Detection device and working method thereof

A detection device and detection unit technology, applied in mechanical depth measurement, printing, printing presses, etc., can solve problems such as inability to accurately detect pressure conditions, affecting the normal operation of equipment, limited contact area, etc., achieving low cost, easy maintenance, and response. Sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

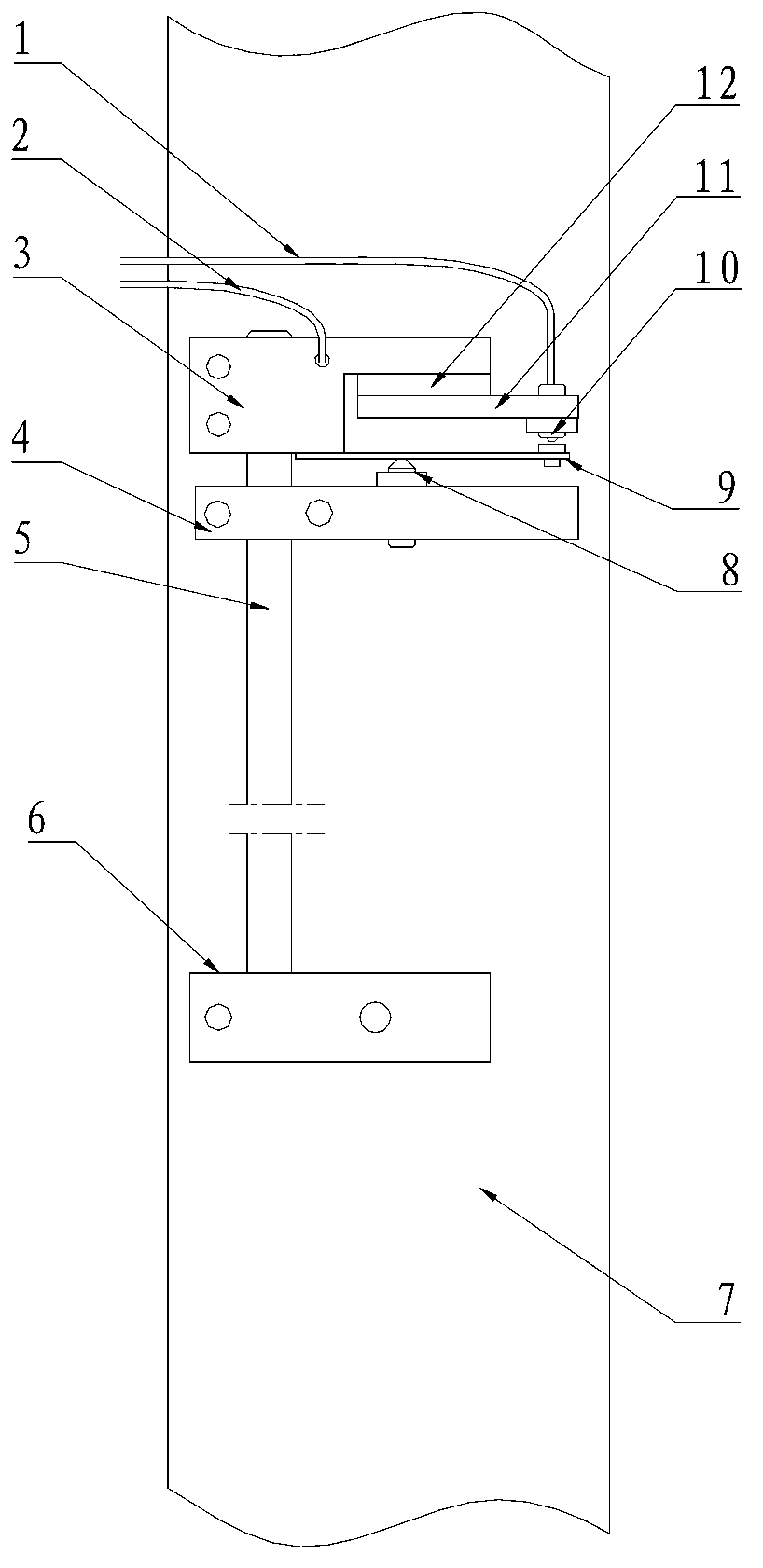

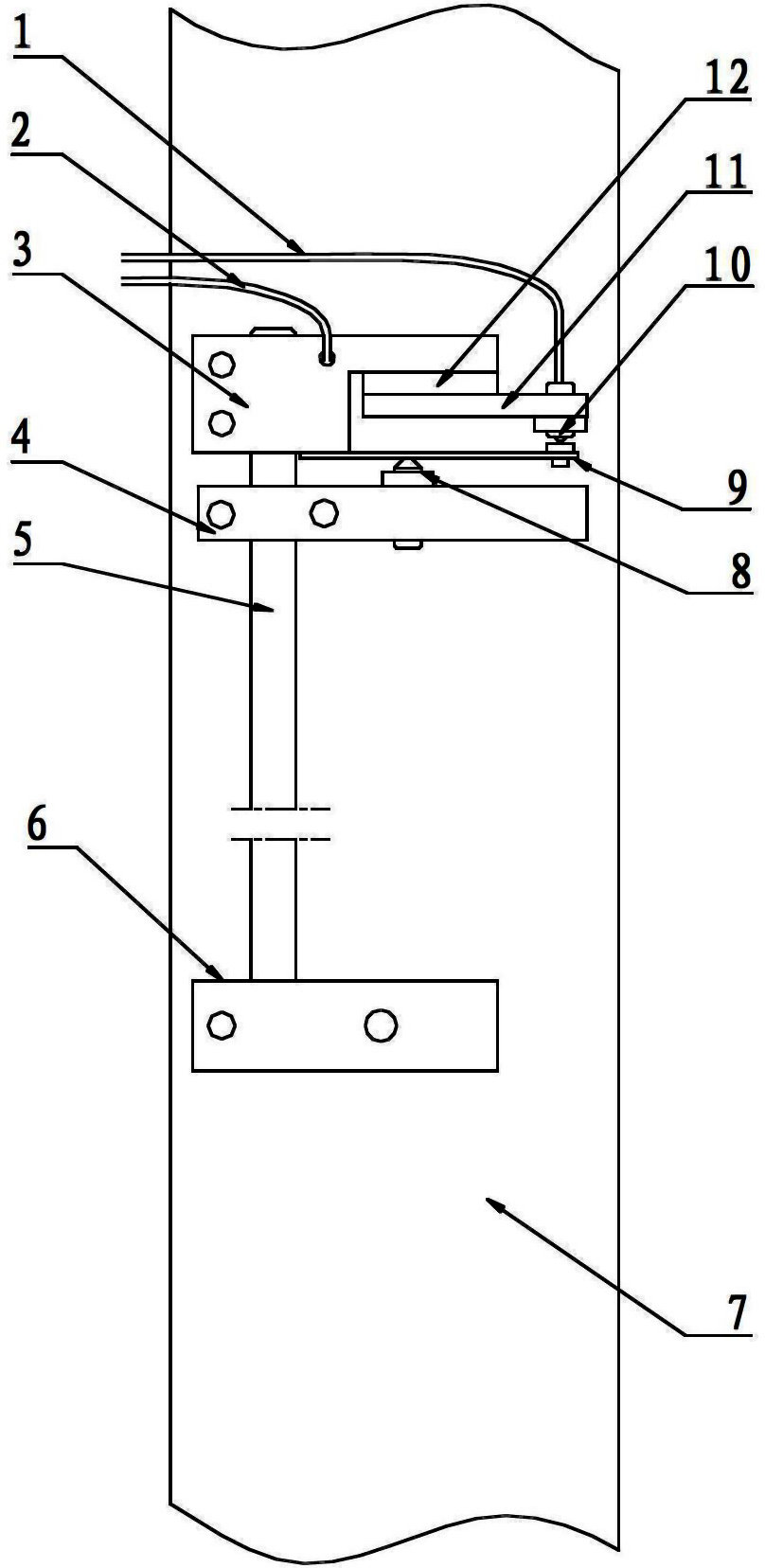

[0019] Such as figure 1 Shown: a detection device, including a sliding rod 5, a fixed block 6 and a set of detection units;

[0020] The detection unit includes a trigger block signal line 1, a spring leaf signal line 2, a connection block 3, an adjustment block 4, a top wire 8, a spring leaf 9, a positioning bead 10, a trigger block 11 and an insulating pad 12;

[0021] The fixing block 6 and the adjusting block 4 in the detection unit are fixedly connected to the wall panel 7;

[0022] The length of the sliding rod 5 is related to the deformation area of the wall panel 7, and the part of the sliding rod 5 between the fixed block 6 and the adjusting block 4 is the easily deformable area of the wall panel 7;

[0023] The adjusting block 4 and the connecting block 3 are each provided with an opening, one end of the sliding rod 5 is fixedly connected to the fixed block 6, and the other end passes through the openings of the adjusting block 4 and the connecting block 3 in turn; the co...

Embodiment 2

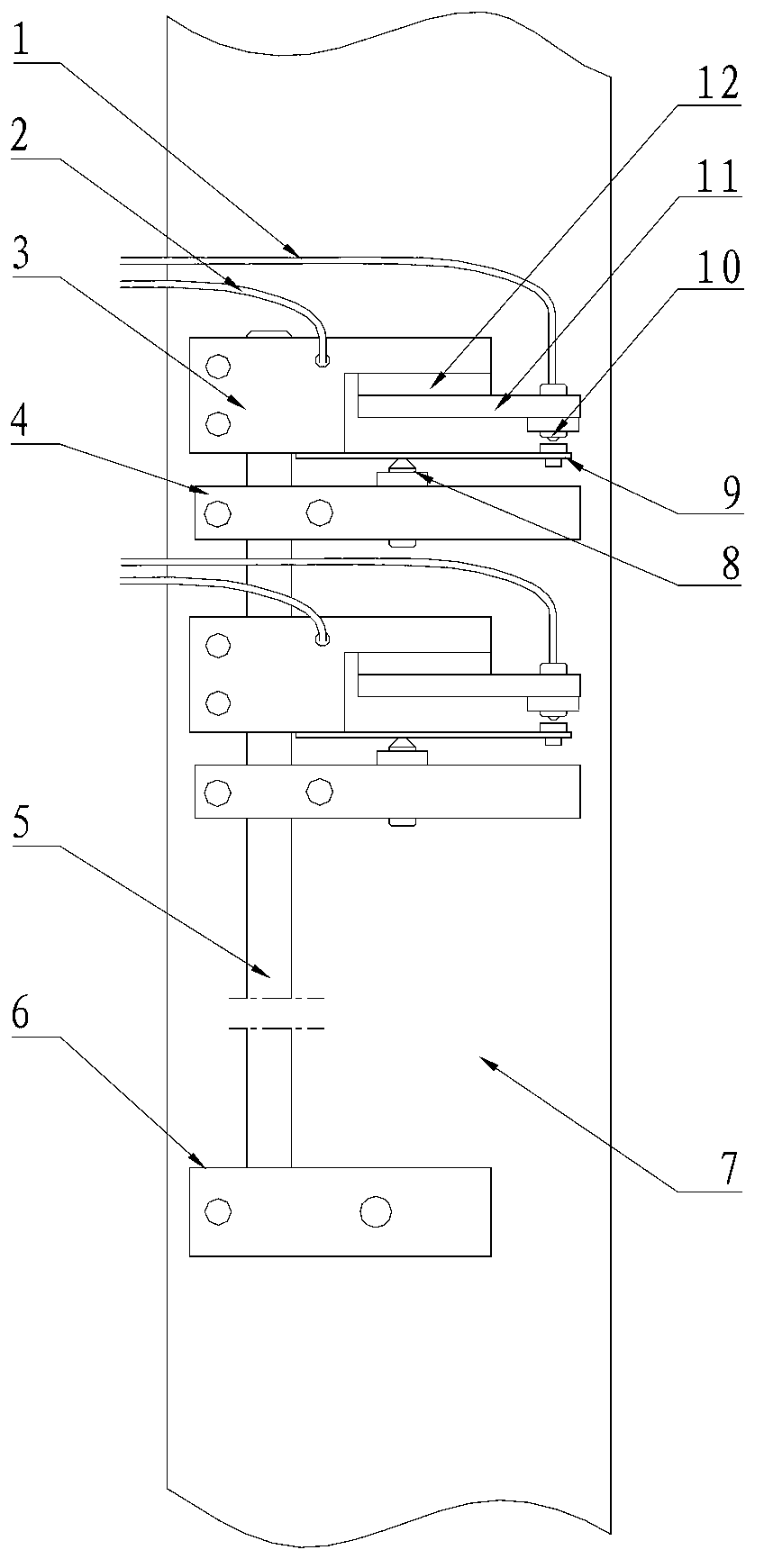

[0031] When the upper and lower platforms are used for hot stamping, the wall panel 7 will often undergo thermal expansion and deformation due to the high temperature during hot stamping. In order to accurately determine whether the alarm is caused by the thermal expansion and deformation of the wall panel 7, or the pressure on the upper and lower platforms increases instantaneously, the wall panel 7 occurs. For alarms caused by deformation, two sets of detection units need to be installed at this time. The specific plan is as follows:

[0032] Such as figure 2 As shown, a detection device includes a sliding rod 5, a fixed block 6 and two sets of detection units;

[0033] The detection unit includes a trigger block signal line 1, a spring leaf signal line 2, a connection block 3, an adjustment block 4, a top wire 8, a spring leaf 9, a positioning bead 10, a trigger block 11 and an insulating pad 12;

[0034] The fixing block 6 and the adjusting block 4 in the detection unit are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com