Compound fermentation method for producing fermented feed

A compound fermentation and fermented feed technology, applied in animal feed, animal feed, application, etc., can solve the problems of limited decomposition effect of macromolecular protein and cellulose, and achieve the effect of low cellulose content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

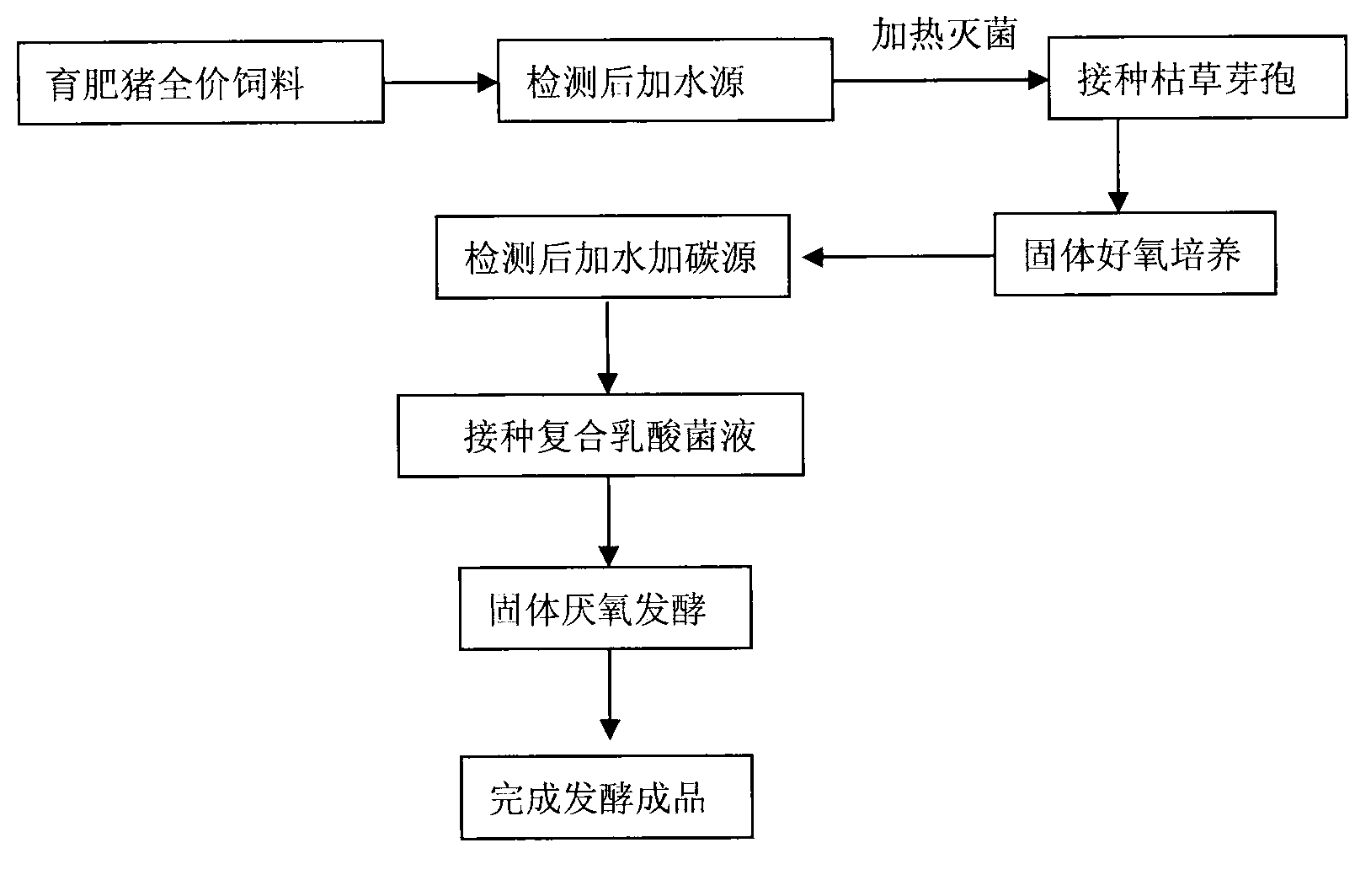

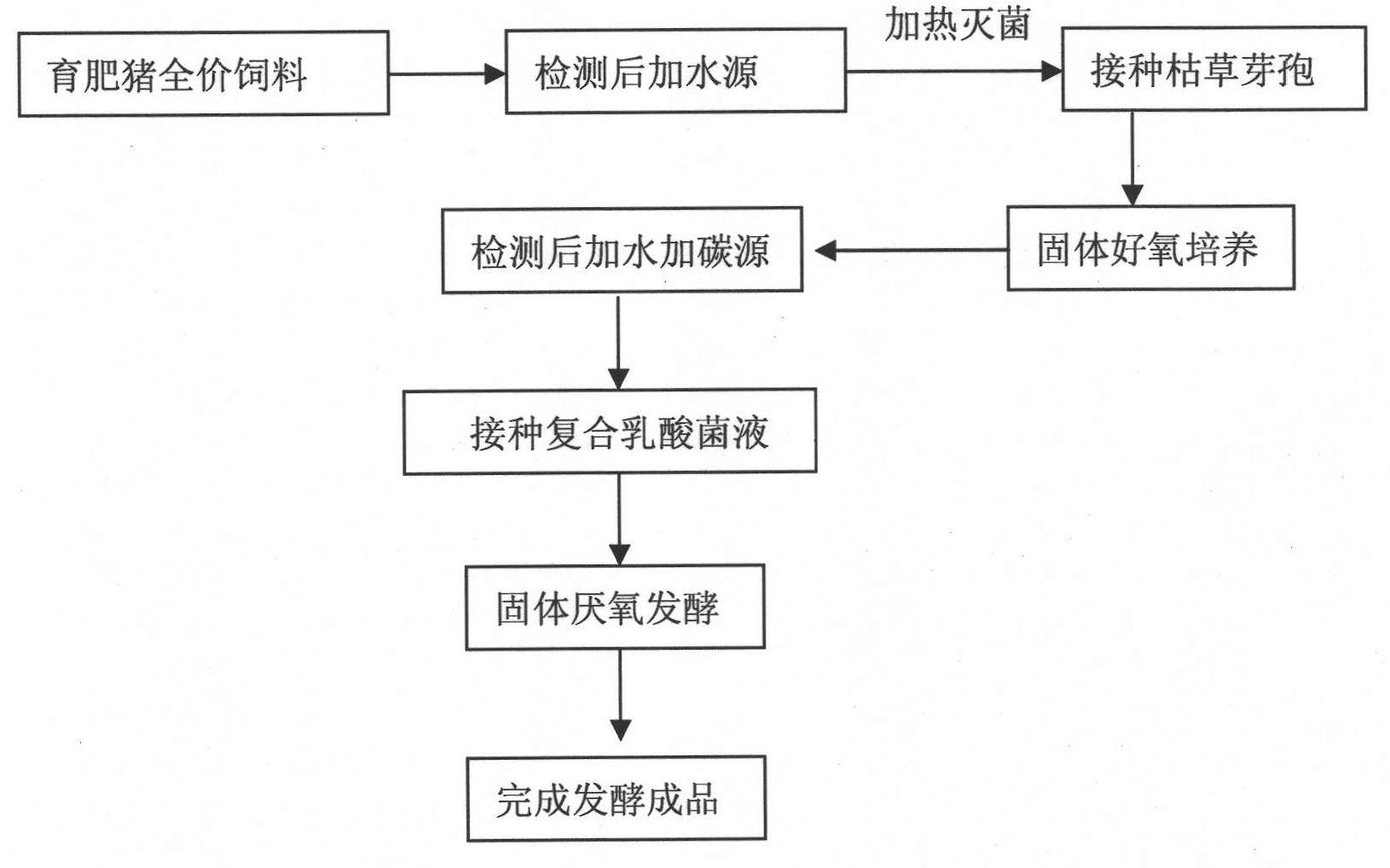

[0014] like figure 1 Shown is the flow chart of the composite fermentation method for producing fermented feed, and the concrete steps of the composite fermentation method for producing fermented feed are as follows:

[0015] 1. Solid aerobic fermentation stage:

[0016] (1) Mix 6kg of corn, 2kg of bean cake, 1.45kg of fine bran, 0.05kg of salt, 0.1kg of fish meal, and 0.4kg of premix (purchased from Shanghai SEG Biotechnology Co., Ltd., fattening pig premix-Dazhubao) , prepare 10kg of full-price feed for fattening pigs. After measuring the moisture according to the national standard, the moisture content of the material is 14wt%, put it into a stainless steel container, add 3.2kg of drinking water, and control the moisture content of the material at 35wt%. The stainless steel container is covered with 6 layers of gauze, heated and sterilized with steam, the sterilization temperature is 120 degrees, the time is 15 minutes, and the temperature is lowered to 35 degrees for stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com