Automatic control water bath evaporation unit

A unit and water bath technology, applied in the fields of food, chemical industry, and medicine, can solve the problems of increasing concentration and extraction costs, low heat conduction efficiency, and reduction of concentration efficiency, and achieve the effects of shortening concentration time, increasing heat transfer coefficient, and improving concentration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

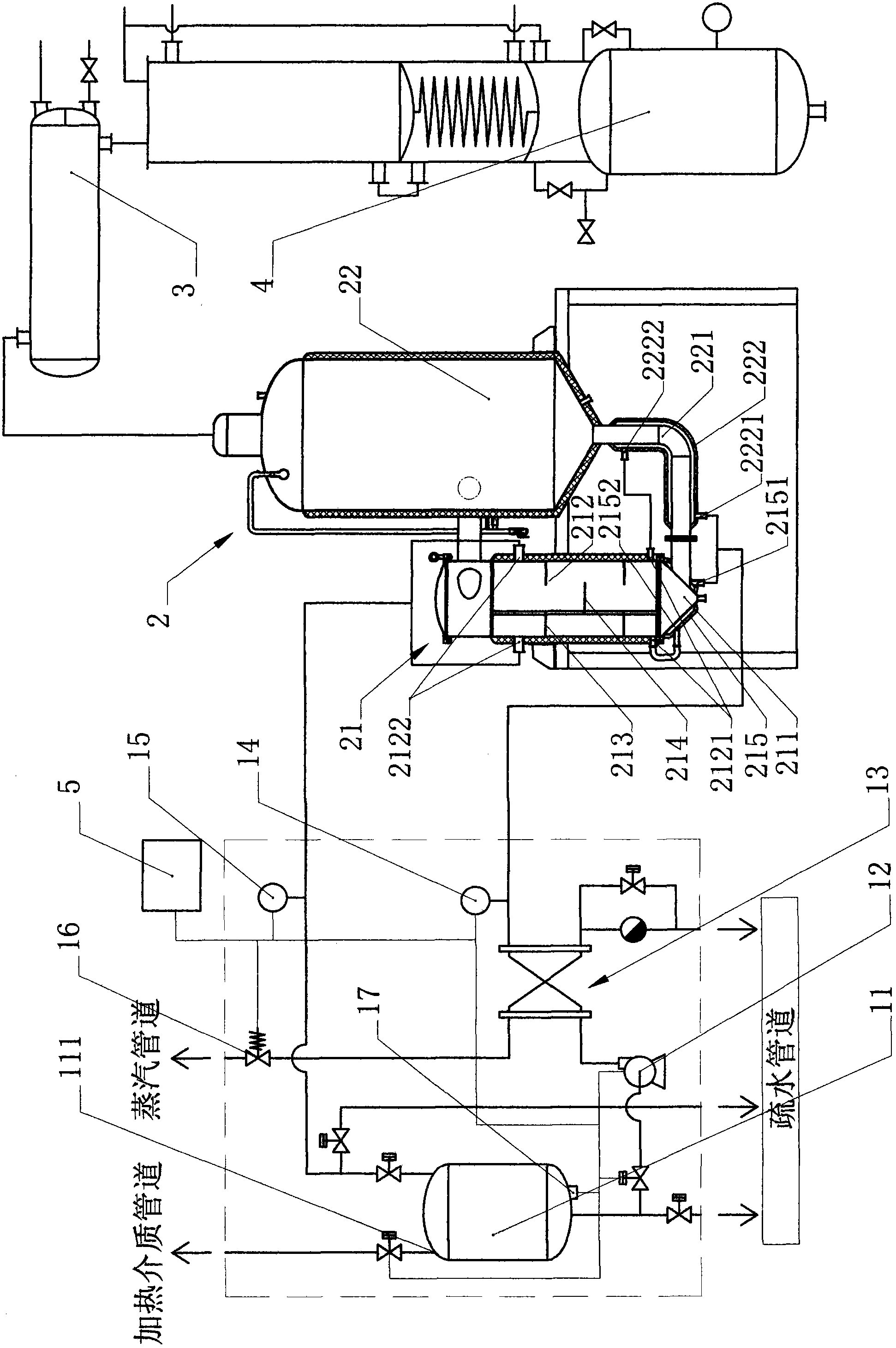

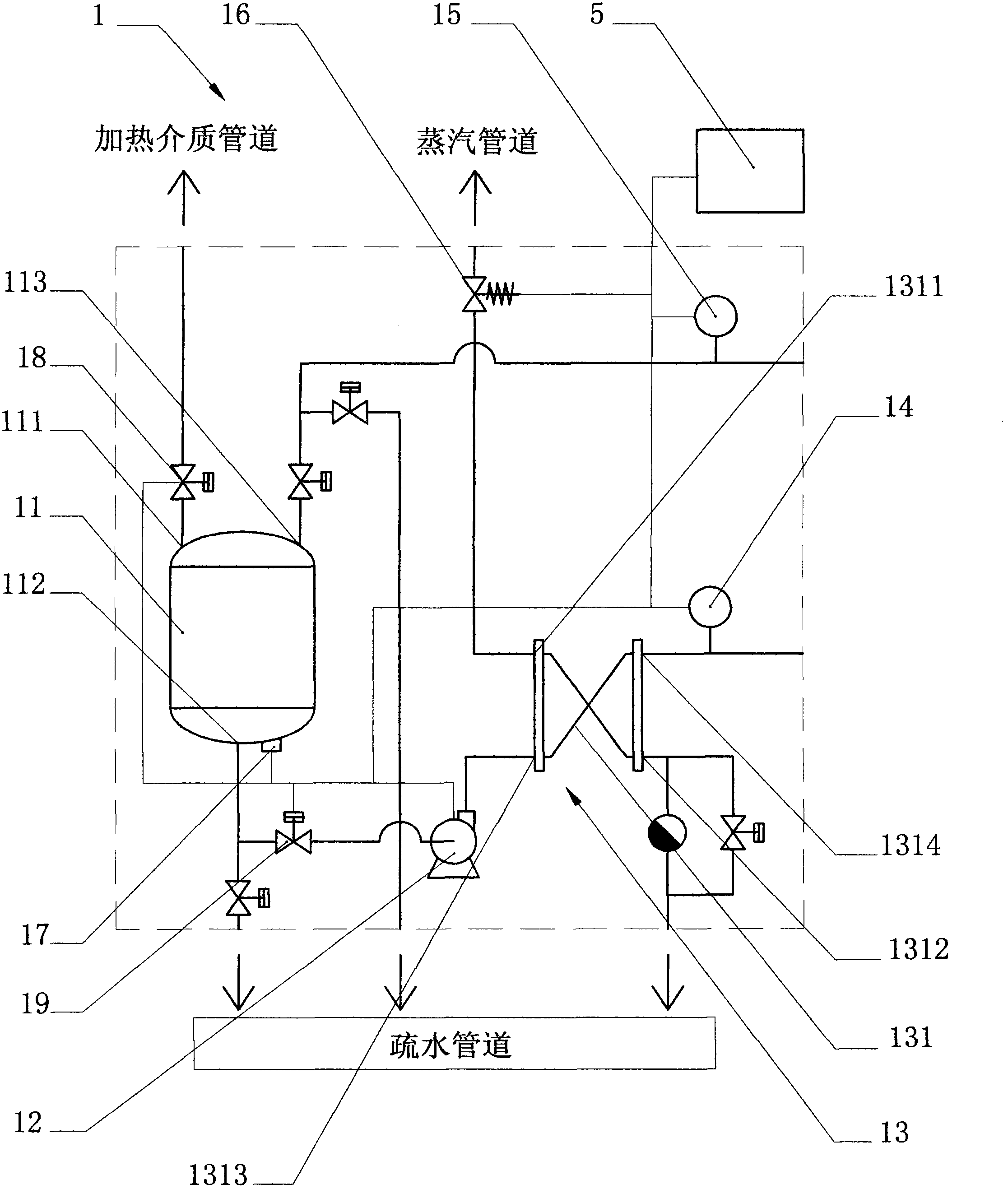

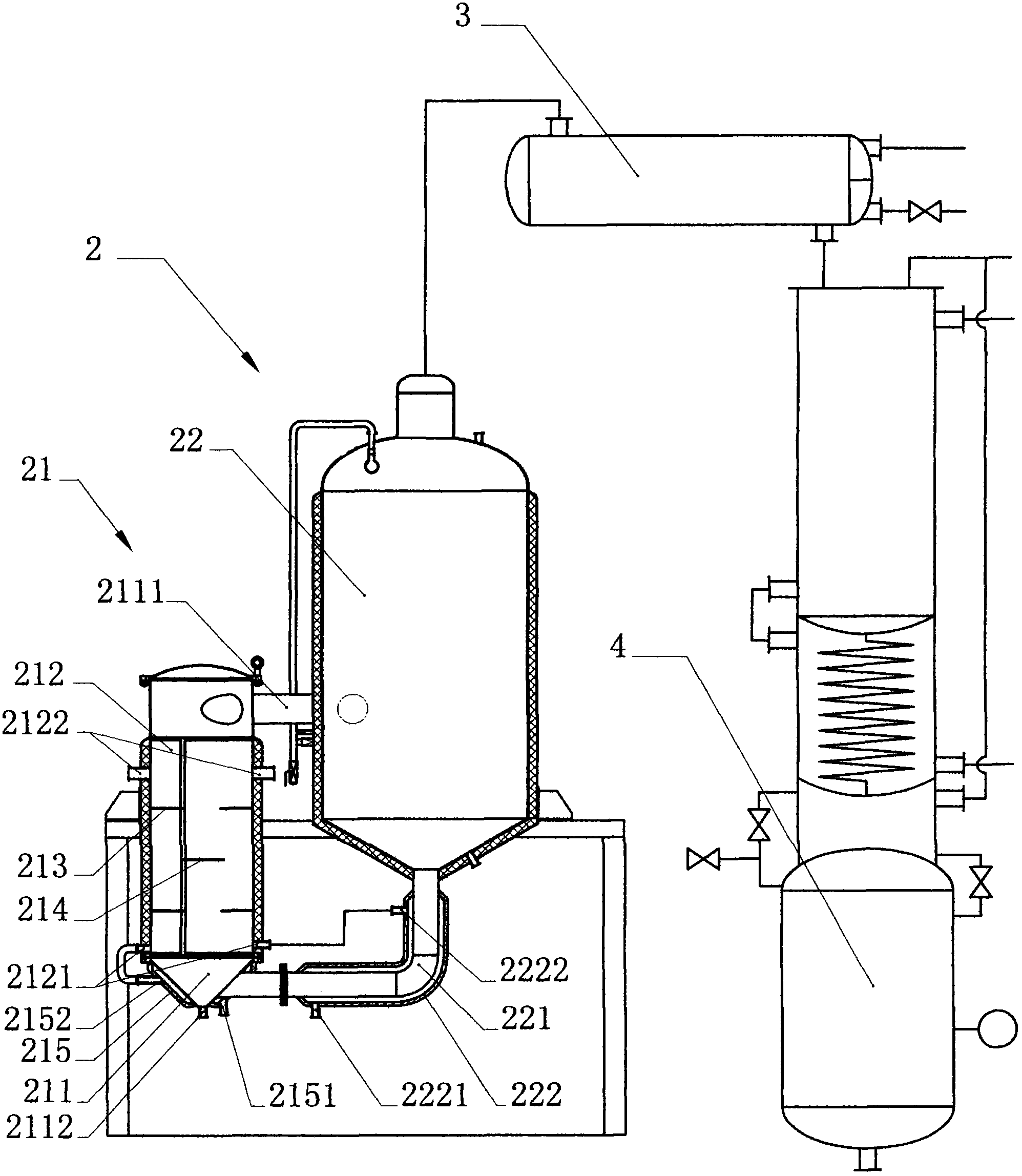

[0015] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0016] like Figure 1 to Figure 3 As shown, the present invention is an automatic control water bath evaporation unit, which includes a heating system 1, a concentrator 2, a condenser 3 and a liquid collection tank 4, and the heating system 1 includes inlets and outlets, ports 111, 112 and return ports 113 The expansion tank 11, the water pump 12, the heater 13, the concentrator 2 include a heating chamber 21 and an evaporation chamber 22, the heating chamber 21 is provided with a material chamber 211 and a heating chamber 212, and the heating chamber 212 is provided with a heating inlet and outlet, a port 2121 , 2122, the material chamber 211 is connected to the evaporation chamber 22 through the connecting pipe 2111, the bottom of the evaporation chamber 22 is provided with a circulation pipe 221 connected to the material chamber 211, the outlet of the exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com