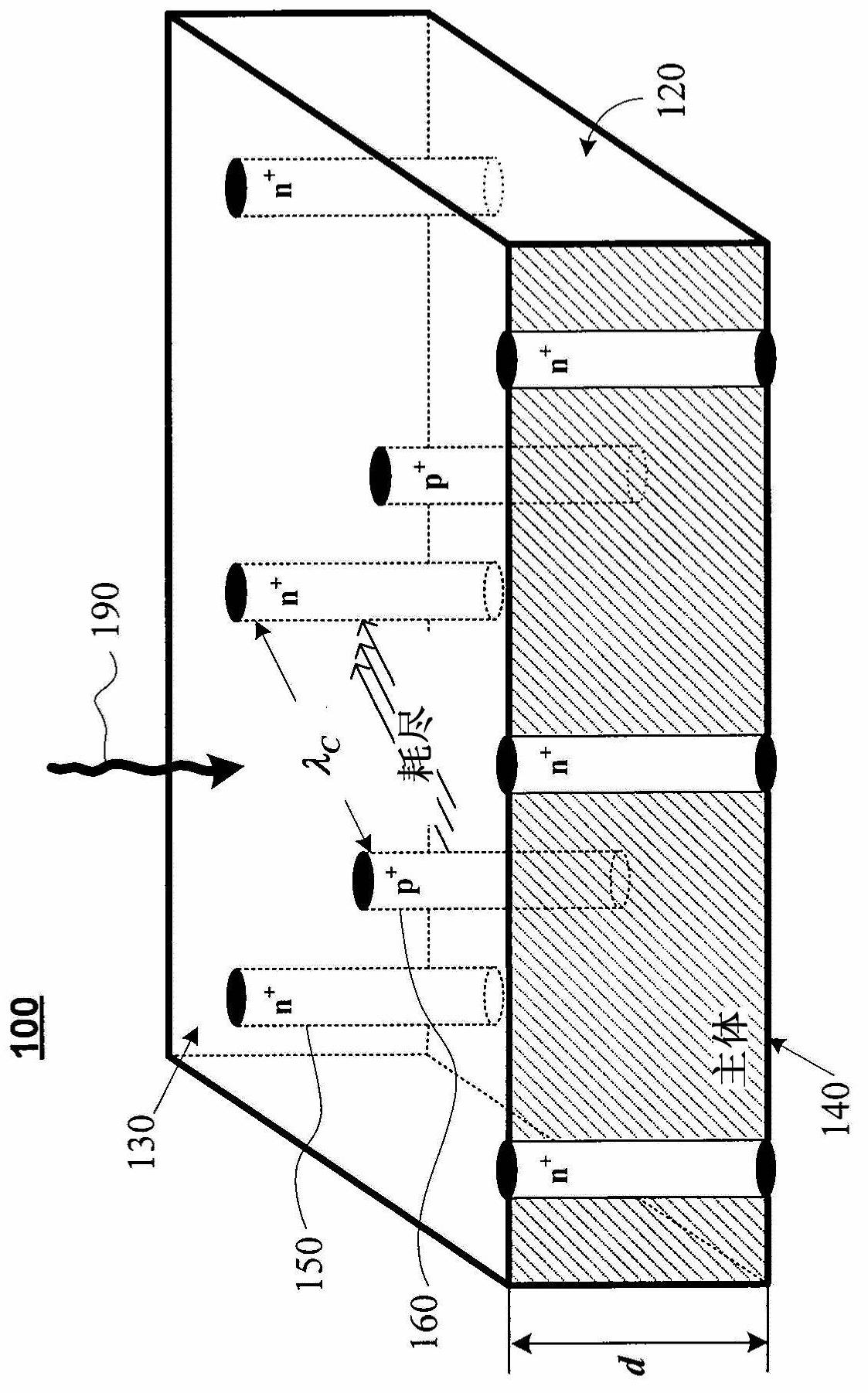

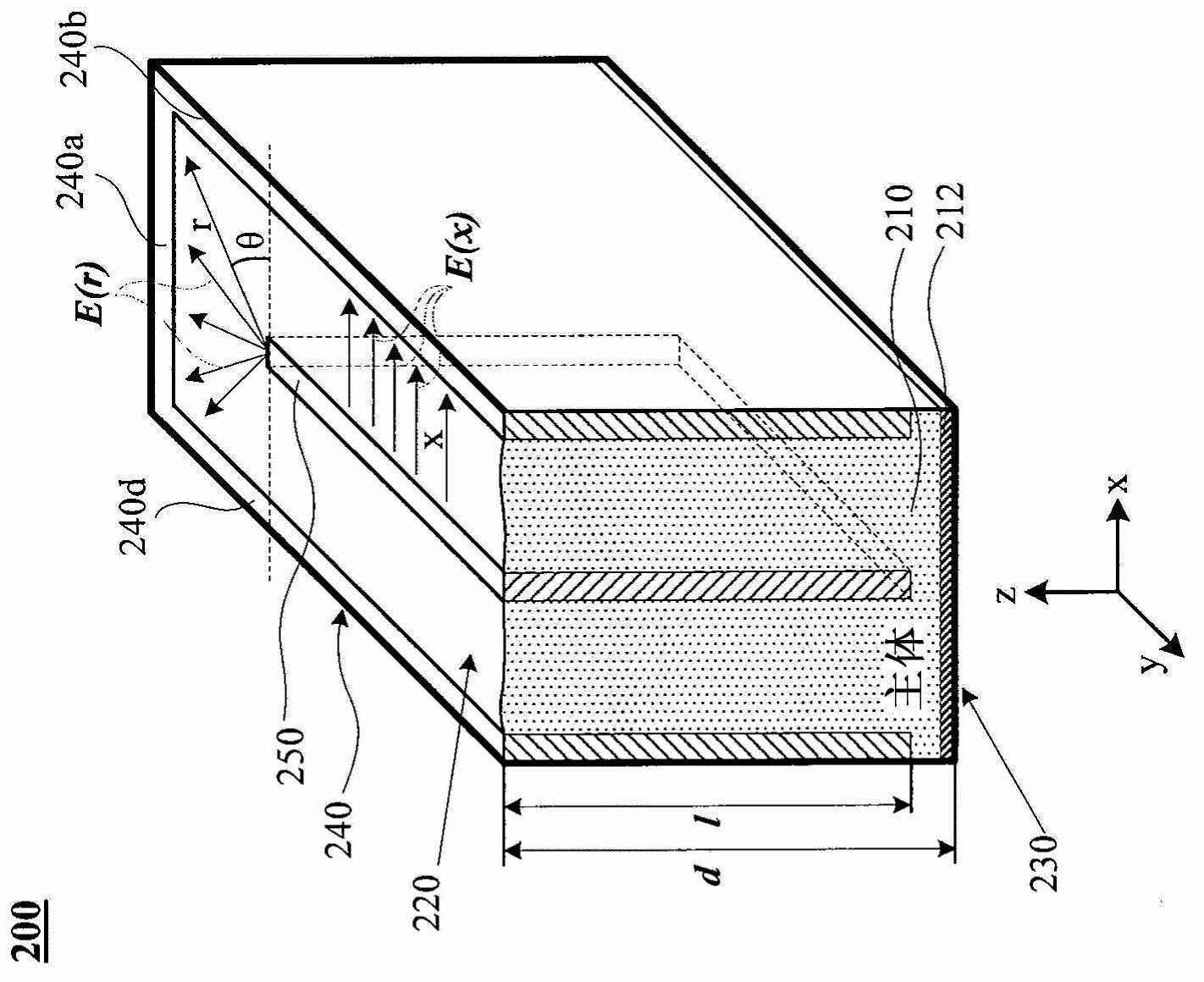

[0072] To avoid misunderstandings with other 3D technologies and detectors in nomenclature and structure (i.e., 3D stacking of detectors and electronics and 3D position-sensitive detectors), with respect to the above-mentioned conventional "3D detectors" shown in Fig. 1B, The 3D detector of the present invention is called a "3D trench electrode detector". In particular, several embodiments of new and novel 3D detectors are disclosed based on a first electrode configuration fabricated in the form of a "trench" surrounding a second electrode in the form of a rod or pillar. As used in this specification, the term "groove" generally means a deep and narrow groove or cutout having a predetermined width and depth. Therefore, this new type of 3D detector is often described as a "3D trench electrode detector", but for simplicity and brevity, the 3D trench electrode detector can also be referred to interchangeably as a "3D trench electrode detector". For the convenience of the reader,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com