Paper towel and manufacturing method thereof

A manufacturing method and technology of paper towels, which are applied in the direction of chemical instruments and methods, washing composition fragrances, detergent compounding agents, etc., can solve the problems that the effectiveness cannot be guaranteed, and achieve the avoidance of cross-infection, convenient use, and non-irritating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

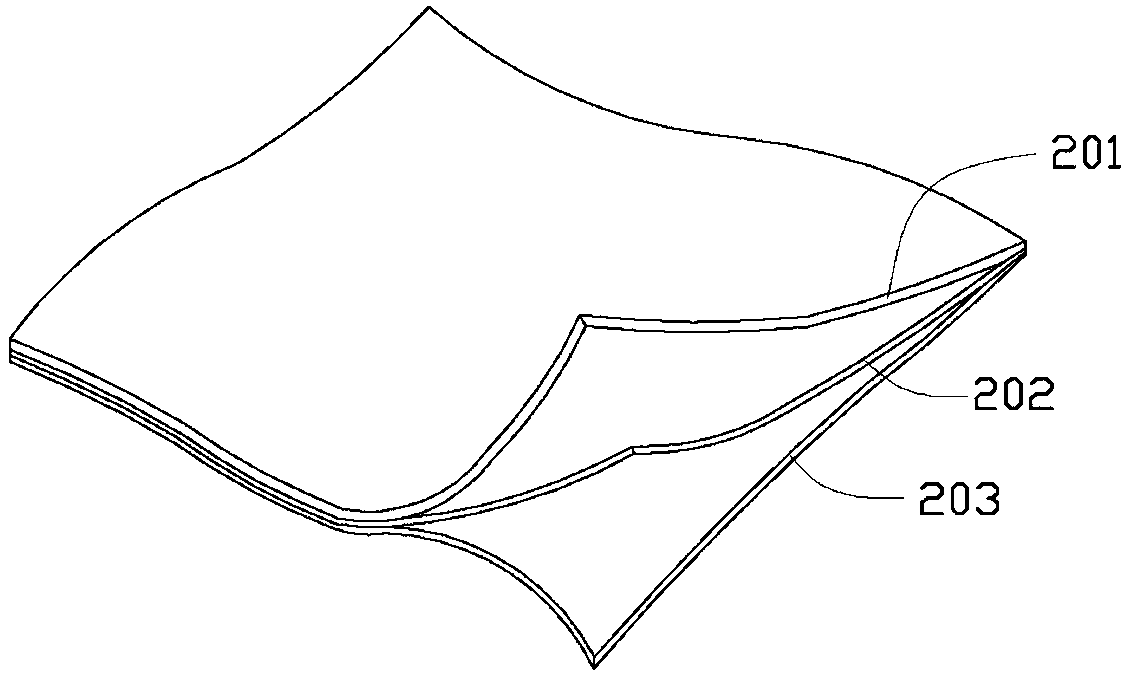

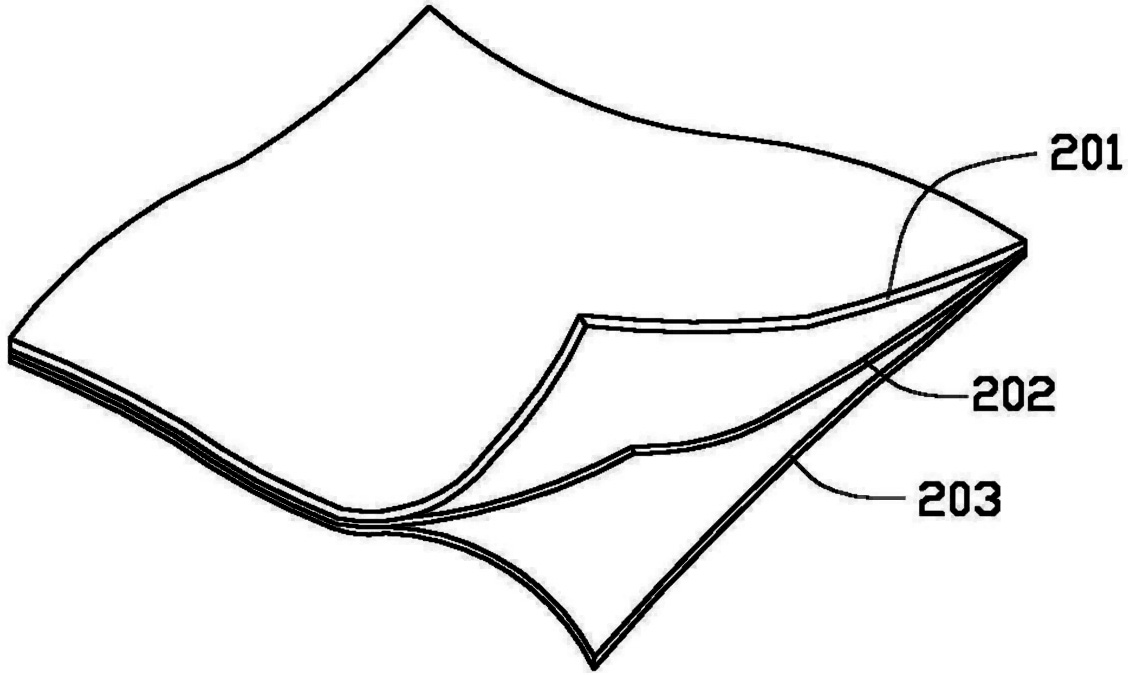

[0017] The tissue of the present invention has at least three layers, including two skin layers located on the outside of the tissue and at least one core layer located on the inside of the tissue.

[0018] The surface layer is made of plant fiber. Plant fibers can be selected from wood pulp fibers, mixed fibers of wood pulp and non-wood pulp, mixed fibers of wood pulp and cotton fibers or chemical fibers. After the surface layer is made of the above-mentioned plant fibers by wet method, it has the following characteristics:

[0019] Basis weight: 15~35g / m 2

[0020] Dry tensile strength: 1.2~2.0N.m / g

[0021] Wet tensile strength: 0.4~0.8N.m / g

[0022] Water absorption: 18~35mm / 100sec

[0023] The stated strength refers to the geometric mean tensile force (GMT) of the paper, and its calculation formula is as follows:

[0024] GMT=

[0025] Among them, MDT indicates the tensile force of the paper layer in the machine direction, and the national standard unit is N.m / g,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com