Tape application machine and method for applying an electrically non-conductive tape to a battery cell

A non-conductive, battery unit technology, applied in the direction of non-aqueous electrolyte batteries, assembled battery machines, electrolyte battery manufacturing, etc., can solve problems such as current leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

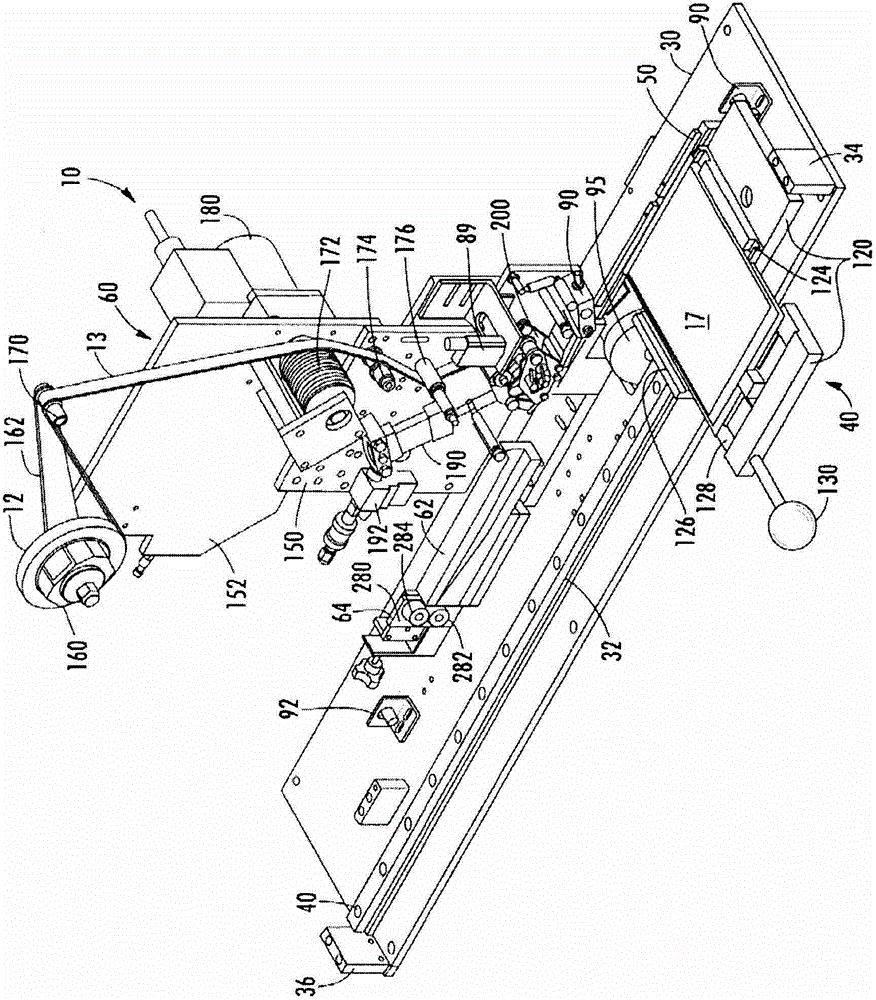

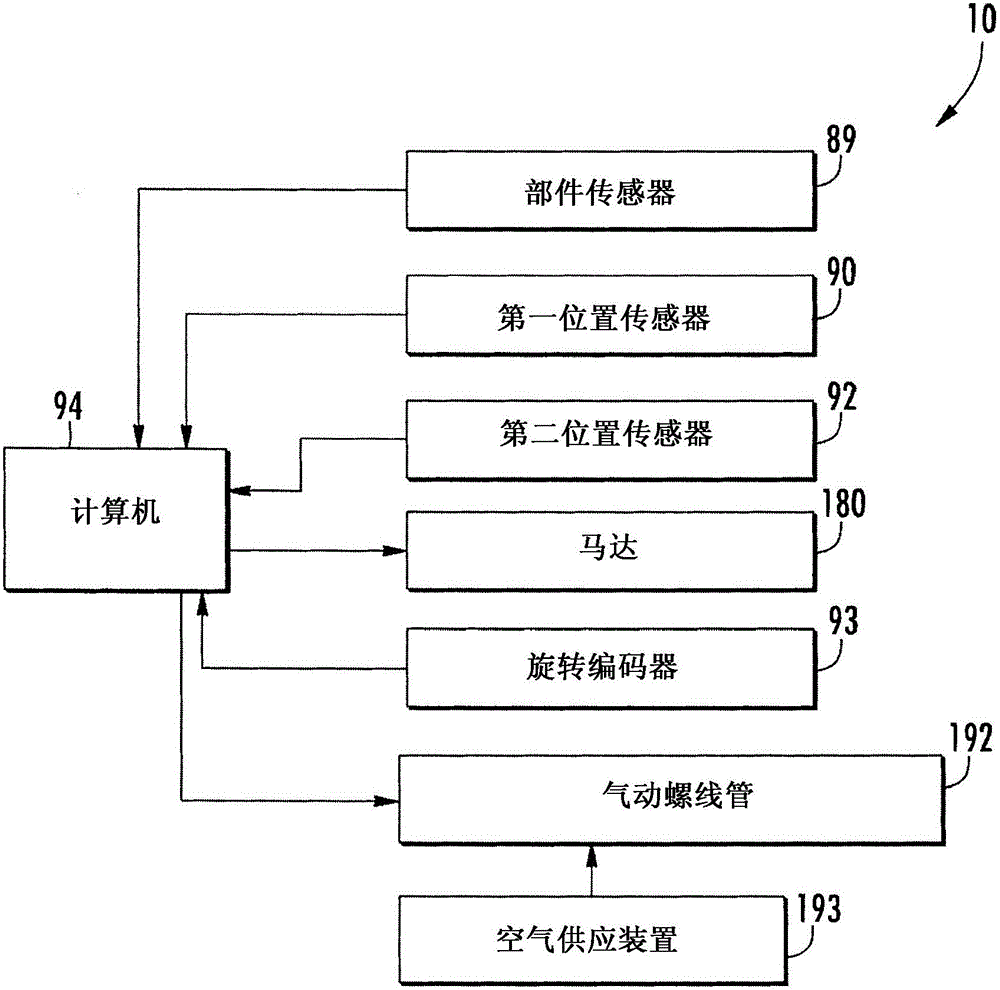

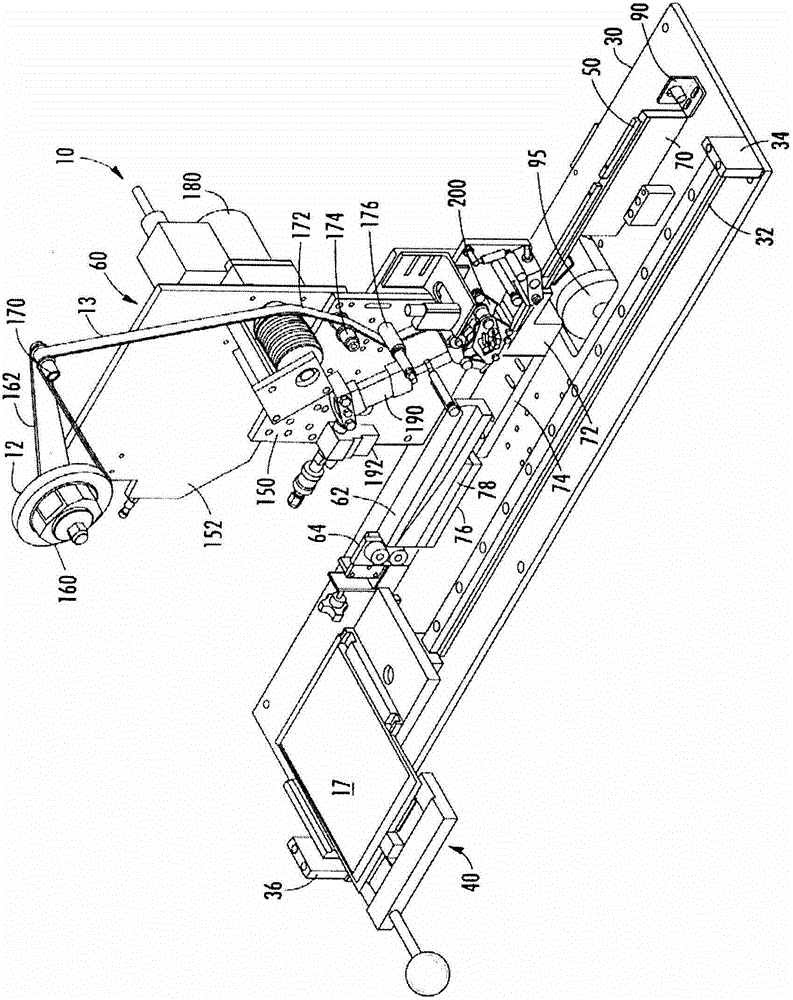

[0021] refer to Figure 1-3 , according to an exemplary embodiment, there is provided an adhesive tape applicator 10 for applying a predetermined length of non-conductive adhesive tape on a battery cell 17 .

[0022] refer to Figure 11 and 12 , the exemplary battery cell 17 has a pouch-shaped body portion 18 , edge portions 19 , 20 , 21 , 22 and electrodes 25 , 26 . Edge portions 19 and 20 extend outwardly from opposite edges of pouch body portion 18 and are arranged substantially parallel to each other. Edge portions 21 , 22 also extend outwardly from opposite edges of the bag-shaped body portion 18 and are arranged substantially parallel to each other and substantially perpendicular to edge portions 19 , 20 . The electrodes 25 , 26 extend outwardly from the edge portion 22 . In one exemplary embodiment, the battery cells 17 are lithium-ion pouch-type battery cells. Of course, in alternative embodiments, other types of battery cells known to those skilled in the art may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com