Impact needle of spray head of large character code spraying machine

A technology of inkjet printers and large characters, which is applied in printing and other directions, can solve the problems of uneven ink distribution, poor visual effect, and low work efficiency, and achieve the effects of reducing equipment maintenance costs, prolonging service life, and small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

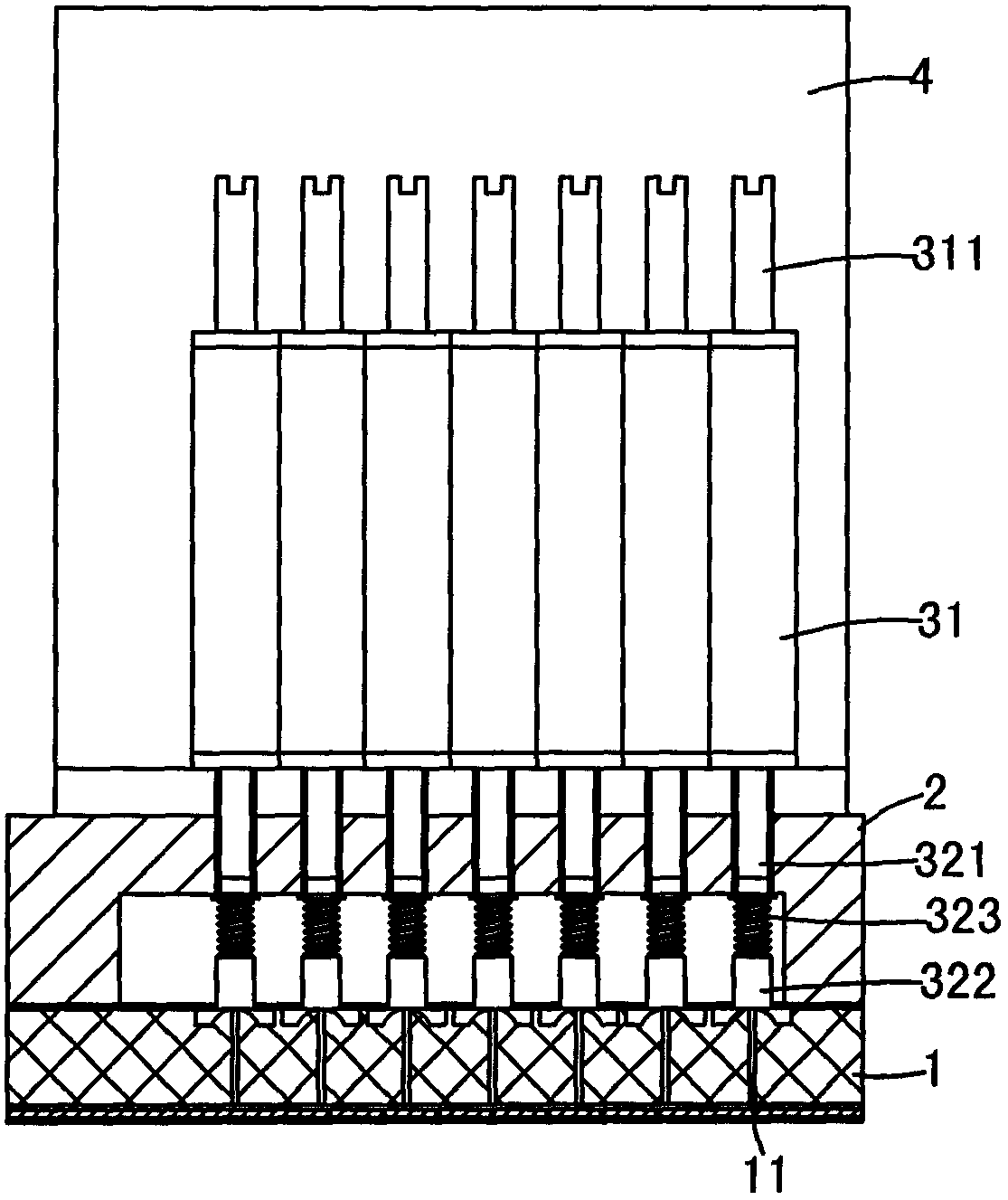

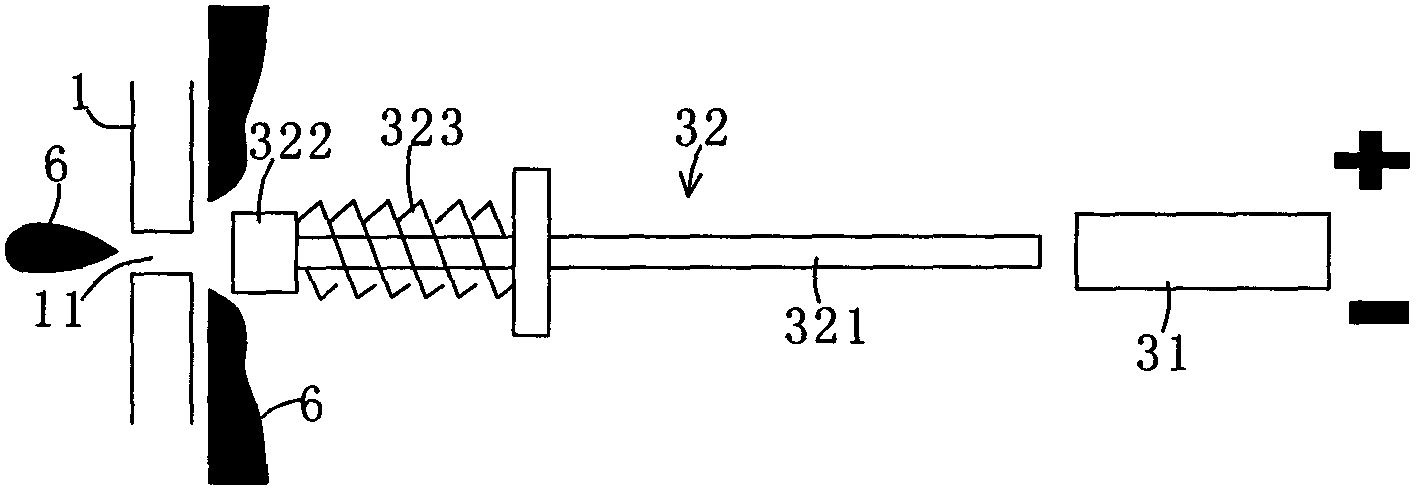

[0013] The nozzle striker structure of the large character inkjet printer proposed by the present invention is as follows: figure 1 , figure 2 As shown, the head of the striker 32 is located in the cavity between the upper ink tank 1 and the lower ink tank 2, the tail of the striker 32 extends into the inductance coil 31 and is connected with the moving iron core, the inductance coil 31 drives the striker 32 to move, There is a group of nozzle holes 11 in the ink tank 1, and the ink 6 can be accommodated in the cavity. The movement of the striker 32 makes the ink 6 eject from the nozzle holes 11. The striker 32 includes a needle bar 321, and the head of the needle bar 321 A bumper 322 is provided. The bumper 322 is molded by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com